20 – ENGLISH

7.4 SPECIAL FUNCTIONS

7.4.1 “Move anyway” function

This function can be used to operate the automation even one

or more some safety devices fail to work properly or are out of

order. The automation can be controlled in “hold-to-run” mode

by proceeding as follows:

1. send a command to operate the gate, using a transmitter

or key selector, etc. If everything functions properly, the

gate will move normally, otherwise proceed with point 2

2. within 3 seconds, press the control again and hold it down

3. after roughly 2 seconds, the gate will complete the re-

quested manoeuvre in “hold-to-run” mode, in other

words, it will continue to move so long as the control is

held down.

l

When the safety devices fail to work, the warn-

ing light will emit a few ashes to signal the

type of problem. To verify the type of anom-

aly, consult the “TROUBLESHOOTING...

(troubleshooting guide)” chapter.

7.4.2 “Maintenance notice” function

This function noties the user when the automation needs a

maintenance check. The number of manoeuvres after which the

signal is triggered can be selected among 8 levels, through the

“Maintenance notice” adjustable parameter (see paragraph “

Level 2 programming (adjustable parameters)“).

The maintenance request signal is given through a lamp con-

nected to the “Flash” or “EL” output, when one of these two

outputs is programmed – with the Oview programmer – as a

“Maintenance Indicator” (see paragraph “Level 2 program-

ming (adjustable parameters)“).

l

The maintenance indicator emits the signals shown

in “Table 7” based on the number of manoeuvres

completed with respect to the set limit.

Table 7

MAINTENANCE NOTICE THROUGH FLASH AND MAINTENANCE

INDICATOR

Number of manoeuvres Maintenance indicator signal

Below 80% of the limit

Lit for 2 seconds at the start of the

opening manoeuvre

Between 81% and 100%

of the limit

Flashes for the entire duration of the

manoeuvre

Exceeding 100% of the

limit

Flashes always

7.4.3 Verifying the number of manoeuvres completed

The “Maintenance notice” function can be used to verify the

number of manoeuvres completed as a percentage of the set

limit.

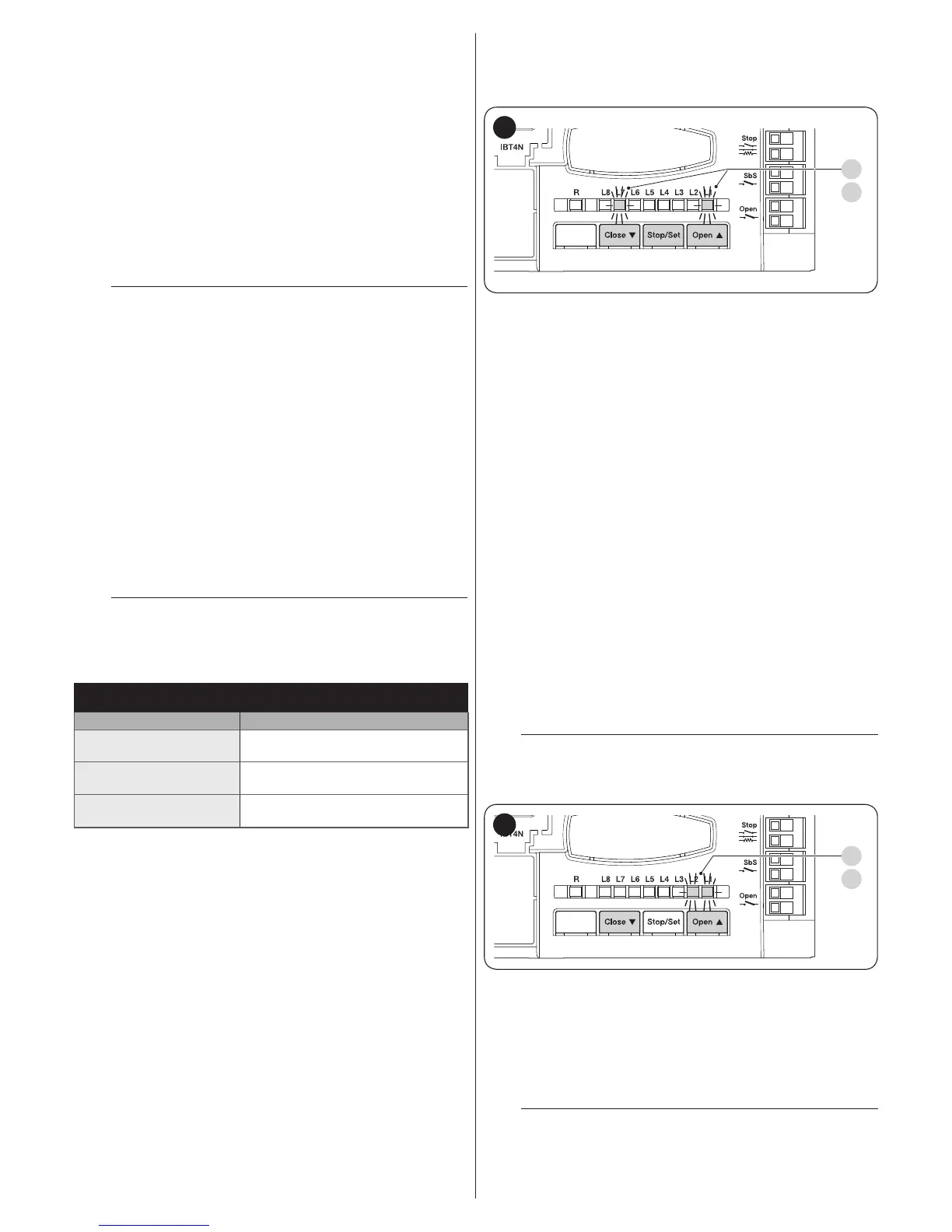

STOP SBS OPEN

L1

L7

37

To do this:

1. press and hold the [Stop/Set] button until LED “L1” starts

ashing

2. release the [Stop/Set] button when LED “L1” starts ash-

ing

3. press the [Open

p

] or [Close

q

] button to shift the ash-

ing LED to “L7”, that is, the “entry LED” for the “Mainte-

nance notice” parameter

4. press and hold the [Stop/Set] button. With the [Stop/Set]

button pressed:

– wait roughly 3 seconds until the LED representing the

current level of the “Maintenance notice” parameter

lights up

– press and immediately release the [Open

p

] and

[Close

q

] buttons

– the LED corresponding to the selected level will ash

several times; the number of ashes indicates the

percentage of manoeuvres completed (in multiples of

10%) with respect to the set limit. For example: with

the maintenance notice set to L6, namely 10,000, if the

viewing LED ashes 4 times, it means that 40% of the

manoeuvres has been reached (i.e. between 4,000 and

4,999 manoeuvres). The LED will not ash unless 10%

of the manoeuvres have been completed.

5. release the [Stop/Set] button.

7.5 MEMORY DELETION

m

The procedure described below restores the con-

trol unit’s default settings. All the custom settings

will be lost.

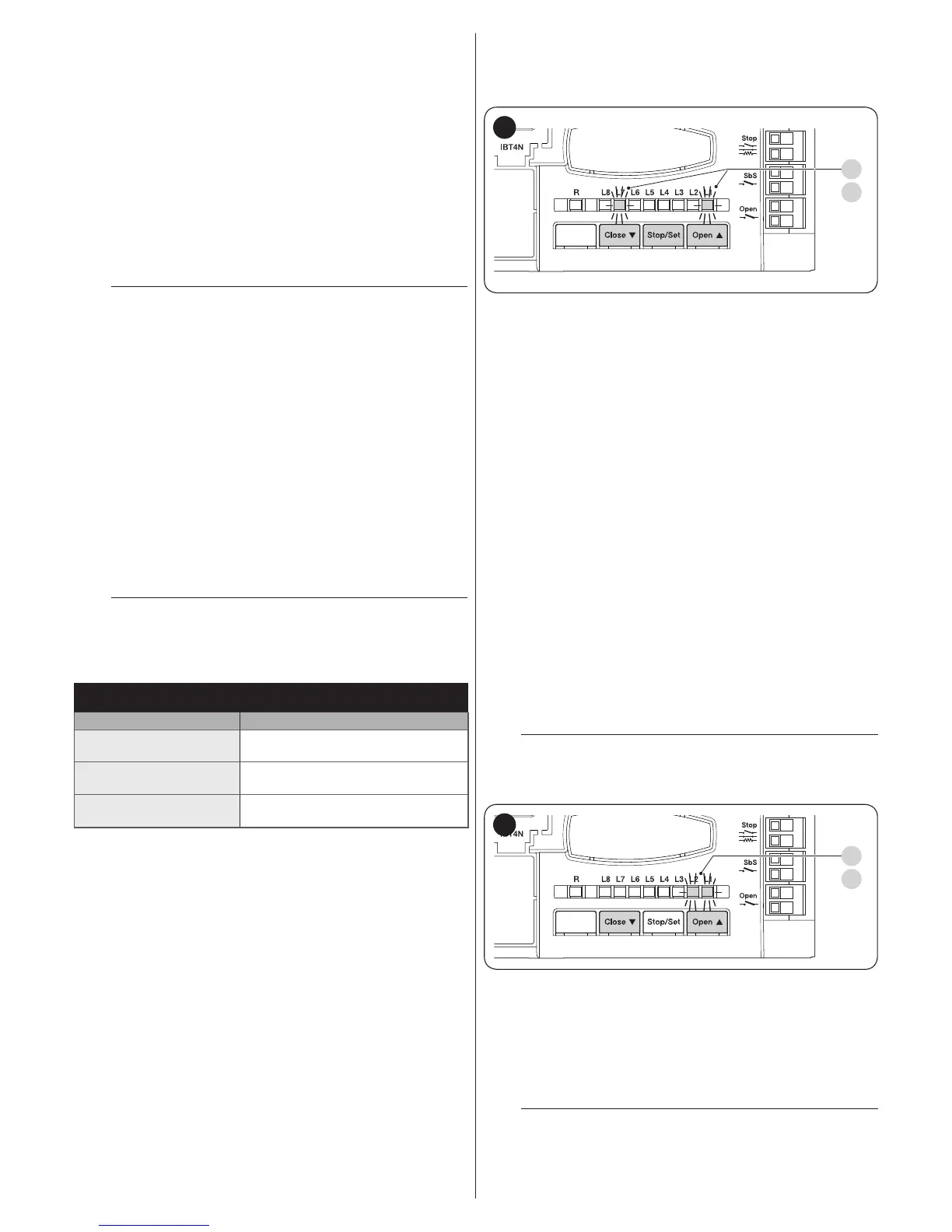

STOP SBS OPEN

L1

L2

38

To delete the control unit’s memory and restore all the default

settings, proceed as described below:

1. press and hold the [Open

p

] and [Close

q

] buttons until

the programming LEDs “L1-L8” light up (after roughly 3

seconds)

2. release the buttons

3. if the operation was successful, the programming LEDs

“L1-L8” ash quickly for 3 seconds.

l

The following will be cancelled: mechanical stop

positions, Level 1 and Level 2 settings.

Loading...

Loading...