CP TD1 Reference Manual V 1.44

136

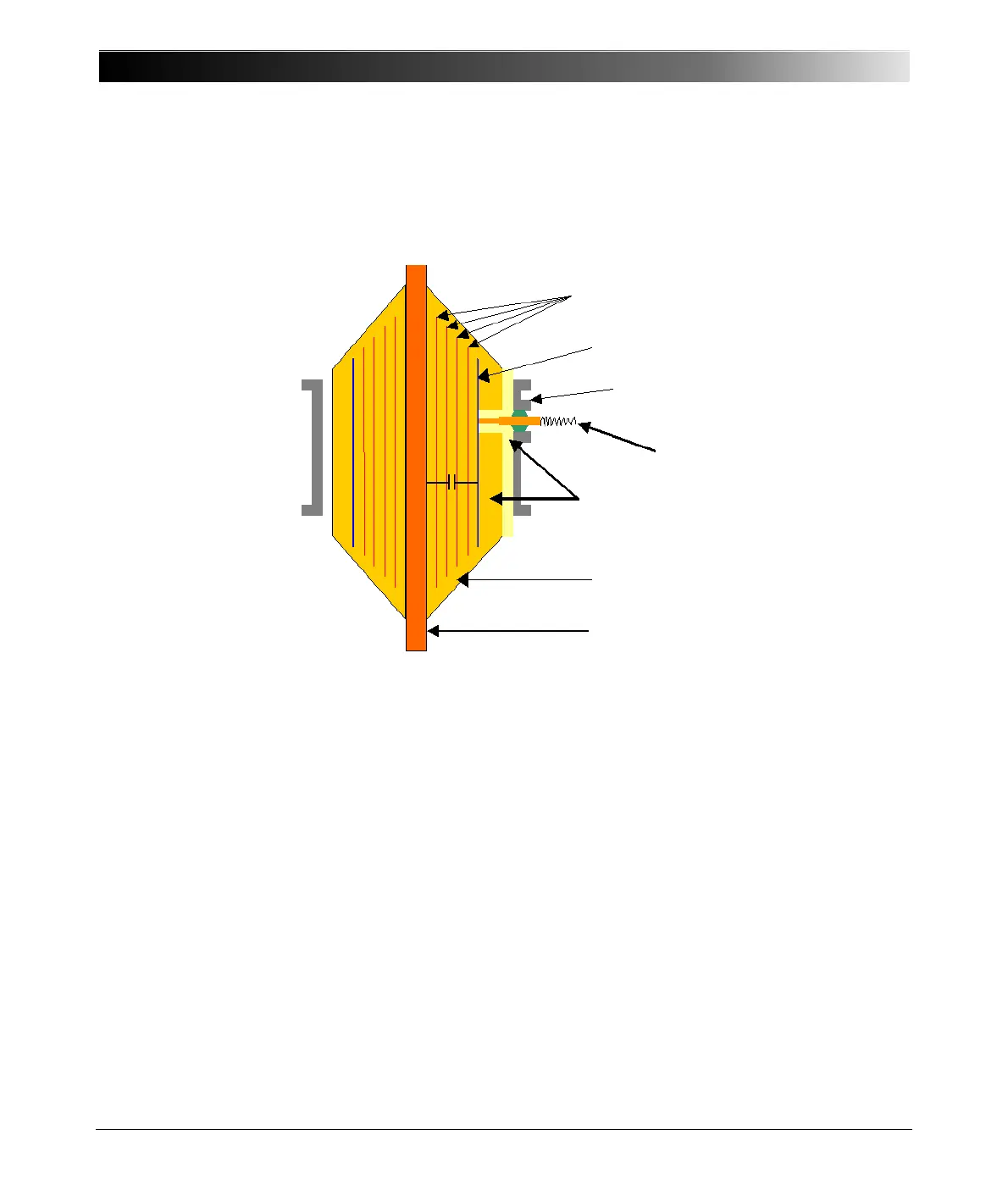

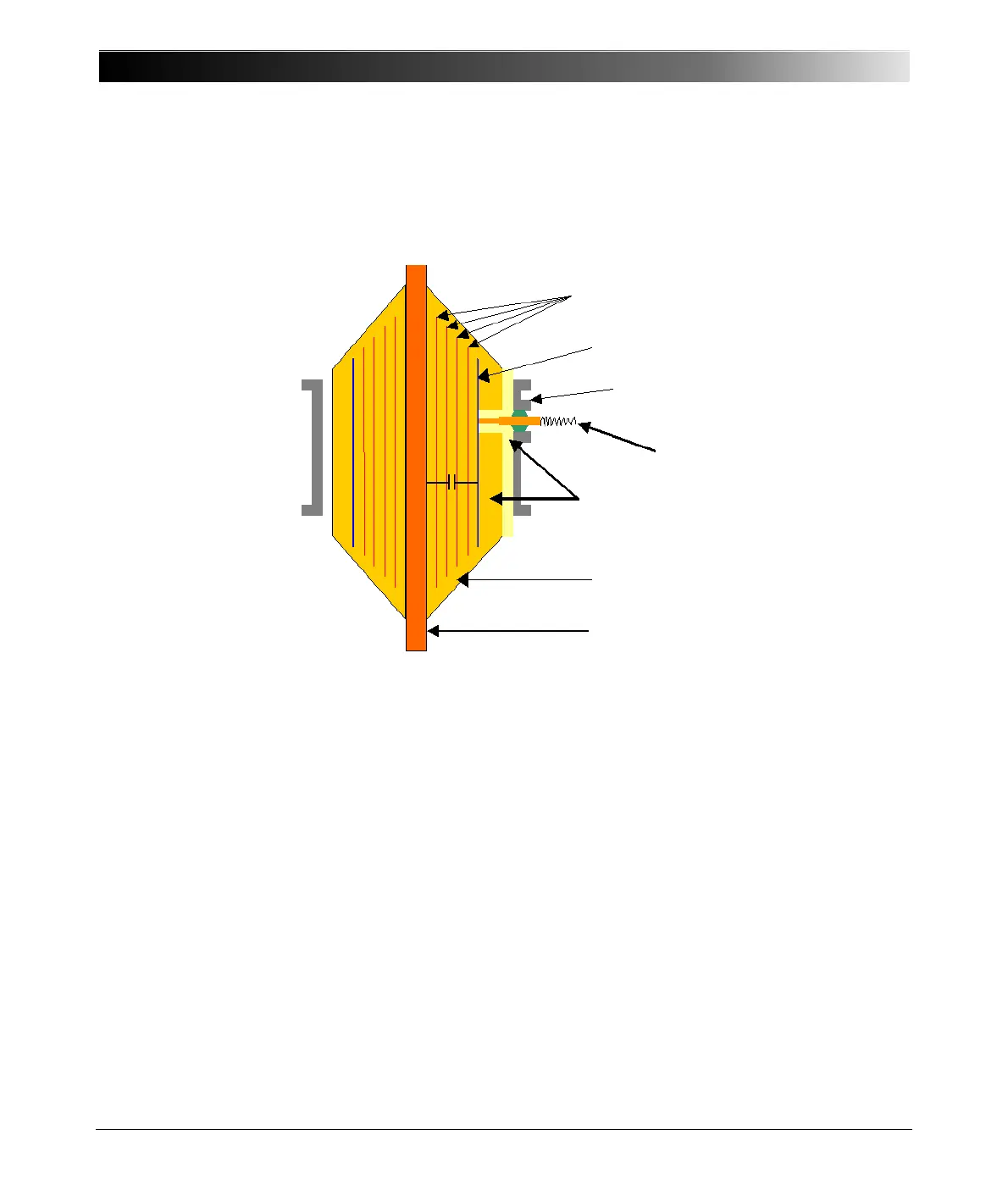

C2 insulation of the bushing. In addition, this tap is sometimes used for

monitoring the partial discharge during factory tests and insulation leakage

current (including partial discharge) during field service operation.

See Figure 12-3 for condenser design and test tap details.

Figure 12-3 Design/construction details of a typical condenser bushing

rated 69 kV and below

12.5.4 Factors Affecting C1, C2 Capacitance and Power Factor

Measurements

As mentioned earlier, the C1 and C2 capacitance of condenser bushings rated

115 kV and above are strictly controlled by design and are mainly dependent

upon oil impregnated, paper insulation. Therefore, the power factor and

capacitance test values under normal circumstances, are not affected too much

by external factors. However, under conditions of contamination and high

humidity, these measurements may be significantly affected. In addition,

capacitively coupled resistive paths to ground may affect these measurements.

These may include supporting structures, wooden crates that are moist/wet,

resistance between bushing mounting flange and the transformer tank, stray

effect from other objects, and external connections during testing. Although, the

Voltage Equalizers

C1 Layer/Foil

Mounting Flange

Oil Impregnated Paper

Central Conductor

Test Tap Spring

Bushing oil/paper in C2 insulation

C1

C2

Loading...

Loading...