Revision 3

IV.

Lubrication Instructions

Any special lubricating instructions for vendor equipment in the high pressure water jetting

units are covered in the MANUFACTURERS' LITERATURE section in this manual.

Manufacturer's recommendations set forth for this equipment must be followed for that

equipment.

Unless specified otherwise, service intervals specified are for operating hours in moderate

temperatures. Adjust service intervals accordingly for operation in abnormal conditions.

The suggested lubrication instructions and service intervals are for illustration purposes only.

NLB does not warrant that adherence to these suggestions will necessarily result in proper

lubrication. NLB disclaims any responsibility for equipment and/or accessory failure that is

due to the lack

of

or improper lubrication. NLB suggests that you consult with your

lubrication supplier for recommendations that will suit your specific requirements.

Note:

Manufacturer's nameplate data take precedent over the following suggestions.

Drain lubricating oil only when

it

is

hot

and

the contaminants are

in

suspension.

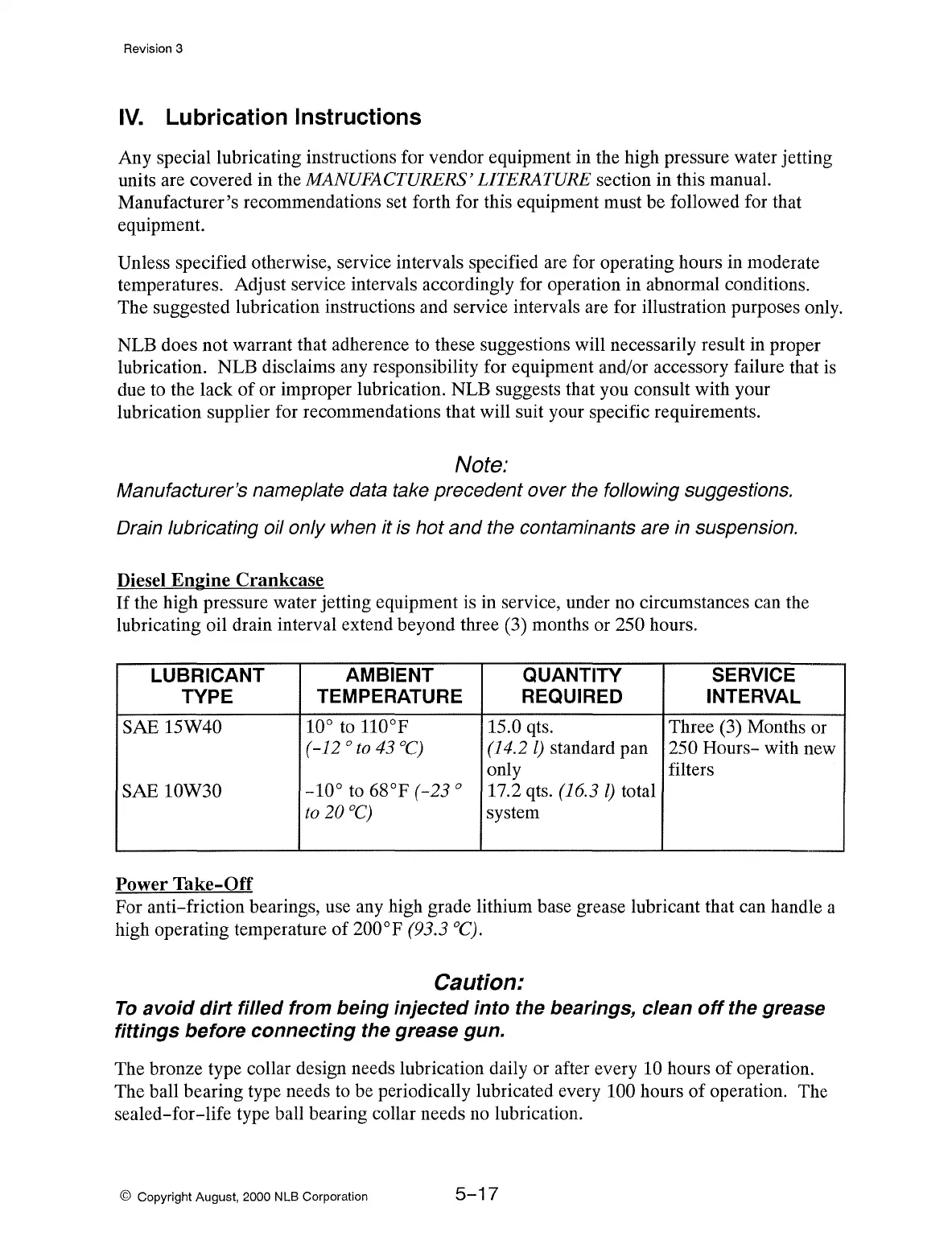

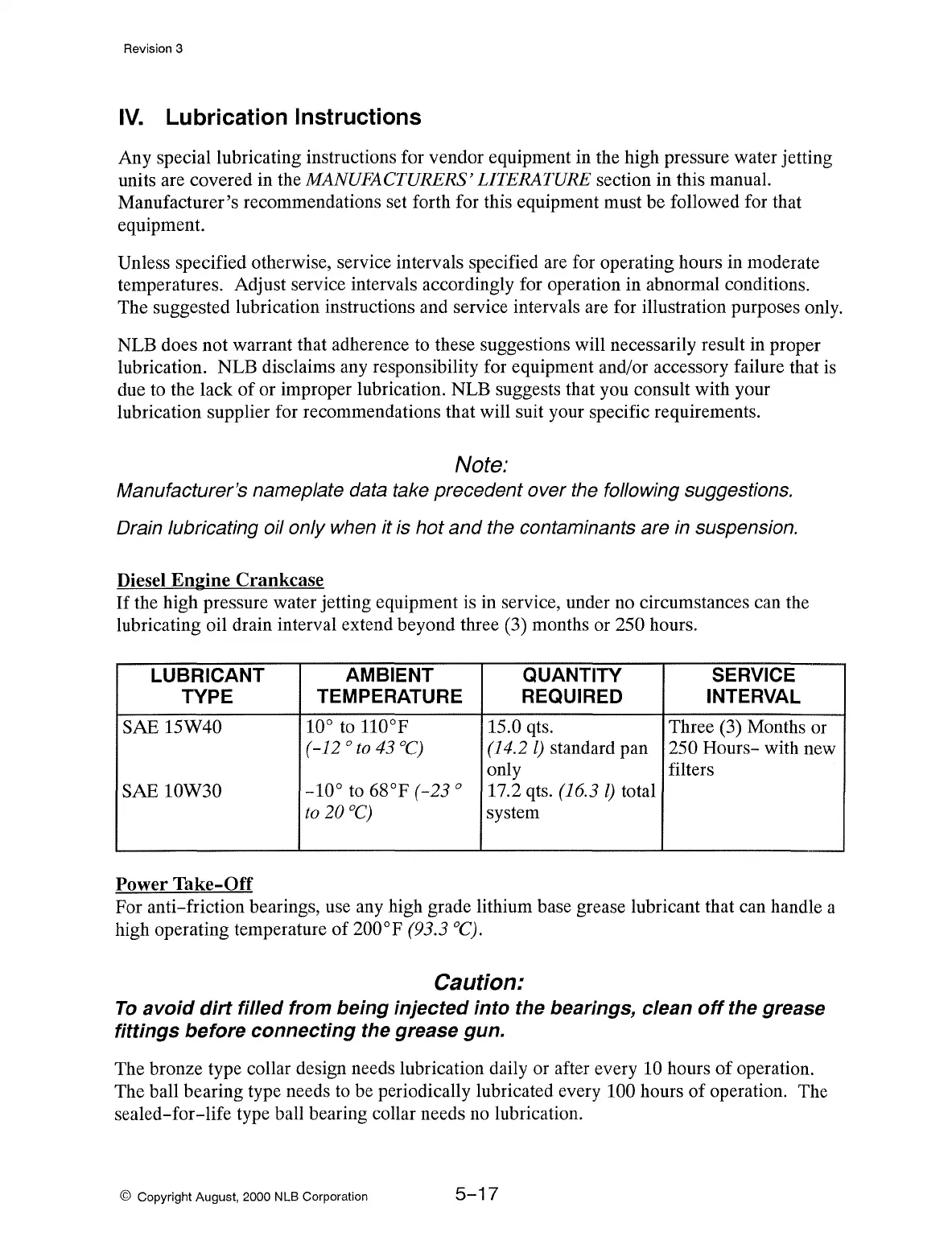

Diesel

Engine

Crankcase

If

the high pressure water jetting equipment is in service, under no circumstances can the

lubricating oil drain interval extend beyond three (3) months or

250 hours.

LUBRICANT

AMBIENT

QUANTITY SERVICE

TYPE

TEMPERATURE

REQUIRED INTERVAL

SAE 15W40

10°

to 110°F

15.0

qts. Three (3) Months or

(-12

° to 43

°C)

(14.2

l)

standard pan

250 Hours- with new

only filters

SAE 10W30

-10°

to

68°F

(-23

°

17.2 qts. (16.3

l)

total

to

20

°C)

system

Power

Take-Off

For anti-friction bearings, use any high grade lithium base grease lubricant that can handle a

high operating temperature

of

200°F (93.3 °C).

Caution:

To

avoid

dirt

filled from being injected

into

the bearings, clean

off

the grease

fittings

before

connecting

the grease gun.

The bronze type collar design needs lubrication daily or after every 10 hours

of

operation.

The ball bearing type needs to be periodically lubricated every

100 hours

of

operation. The

sealed-for-life type ball bearing collar needs no lubrication.

© Copyright August, 2000 NLB Corporation

5-17

Loading...

Loading...