30 Installation

2583703_EN_1608 Nortec GS

5.5.2 Best Practices for Installing Steam and Condensate Lines

Nortec recommends that you observe the following best practices for installing atmospheric steam lines

and condensate lines.

Steam Line

– Use rigid steam pipe made of copper (MED Type-L) or stainless steel (minimum DIN 1.4301) ex-

clusively. Steam pipes made of any other materials may adversely affect the operation of the unit,

and will void the warranty.

– Refer to Table 12 for the required minimum internal diameter of the steam pipe. The internal diameter

of the steam pipe can be expanded, but once expanded a reduction in diameter is not permitted,

except at the steam distributor.

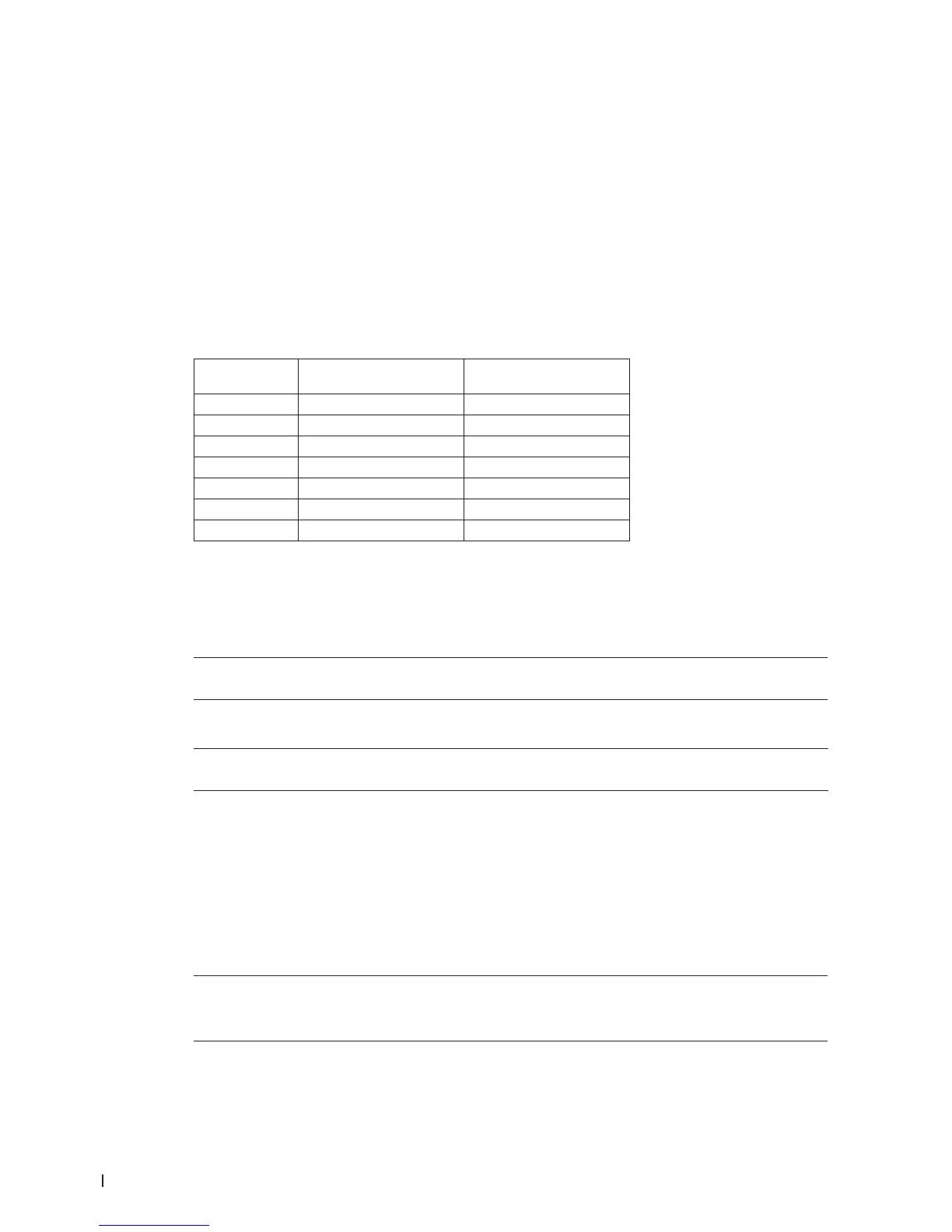

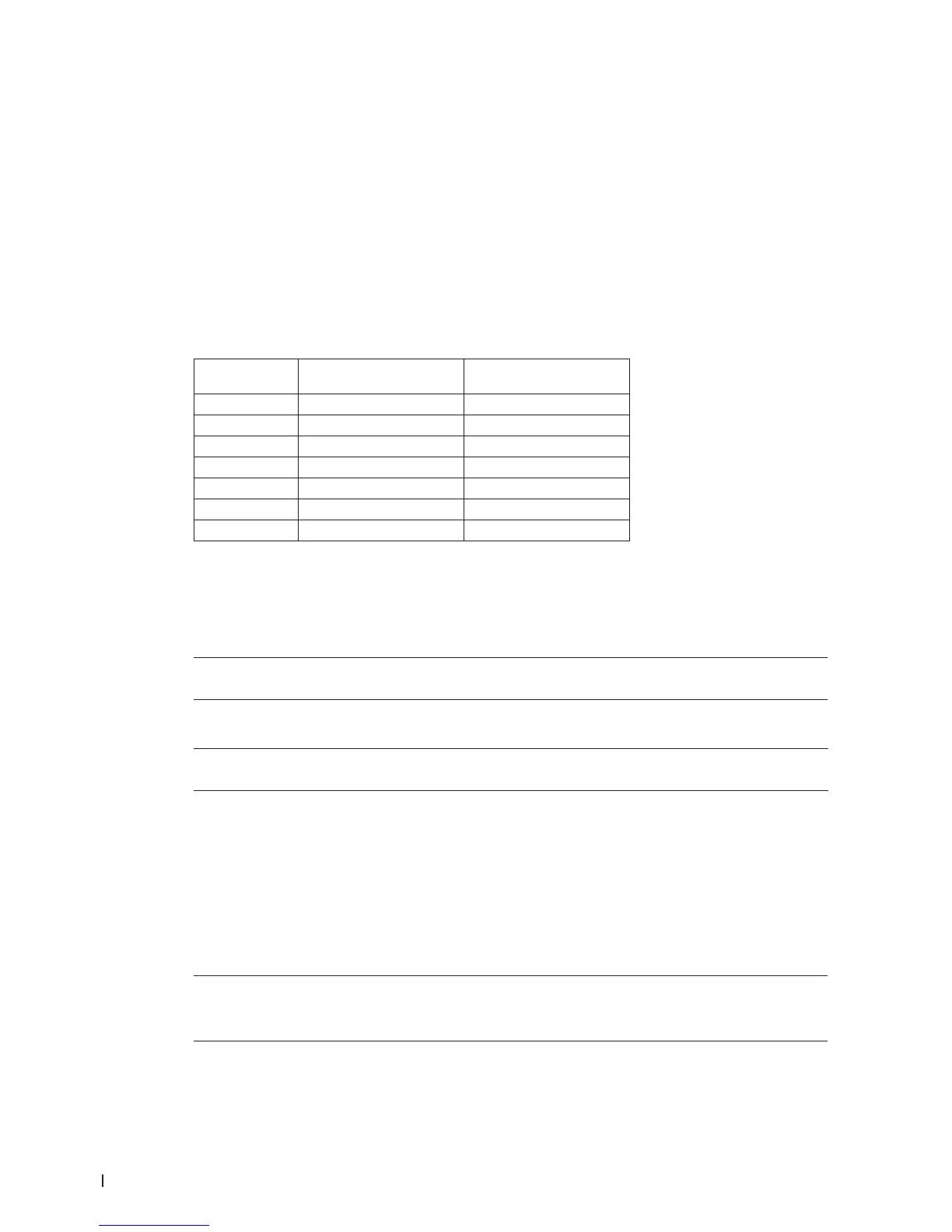

Table 12: Steam Pipe Diameter

Model Minimum Internal Diameter Maximum Equivalent

Steam Line Length

GS 50 1.75 in (45 mm) 45 ft (14 m)

GS 100 1.75 in (45 mm) 69 ft (21 m)

GS 150 3 in (76 mm) 100 ft (30 m)

GS 200 3 in (76 mm) 120 ft (37 m)

GS 300 3 in (76 mm) 150 ft (46 m)

GS 450 4 in (102 mm) 180 ft (55 m)

GS 600 4 in (102 mm) 260 ft (79 m)

– The length of the steam line should be kept as short as possible. It should not exceed the maximum

equivalent length shown in Table 12. Exceeding the maximum length can affect performance of the

unit, and may void the warranty. Backpressure in the line combined with duct static pressure must

not exceed 6 in H2O (1.49 kPa) for compact units, and 10 in H2O (2.49 kPa) for full-size units. Refer

also to Table 13 on page 31 for equivalent length of typical steam line ttings.

IMPORTANT! When calculating the backpressure on the unit, include allowance of approxi-

mately 0.12 in H2O for every foot (100 Pa for every meter) of steam line, and every 90° elbow.

– Use long radius elbows for steam pipes. This minimizes backpressure and formation of condensation.

IMPORTANT! When determining the length and routing of steam lines, allowances must also

be made for thermal expansion.

– The steam line from the humidier must lead straight upwards for a minimum of 12 in (300 mm),

before continuing on to the steam distribution system – refer to Figure 12 on page 29. The steam line

must have a minimum upslope of 10°, or a minimum downslope of 2° – refer to Figure 13 on page 31.

– Use only Nortec steam hose between the steam outlet on the humidier and the steam distributor.

Other types of steam hoses can affect performance of the unit, and may void the warranty. The

length of the steam hose must be kept to a minimum. The minimum bend radius of the steam hose

is 300 mm. The steam hose must not sag, and must have a minimum upslope of 10°, or a minimum

downslope of 2° to the steam distributor.

IMPORTANT! When calculating the backpressure on the unit, include allowance of approxi-

mately 0.12 in H2O for every foot (100 Pa for every meter) of steam hose.

Allowances must also be made for shrinkage in the length of the steam hose due to aging.

– Use short lengths of steam hose to connect the steam line to the humidier or steam distributor.

Secure the steam hoses with gear clamps.

Loading...

Loading...