Revision 2

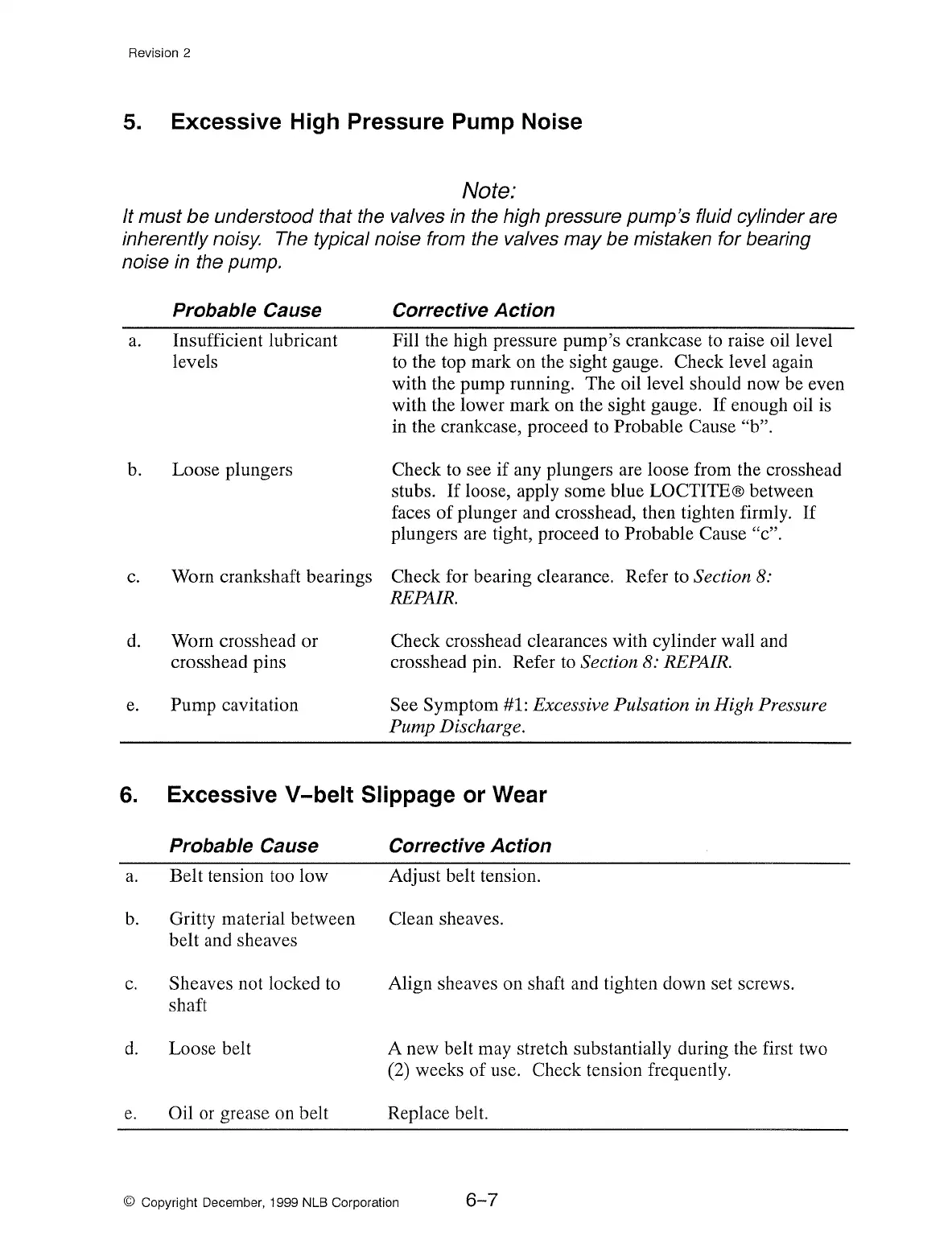

5.

Excessive High Pressure Pump Noise

Note:

It must

be

understood that the valves

in

the high pressure pump's fluid cylinder are

inherently noisy. The typical noise from the valves

may

be mistaken for bearing

noise in the pump.

Probable Cause

a.

Insufficient lubricant

levels

b. Loose plungers

Corrective Action

Fill the high pressure pump's crankcase

to

raise oil level

to

the top mark on the sight gauge. Check level again

with the pump running. The oil level should now be even

with the lower mark on the sight gauge.

If

enough oil is

in the crankcase, proceed

to

Probable Cause "b".

Check

to

see if any plungers are loose from the crosshead

stubs.

If

loose, apply some blue LOCTITE® between

faces

of

plunger and crosshead, then tighten firmly.

If

plungers are tight, proceed

to

Probable Cause "c".

c.

Worn crankshaft bearings Check for bearing clearance. Refer

to

Section 8:

d.

Worn crosshead or

crosshead pins

e.

Pump cavitation

REPAIR.

Check crosshead clearances with cylinder wall and

crosshead pin. Refer

to

Section 8: REPAIR.

See Symptom #1: Excessive Pulsation

in

High Pressure

Pump

Discharge.

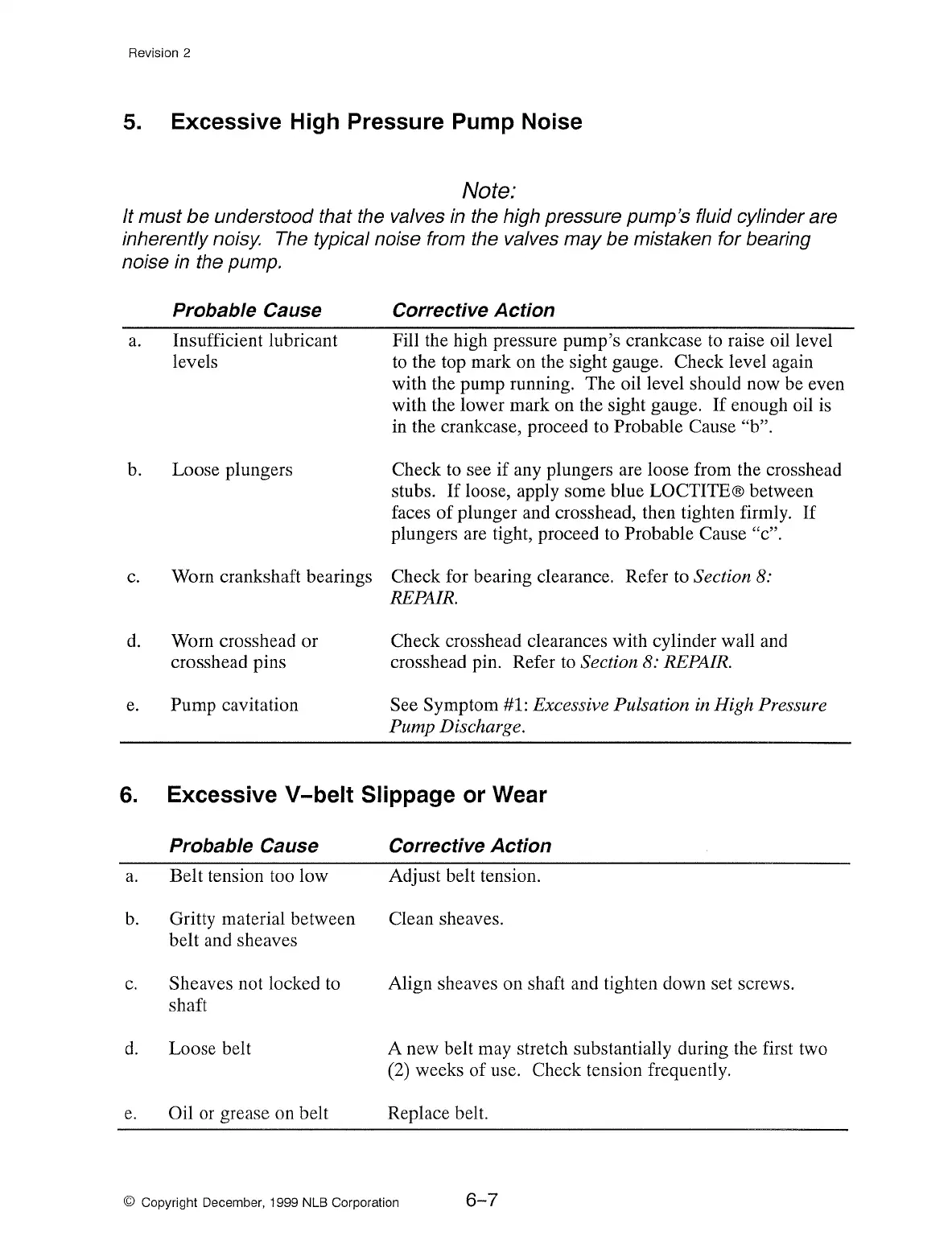

6.

Excessive V-belt Slippage or Wear

Probable Cause Corrective Action

a.

Belt tension too low Adjust belt tension.

b.

Gritty material between Clean sheaves.

belt and sheaves

c.

Sheaves not locked

to

Align sheaves on shaft and tighten down set screws.

shaft

d.

Loose belt A new belt may stretch substantially during the first two

(2) weeks of use. Check tension frequently.

e.

Oil

or

grease on belt Replace belt.

© Copyright December, 1999 NLB Corporation

6-

7

Loading...

Loading...