7.21 Universal Shaft

7.21.1 Universal shaft – Greasing

Preconditions

☑Engine is stopped and starting disabled.

Special tools, Material, Spare parts

Designation / Use Part No. Qty.

Lithium-soap greases according to DIN2–KP K–20

NOTICE

Damage to component.

Severe material damage!

• Do not press in grease at high pressure or with hard strokes.

• Permissible lubrication pressure max. 15 bar.

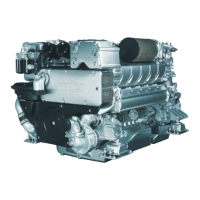

Universal shaft – Greasing

1. Remove guard from universal shaft.

2. Clean the two grease nipples on each joint

half.

3. Press grease into all nipples until it emerg-

es at the star seals and sealing rings.

4. Reinstall guard.

MW15406/17E 2014-05 | Task Description | 213

TIM-ID: 0000007659 - 003

Loading...

Loading...