BTS User Manual

Neware Technology Ltd.

http://www.newarebattery.com

1.4. BTS9 Instruction

BTS 9 system is a new generation of battery test system developed by NEWARE through continuous innovation over the

years to meet market demand. The system supports measurement of battery cell voltage and temperature, measurement of

DCIR, pulse mode, constant power charging, I2C/SMBUS protocol, interaction with intelligent battery, intelligent charging

and so on.

The BTS9 battery test system is based on the existing office network and computer of enterprises, units, laboratories, and

so on. The operation is simple. Users can remotely log in to the system through the Internet to perform various operations.

C/S network system structure and database management test data, centralized control of multiple connected devices, and

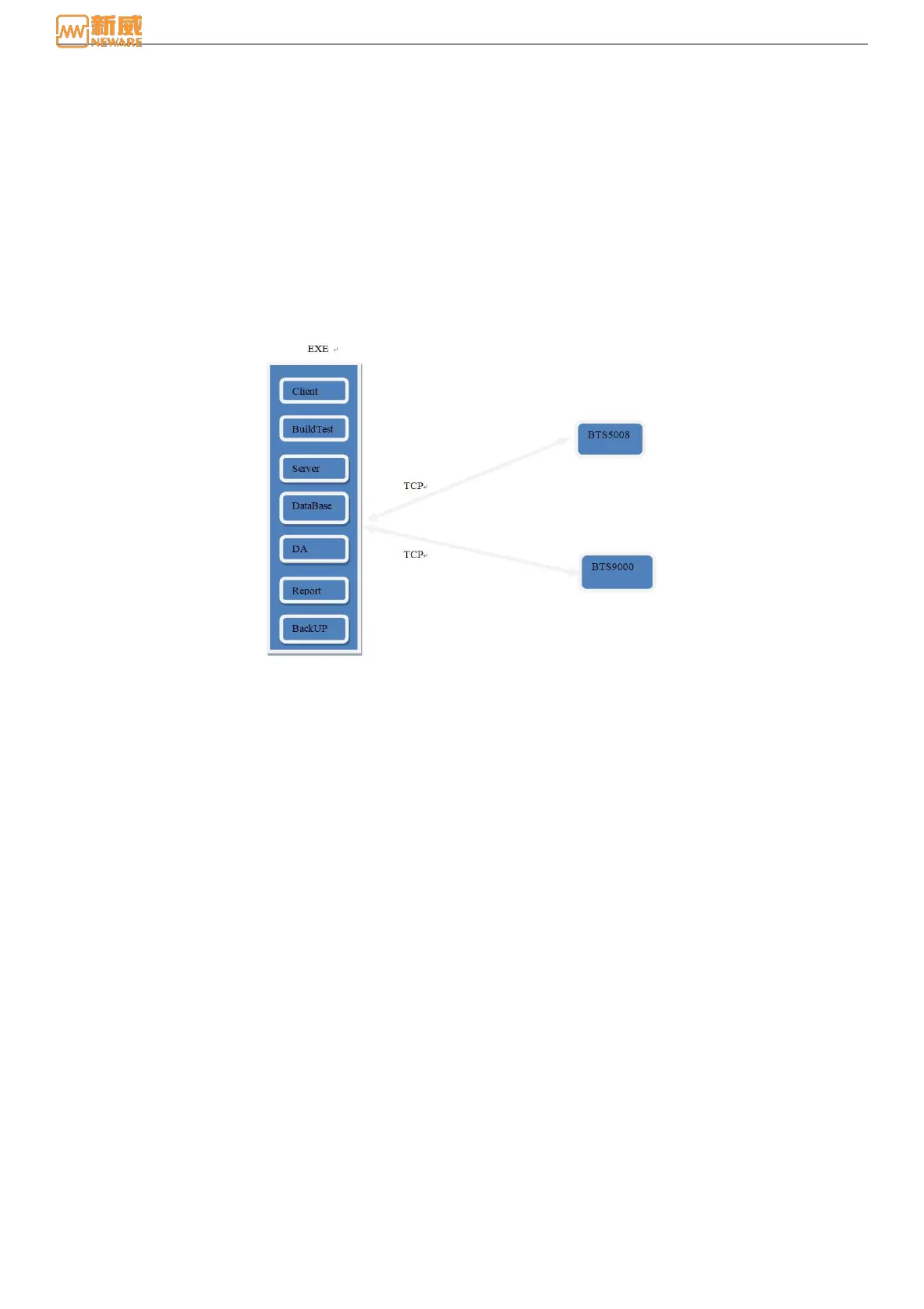

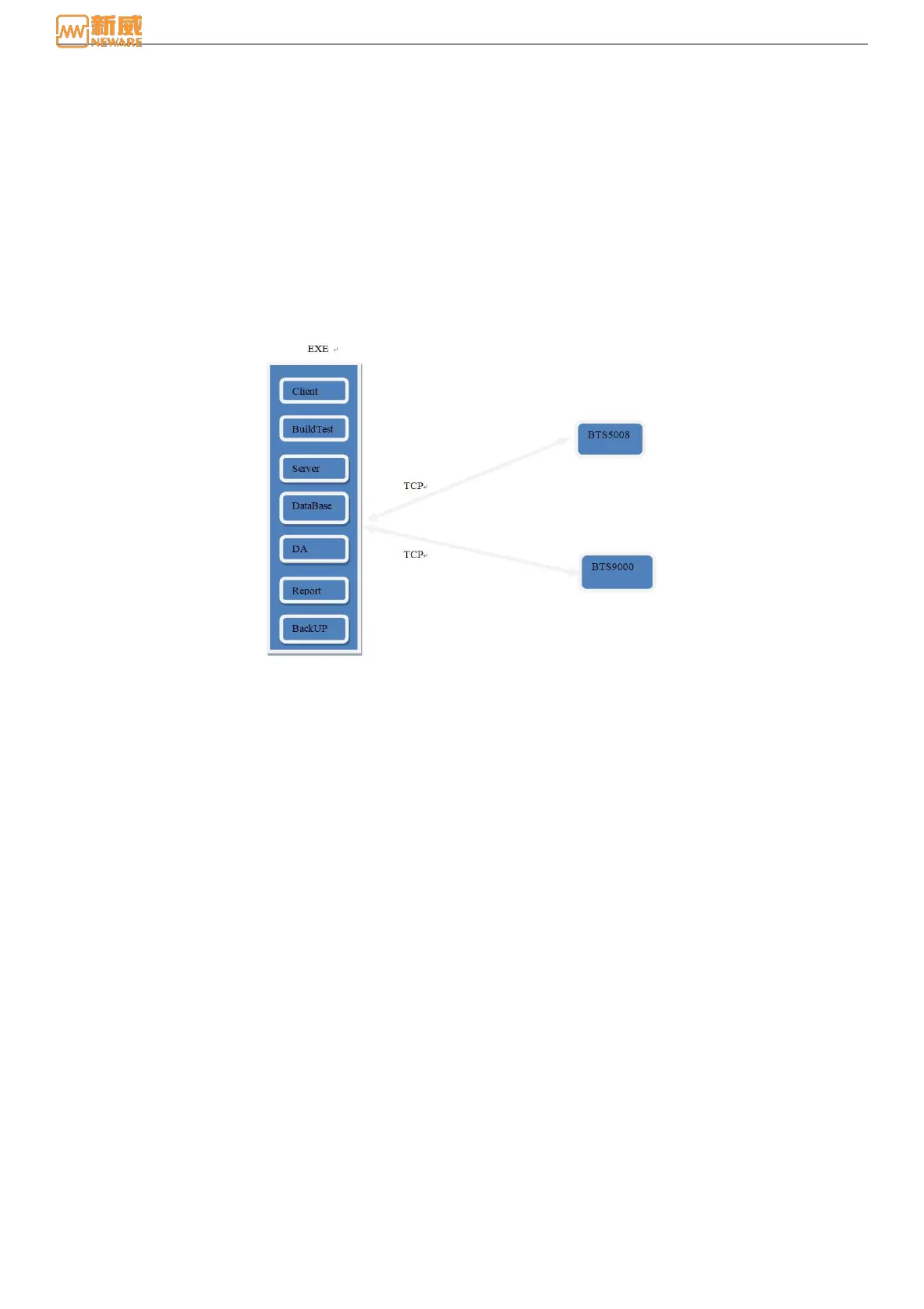

centralized management analysis and statistics of all the data. Figure 1-1 shows the diagram of the BTS9 battery detection

system.

Figure 1-1 BTS9 Battery Test System Block Diagram

BTS9 battery test system is constructed by the upper-machine, mid-machine, and channel control module (as shown in the

figure above). The mid-machine is compatible with BTS5008 and BTS9000 models. The mid-machine has its own test

channel, which can test the battery.

1.5. System Features

BTS9 battery test system adopts an advanced three-level control architecture (upper-machine, mid-machine, and

lower-machine). The mid-machine centrally manages the test process and data transmission of all the lower-machines,

realizing the real-time response of power failure protection, abnormal test protection, test mode switch and recording of all

test events. Each channel has independent over-current, over-voltage, under-voltage, overload, monomer voltage, auxiliary

temperature, and other protection conditions to ensure the high reliability and safety of test data.

The system has a rigorously constructed software testing platform to ensure that all circuit units, software modules, and

structural designs have 100% complete coverage of principle verification and function and performance testing. All

equipment is subjected to a vibration test before leaving the factory to ensure that it will not be damaged during

transportation.

Hardware Features

1. Advanced hardware circuit architecture, modular design, and channel independent control.

2. Sophisticated calibration system.

3. The clamps acquired numbers of patterns, and the clamps is customizable with a wide selection.

4. Independent ventilation and heat dissipation design to effectively improve the stability of system.

5. With four pins input socket, the test range is wide and the test accuracy is high

6. Capable of comprehensive battery testing.

7. Supports channel mapping and AUX channel binding.

8. The independent grounding terminals, cables, and PCB boards that made of flame retardant materials.

9. The system is equipped with an anti-reverse connection module to prevent the electrode of the battery from being

connected reversely to ensure the safety of testing and production.

10. The independent double loop control mode of the hardware, CC to CV smooth transition, can prevent the current

Loading...

Loading...