135

Appendix

the voltage tap can be used for measuring the power factor and capacitance of

C1 and C2 insulation of the bushing. In addition, this tap can be used for

monitoring the partial discharge during factory tests and insulation leakage

current (including partial discharge) during field service operation.

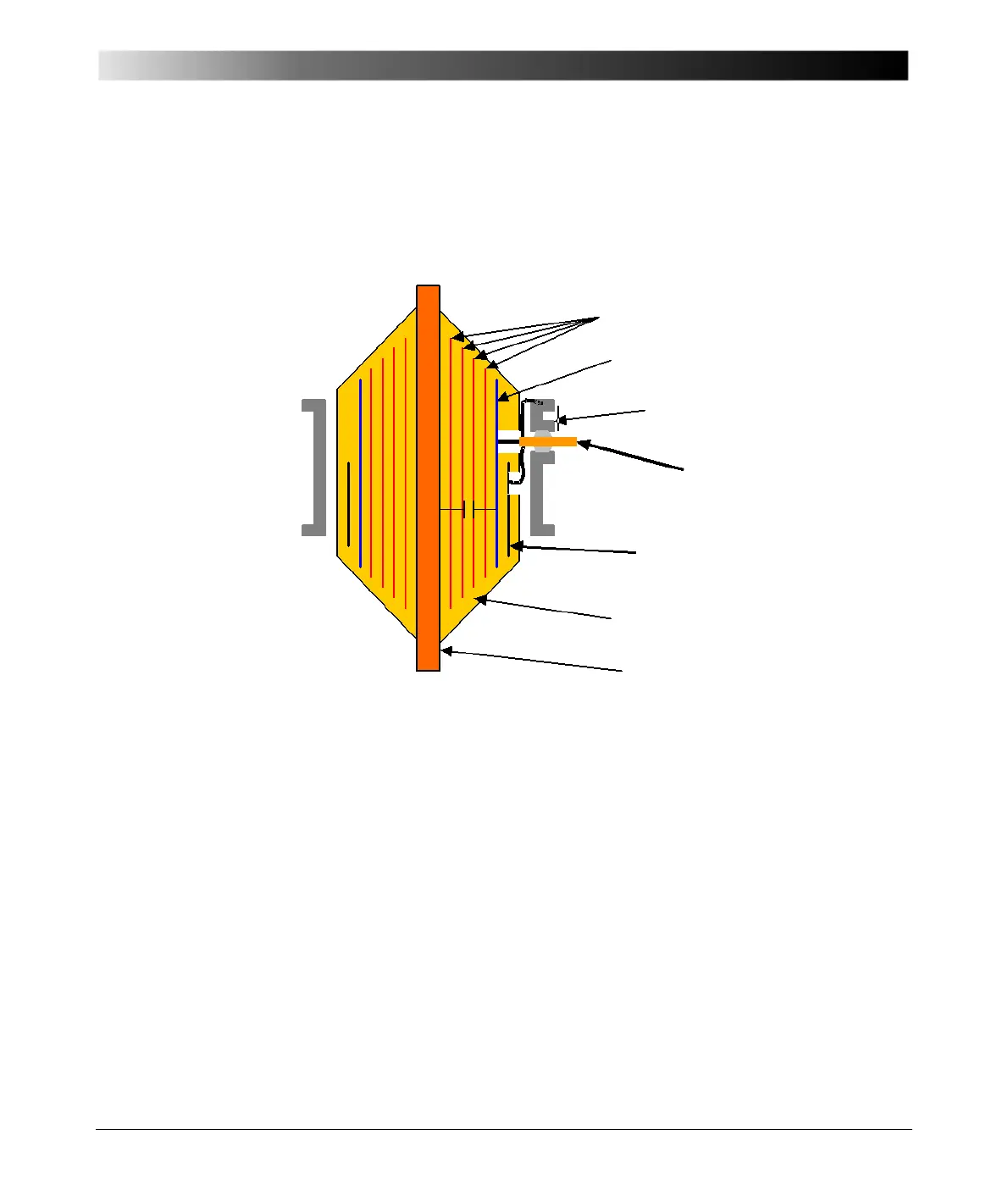

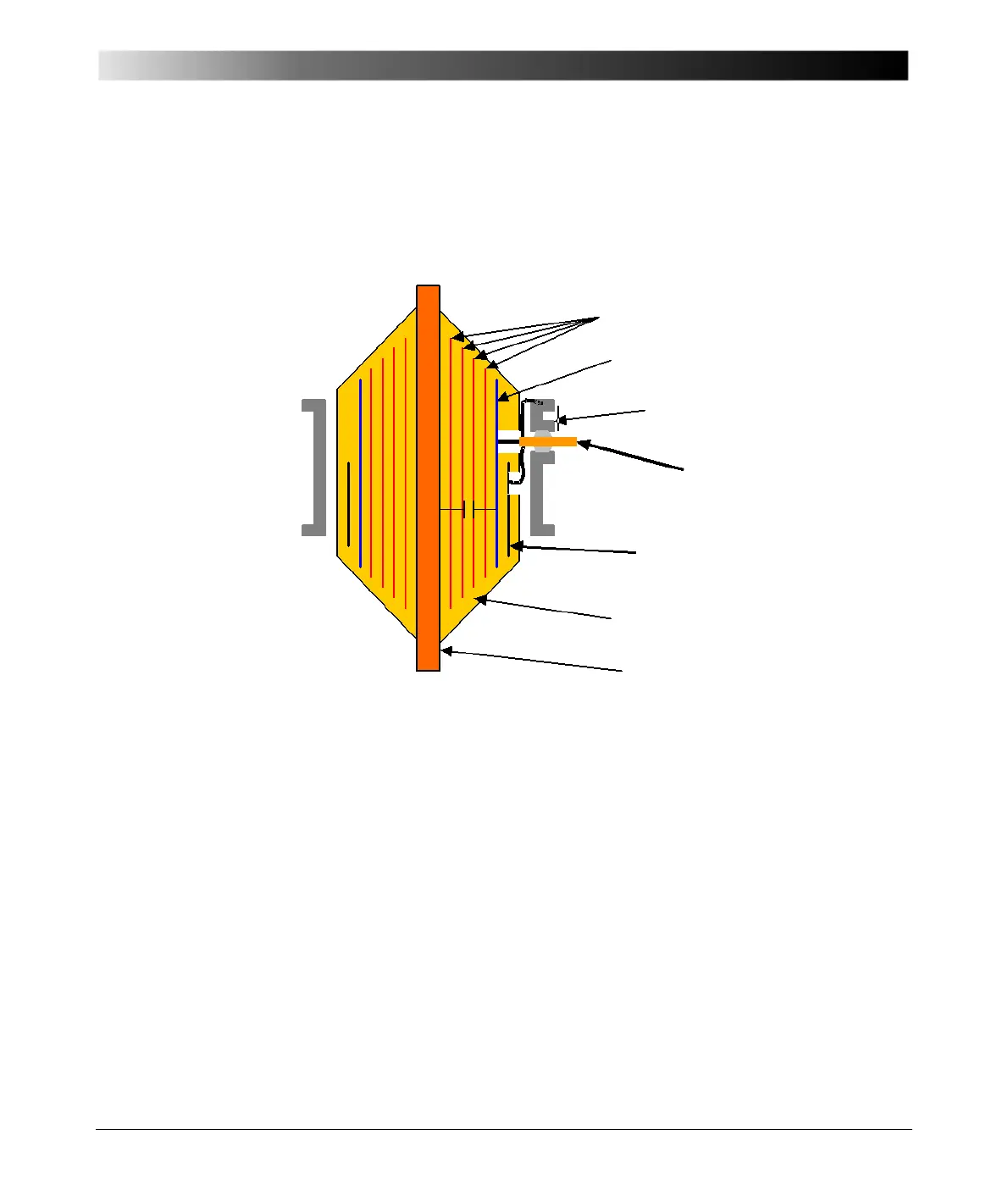

See Figure 12-2 for condenser design and voltage tap details.

Figure 12-2 Design/construction details of a typical condenser bushing

rated 115 kV and above

Condenser bushings rated 69 kV and below as per the IEEE Standards are

provided with C1 capacitance, which is the main capacitance. This capacitance

is formed by the oil/paper insulation between the central conductor and the C1

layer/foil, which is inserted during the condenser winding process. The C1 layer/

foil is internally connected to the test tap.

These bushings have an inherent C2 capacitance, which is formed by the

insulation between the C1 layer and the mounting flange. This insulation

consists of a few layers of paper with adhesive, an oil gap between the

condenser core and the mounting flange, and the tap insulator. Under normal

operating condition, the C1 layer/foil is automatically grounded to the mounting

flange with the help of the screw-in test tap cover that makes a connection

between the test tap spring and the flange. The C2 insulation under normal

operating condition is therefore shorted and not subjected to any voltage stress.

The test tap is used for measuring the power factor and capacitance of C1 and

Voltage Equalizers

C1 Layer/Foil

Mounting Flange

Voltage Tap Stud

C

2

Layer/Foil

(always grounded)

Oil Impregnated Paper

Central Conductor

C1

C2

Loading...

Loading...