12

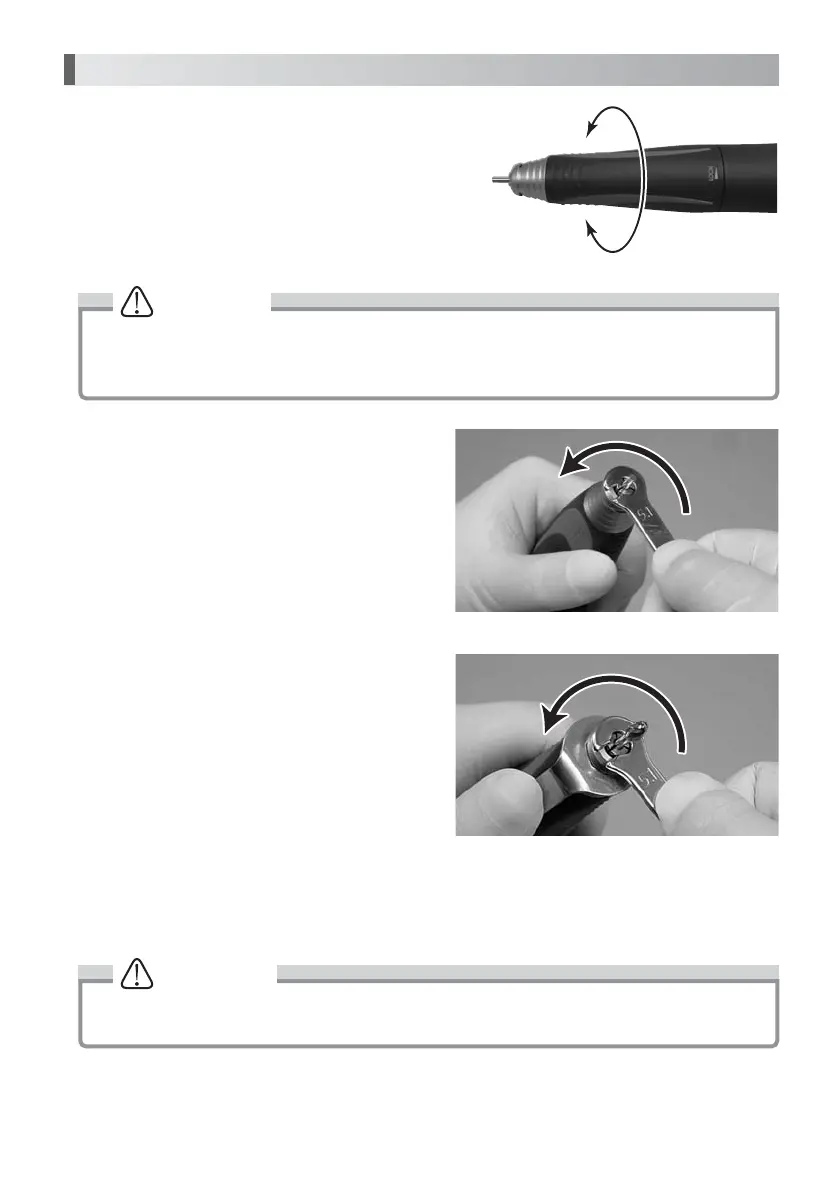

Fig.10

(1) Insertion or Removal of Bur

The chuck is opened by turning the Chuck Control

Ring to an open position. The chuck is loosened

and the bur can be removed. By turning the Chuck

Control Ring in the LOCK direction, the chuck is

closed and the bur can be mounted. At this time,

turn the ring until it clicks. (Fig. 9)

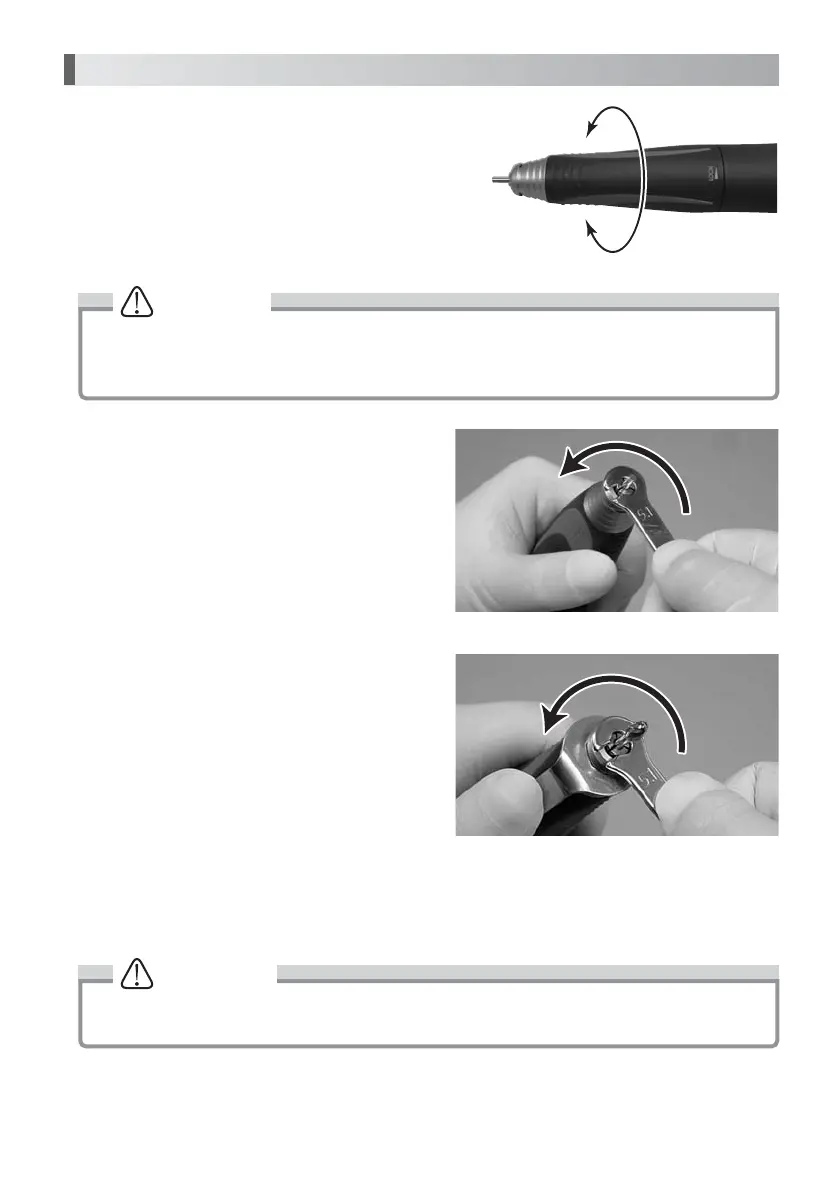

(2)

Cleaning and Replacement of Chuck

(1) Removal of Chuck

To remove the chuck, open the Chuck

Control Ring and turn the chuck

counterclockwise with the provided spanner

wrench. (Fig. 10)

* If a bur having a large diameter of a cutting

part is used under a high torque, the chuck

may rotate in the close direction and the bur

may be stuck and cannot be removed. In

this case, align the nose's slit and spindle's

spanner position (flat part), and apply an L

spanner to fix the spindle. Open the Chuck

Control Ring and turn the chuck

counterclockwise with the provided spanner

wrench to remove it. (Fig. 11)

(2) Cleaning of Chuck

To keep accuracy for the Chuck remove and clean the chuck as frequently as possible in the

ultrasonic cleaner. Clean at least once a week.

12. Handling of Motor and Handpiece

Fig.9

CAUTION

• Do not turn the Ring during motor rotation.

• Do not turn a motor, when it has not attached bur or the Ring Open position. It may be

reasons for the failure or overheating of the handpiece.

CAUTION

Neglecting to clean the chuck for a long time is very dangerous because wax, gypsum,

etc., accumulate in the chuck and the bur is caught insecurely, causing runout.

OPEN

LOCK

Loosen

Loosen

Fig.11

Loosen

Loosen

Loading...

Loading...