6-2XYAA6338

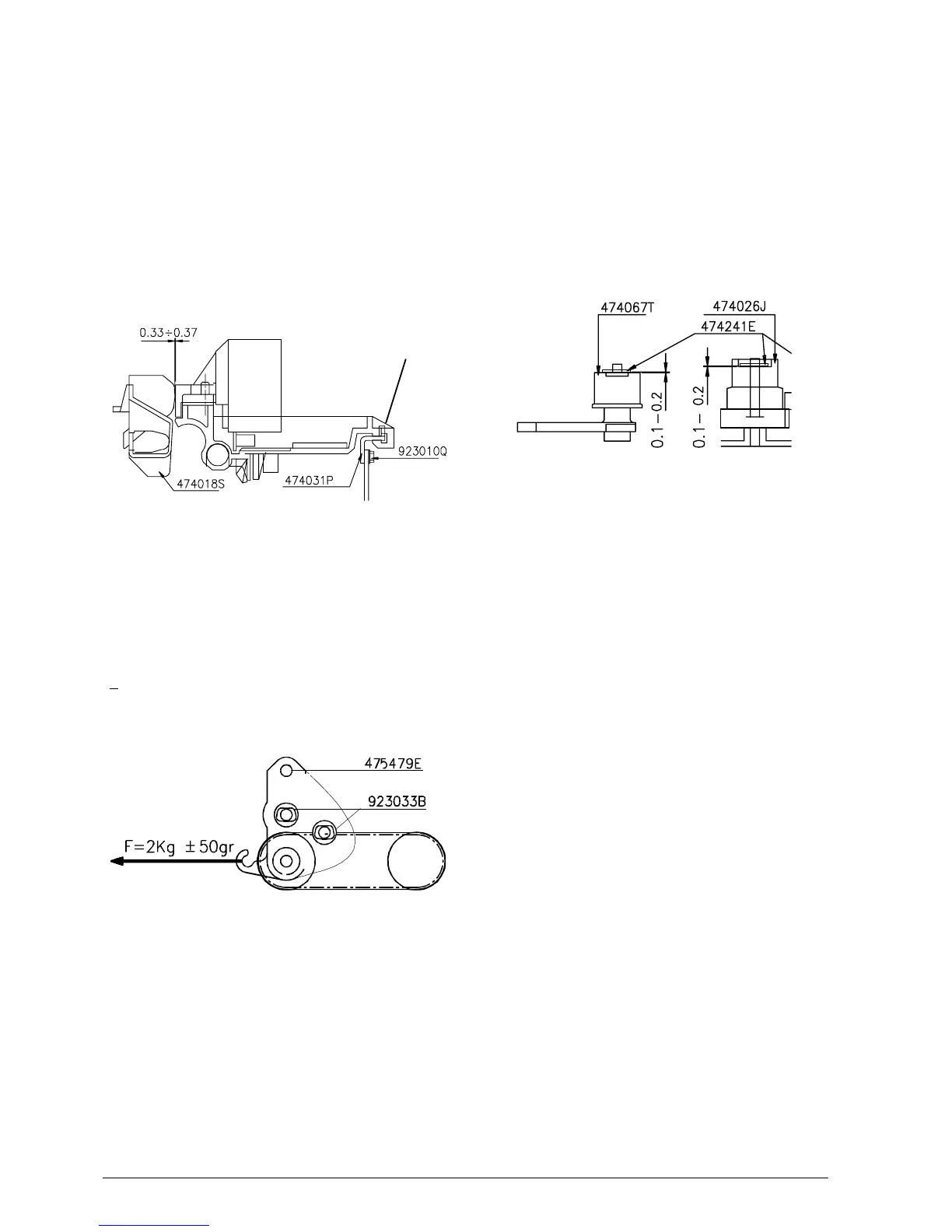

Fig. 6-2

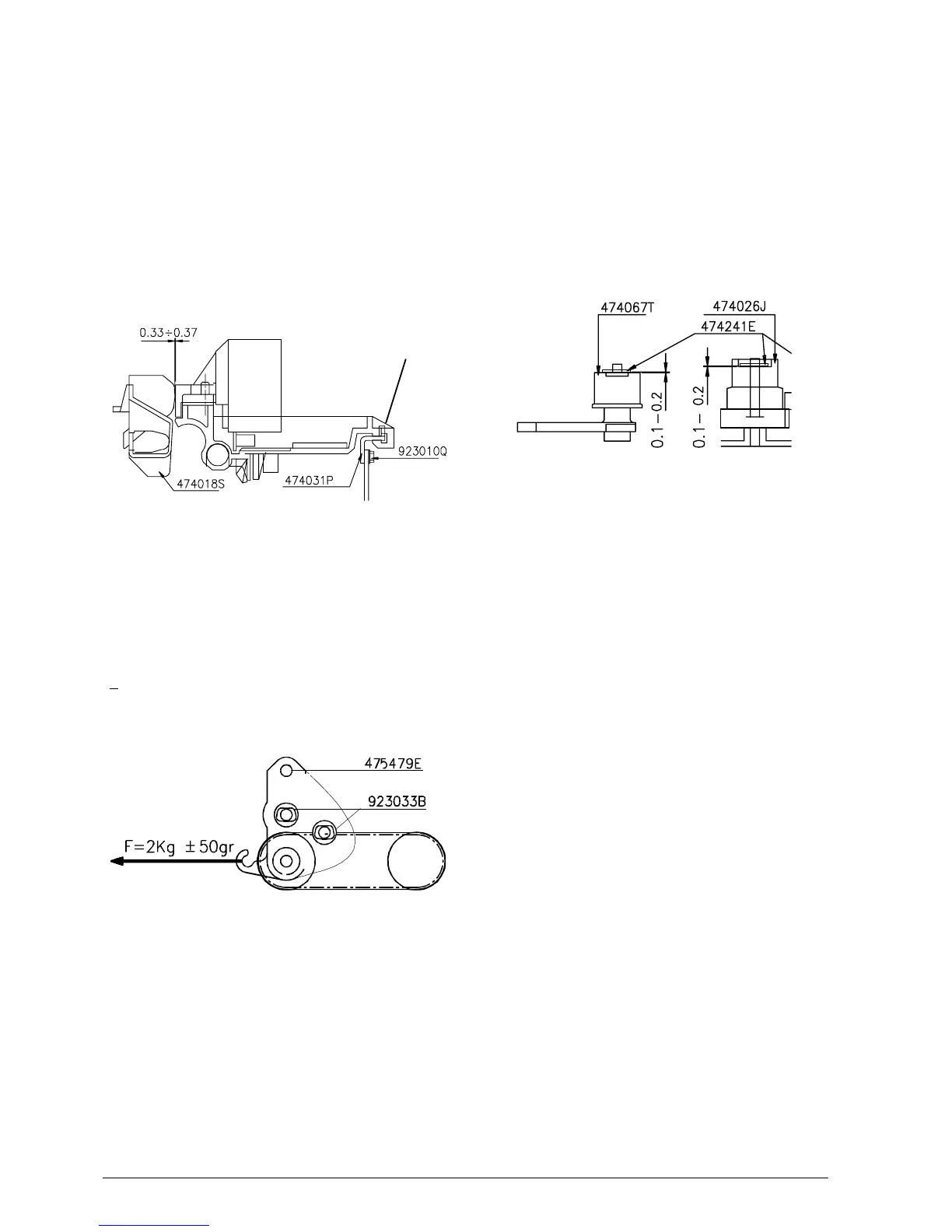

Fig. 6-3

Fig. 6-4

6.4 MOUNTING THE SNAP RINGS ON

THE CARRIAGE TRANSPORT

ASSEMBLY

During the assembly of codes 474067T, 474059B and

474026J, snap ring code 474241E must have a

clearance of 0.1 - 0.2 (Fig. 6-4). Clearance is obtained

by inserting a probe between the snap ring and the

stop point.

6.2 ADJUSTING THE PARALLELISM

AND PRINT HEAD-PLATEN

DISTANCE

By means of friction screws 923010Q, higher or lower

the plate code 474031P until obtaining the parallelism

between the print head and platen. Then check, using

a probe, for a clearance of 0.33 - 0.37 mm between

the needle profile and platen code 474018S (Fig 6-2).

Perform the adjustment procedure always maintaining

points A in contact with each other.

6.3 ADJUSTING THE TENSION OF THE

CARRIAGE TRANSPORT BELT

Pulling the end pulley support bracket with a

dynamometer in the direction of the arrow, tighten the

transport belt until reaching a value of 2 Kg

+ 50 gr. Using the screw code 923033B, block the

bracket code 475479E on the structure (Fig. 6-3).

A

Loading...

Loading...