Revision 1

a.

Attendance - The system shall never be left unattended when pressurized.

b.

Multiple operation - When more than one (1) shotgunning operation is being

performed within the same area, a physical barrier shall be installed or adequate

spacing between operators shall be maintained

to

prevent the possibility

of

injury from

the high pressure water.

c.

Target holding - Objects

to

be cleaned shall never be held manually.

d.

Connection protection - The point where the hose connects to the gun shall be

shrouded by a protective device, (e.g., heavy duty hose, shoulder guard, etc.,) so as

to

prevent injury

to

operator should hose, pipe or fitting rupture.

e.

Minimum length- Where practicable, the minimum length

of

the shotgun lance

extension should be four (4) feet

(1.8

m)

from the triggering device

to

the nozzle.

f.

Hose protection - Steel braided hoses should be used on air operated fail safe systems

to keep the system from being activated by someone stepping on the hose or running

over it.

6.

Moleing

or

Flex lancing

a.

Control - The operator inserting the nozzle shall have direct control

of

the dump

system.

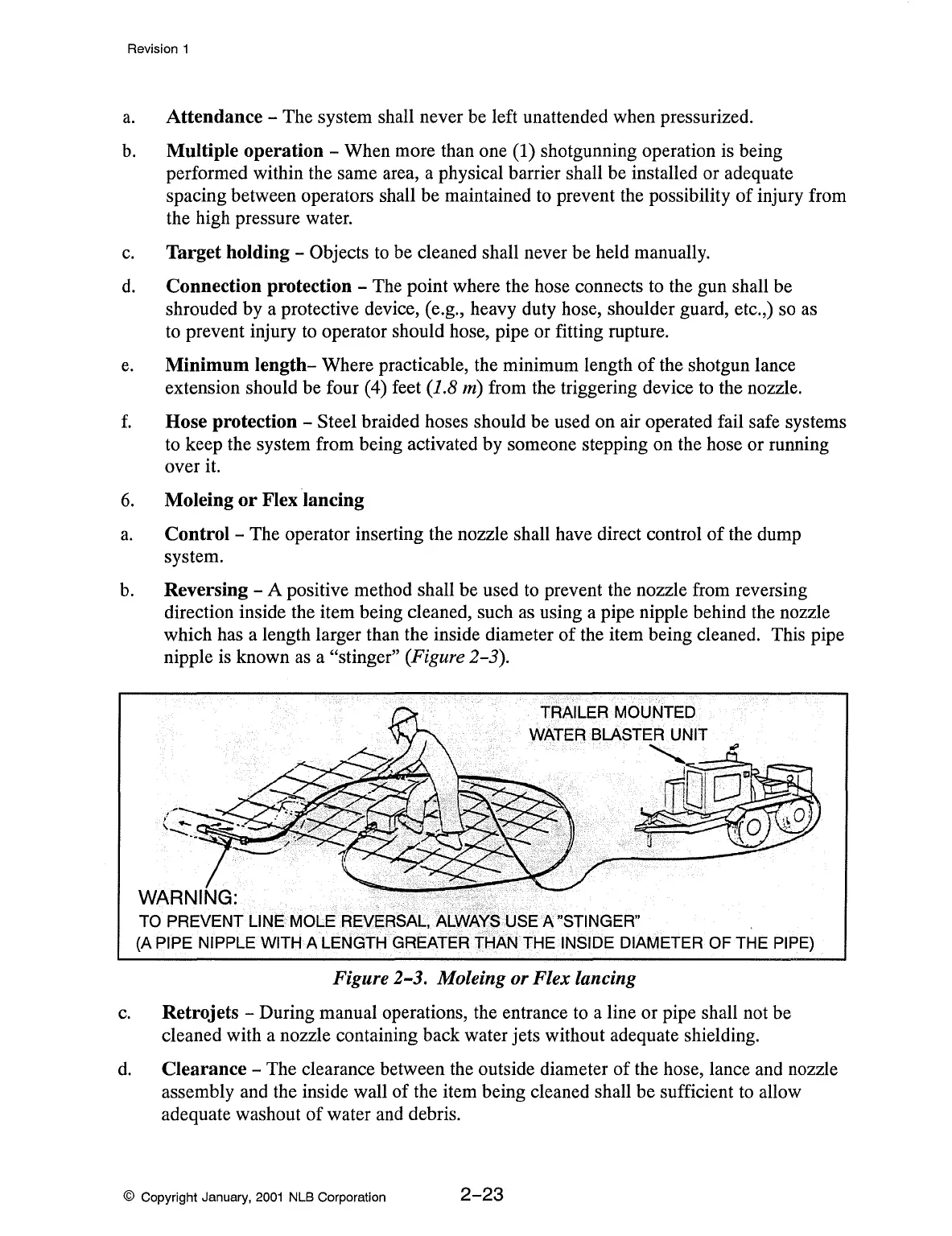

b.

Reversing - A positive method shall be used

to

prevent the nozzle from reversing

direction inside the item being cleaned, such as using a pipe nipple behind the nozzle

which has a length larger than the inside diameter

of

the item being cleaned. This pipe

nipple is known

as

a "stinger" (Figure 2-3).

TRAILER MOUNTED

TO

PREVENT LINE MOLE REVERSAL, ALWAYS USE A "STINGER"

(A PIPE NIPPLE WITH A LENGTH GREATER THAN THE INSIDE DIAMETER OF THE PIPE)

Figure

2-3.

Moleing

or

Flex

lancing

c.

Retrojets - During manual operations, the entrance to a line or pipe shall not be

cleaned with a nozzle containing back water jets without adequate shielding.

d.

Clearance - The clearance between the outside diameter of the hose, lance and nozzle

assembly and the inside wall of the item being cleaned shall be sufficient

to

allow

adequate washout

of

water and debris.

© Copyright January,

2001

NLB Corporation

2-23

Loading...

Loading...