WM620 Hardware User Guide

Copyright © Neoway Technology Co., Ltd

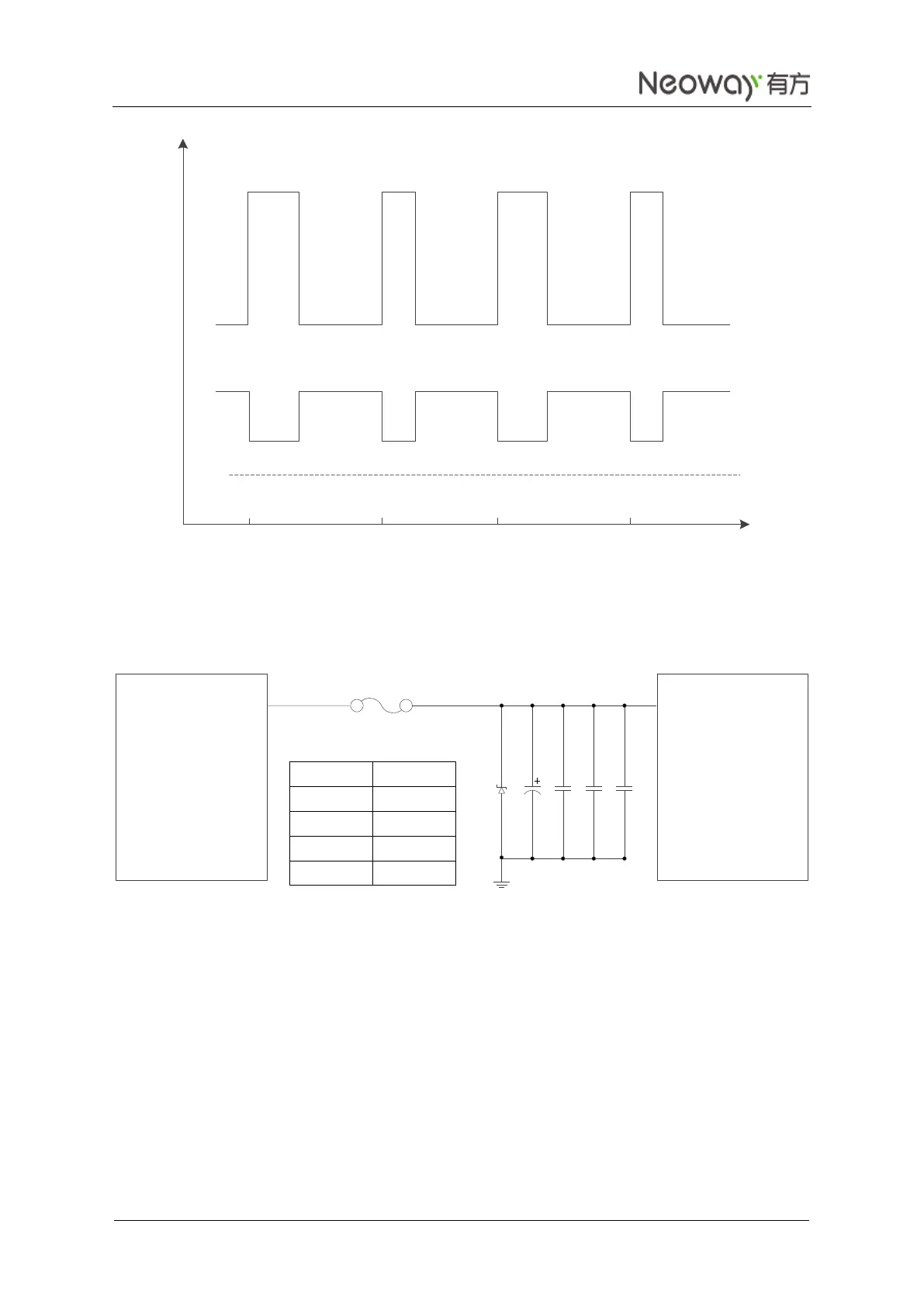

Figure 3-1 Current peaks and voltage drops

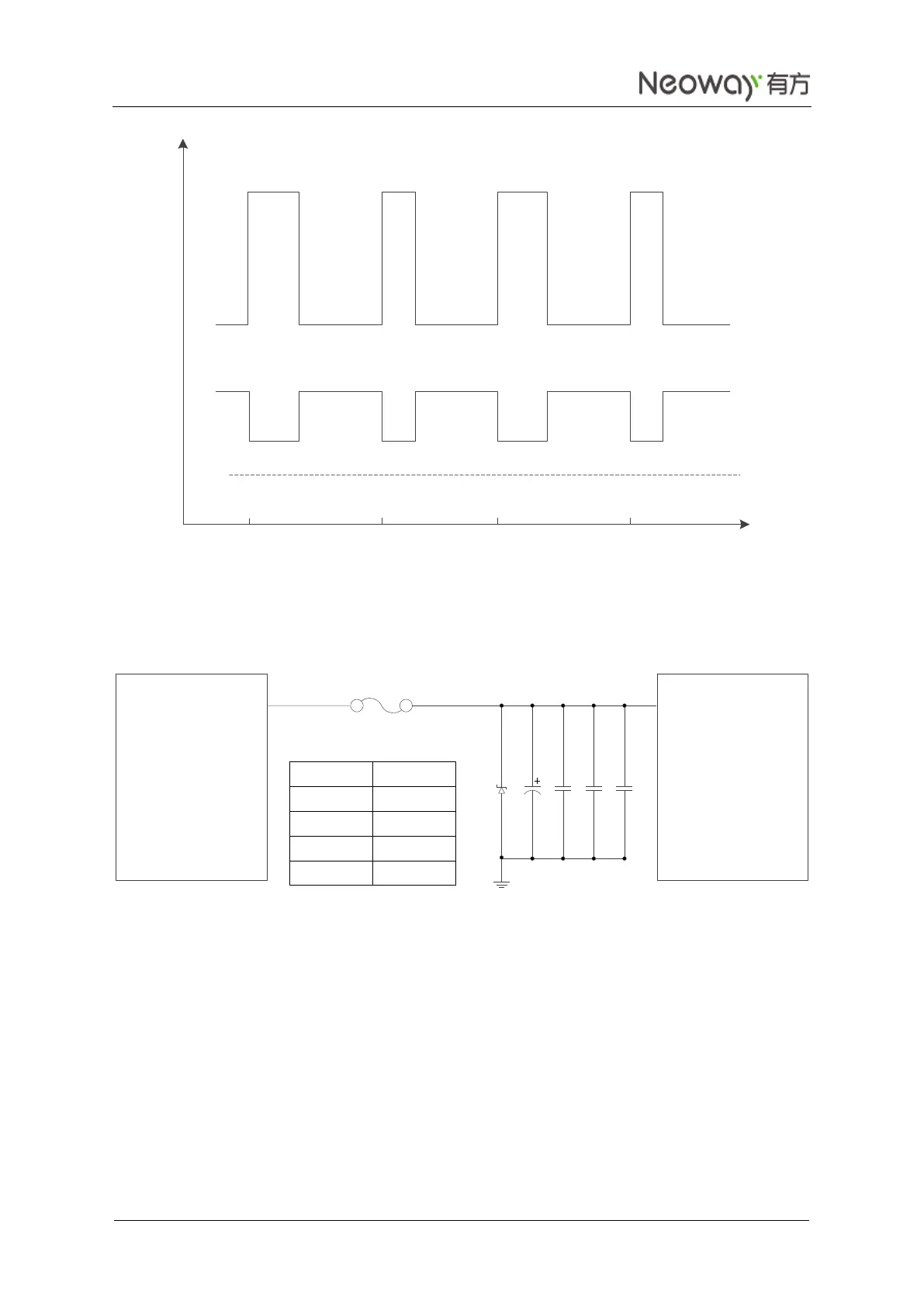

Figure 3-2 shows a recommended power supply design for the module.

Figure 3-2 Power supply design

The current test results vary with the internal impedance of the ESR capacitors and power supply. In the

above circuit, use TVS diode at D1 to enhance the performance of the module during a burst. A 100 μF

capacitor with low ESR or 470 μF aluminum capacitor is expected at C1 to reduce voltage drops during

bursts. In case of Li-ion cell battery used, a 220 μF tantalum capacitor may be applicable because the

battery has low internal impedance. In addition, add 0.1 μF, 100 pF, and 33 pF filter capacitors to filter

high frequency interference.

A controllable power supply is preferable if the module is used in harsh conditions. The WM620 module

might fail to reset in remote or unattended applications, or in an environment with great electromagnetic

interference (EMI). Users can use the EN pin on the LDO or DC/DC chipset to control the power supply

as shown in Figure 3-3 if 5 V power supply is adopted.

Keep above 3.3 V

3.3 V

0 ms

3.7 ms 7.4 ms 10.7 ms

T

2 A

Voltage

Input

Current

3.9 V

Power Supply WM620

Close to the pins

D1

C1 C2 C3 C4

VBAT

Current testing

point

I_max

C1 I_max

10uF

100uF

470uF

1000uF

2A

1.1A

0.8A

0.6A

Loading...

Loading...