DMTA-10043-01EN, Rev. C, July 2016

Application Notes

65

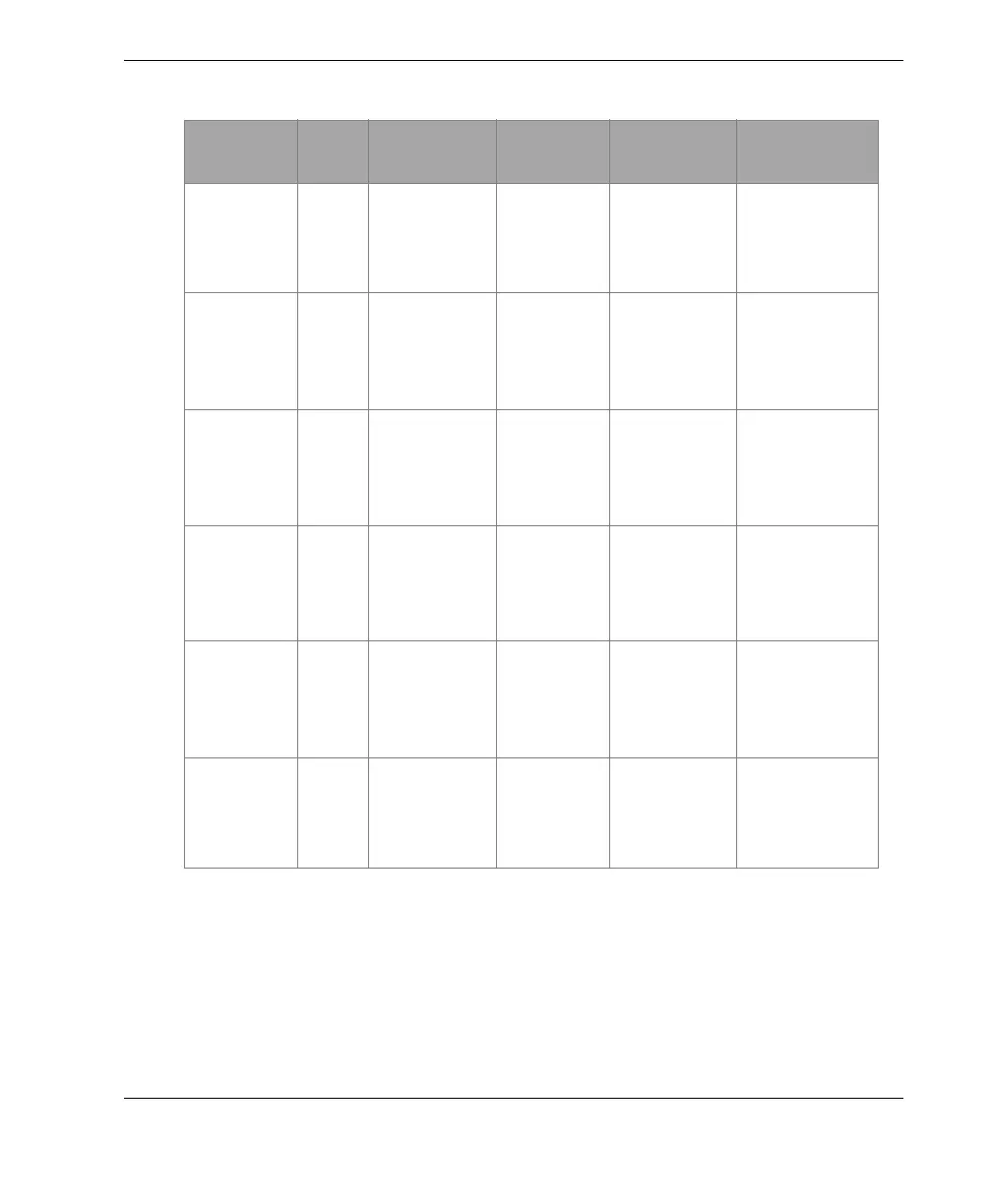

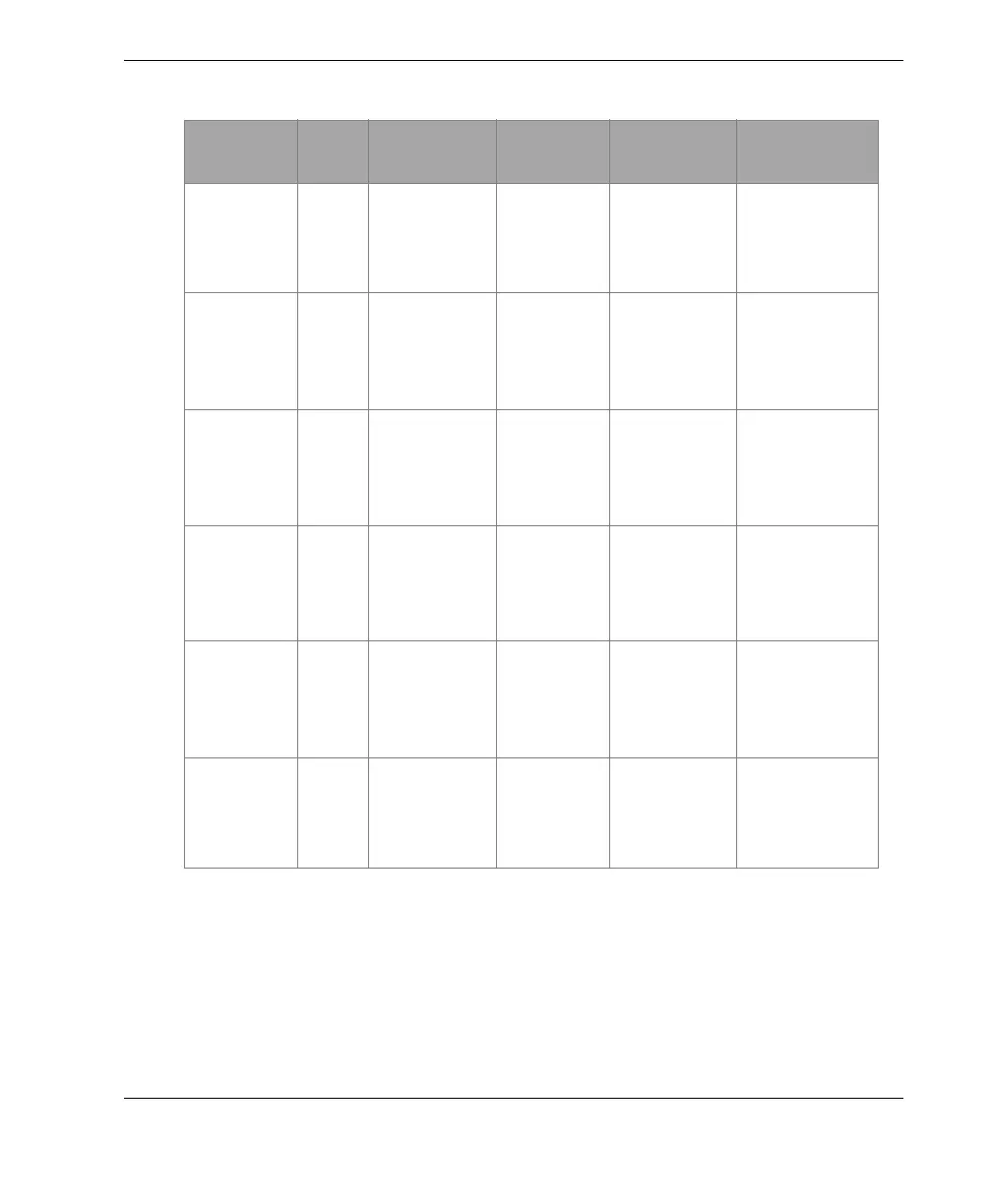

In selecting a transducer for a corrosion application it is also necessary to consider the

temperature of the material to be measured. Not all duals are designed for high

temperature measurements. The chart above lists recommended temperature ranges

for the duals used with the 27MG Ultrasonic Thickness Gage. For other transducers,

consult the manufacturer. Using a transducer on materials whose temperature is

beyond the specified range can damage or destroy the transducer.

D794 5.0 Straight 7.2 mm

(0.283 in.)

0.75 mm to

50 mm

(0.030 in. to

2in.)

0°C to 50°C

(32 °F to

122 °F)

D797

D797-SM

2.0 Right angle

Straight

22.9 mm

(0.900 in.)

3.8 mm to

635 mm

(0.150 in. to

25 in.)

−20 °C to

400 °C

(−5°F to

752 °F)

D7226

D798-LF

7.5 Right angle 8.9 mm

(0.350 in.)

0.71 mm to

50 mm

(0.028 in. to

2in.)

−20 °C to

150 °C

(−5°F to

300 °F)

D798

D798-SM

7.5 Right angle

Straight

7.2 mm

(0.283 in.)

0.71 mm to

50 mm

(0.028 in. to

2in.)

−20 °C to

150 °C

(−5°F to

300 °F)

D799 5.0 Right angle 11.0 mm

(0.434 in.)

1 mm to

500 mm

(0.040 in. to

20 in.)

−20 °C to

150 °C

(−5°F to

300 °F)

MTD705 5.0 Right angle 5.1 mm

(0.200 in.)

1.0 mm to

19 mm

(0.040 in. to

0.75 in.)

0°C to 50°C

(32 °F to

122 °F)

Table 6 Transducer selection (continued)

Probe MHz Connector

Tip

diameter

Range

(steel)

Temperature

range

Loading...

Loading...