Revision 1

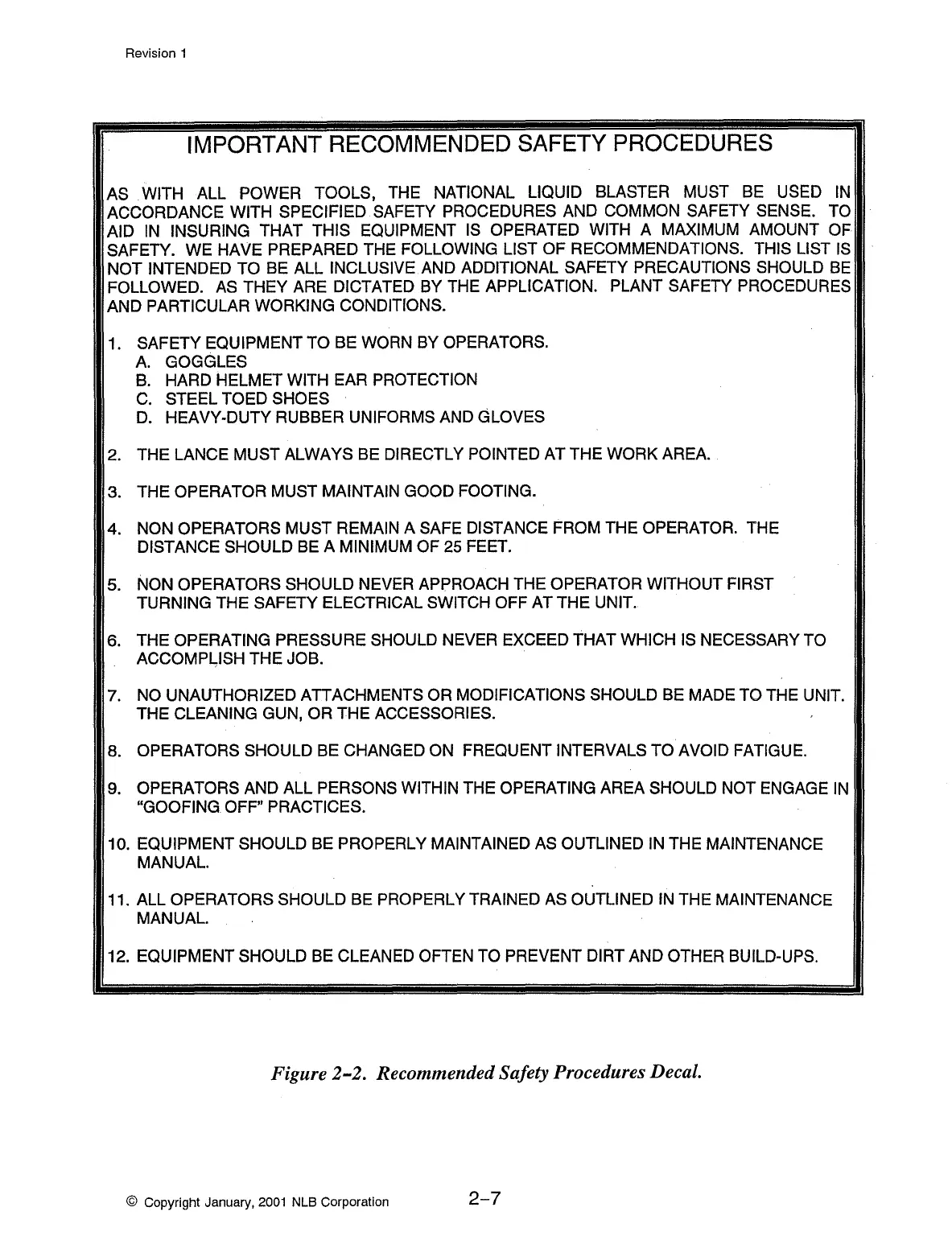

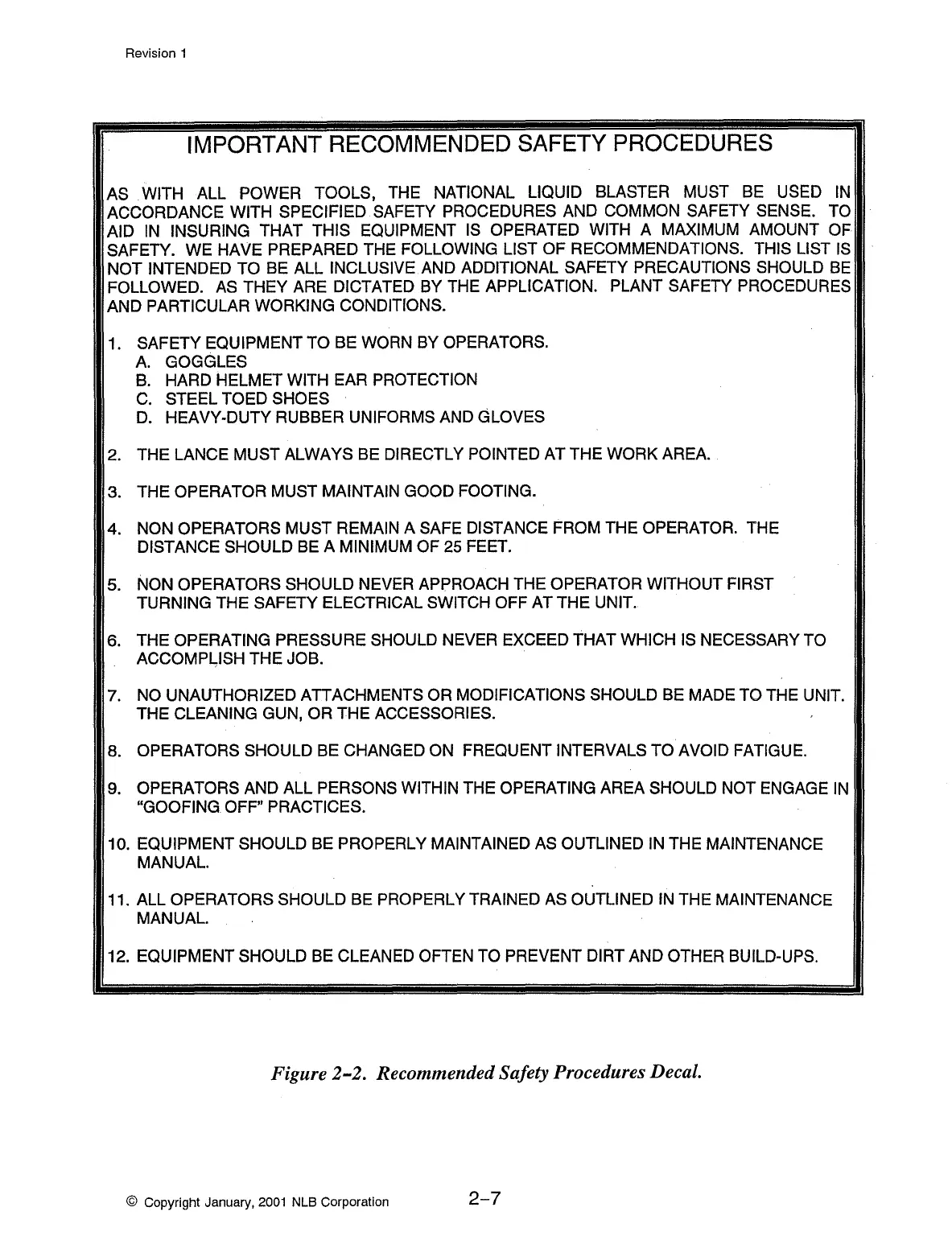

IMPORTANT RECOMMENDED SAFETY PROCEDURES

AS

WITH ALL POWER

TOOLS,

THE NATIONAL LIQUID BLASTER MUST BE USED

IN

ACCORDANCE WITH SPECIFIED SAFETY PROCEDURES AND COMMON SAFETY SENSE. TO

AID IN INSURING

THAT

THIS

EQUIPMENT

IS

OPERATED WITH A MAXIMUM AMOUNT OF

SAFETY.

WE

HAVE PREPARED THE FOLLOWING LIST

OF

RECOMMENDATIONS. THIS LIST

IS

NOT

INTENDED

TO

BE ALL INCLUSIVE AND ADDITIONAL SAFETY PRECAUTIONS SHOULD BE

FOLLOWED. AS

THEY

ARE DICTATED BY THE APPLICATION. PLANT SAFETY PROCEDURES

AND

PARTICULAR WORKING CONDITIONS.

1.

SAFETY EQUIPMENT

TO

BE WORN BY OPERATORS.

A. GOGGLES

B. HARD HELMET WITH EAR PROTECTION

C.

STEEL TOED SHOES

D. HEAVY-DUTY RUBBER UNIFORMS AND GLOVES

2. THE LANCE

MUST

ALWAYS BE DIRECTLY POINTED AT THE WORK AREA.

3. THE

OPERATOR MUST MAINTAIN GOOD FOOTING.

4. NON OPERATORS MUST REMAIN A SAFE DISTANCE FROM THE OPERATOR. THE

DISTANCE SHOULD BE A MINIMUM

OF

25 FEET.

5. NON OPERATORS SHOULD NEVER APPROACH THE OPERATOR WITHOUT FIRST

TURNING

THE SAFETY ELECTRICAL SWITCH OFF

AT

THE

UNIT.

6. THE OPERATING PRESSURE SHOULD NEVER EXCEED

THAT

WHICH IS NECESSARY

TO

ACCOMPl.,ISH

THE

JOB.

7. NO UNAUTHORIZED ATTACHMENTS OR MODIFICATIONS SHOULD BE MADE

TO

THE UNIT.

THE

CLEANING GUN,

OR

THE

ACCESSORIES.

8. OPERATORS SHOULD BE CHANGED ON FREQUENT INTERVALS

TO

AVOID FATIGUE.

9. OPERATORS AND ALL PERSONS WITHIN THE OPERATING AREA SHOULD NOT ENGAGE IN

"GOOFING OFF" PRACTICES.

10. EQUIPMENT SHOULD BE PROPERLY MAINTAINED AS OUTLINED IN THE MAINTENANCE

MANUAL.

11. ALL OPERATORS SHOULD BE PROPERLY TRAINED AS OUTLINED

IN

THE MAINTENANCE

MANUAL.

12. EQUIPMENT SHOULD BE CLEANED OFTEN

TO

PREVENT DIRT AND OTHER BUILD-UPS.

Figure 2-2. Recommended Safety Procedures Decal.

© Copyright January,

2001

NLB Corporation

2-7

Loading...

Loading...