CP TD1 Reference Manual V 1.44

96

7.4 Capacitance and DF Measurement on High-Voltage

Bushings

The dissipation factor test is the most effective known field test procedure for the

early detection of bushing contamination and deterioration. It also measures

alternating (AC) test current, which is directly proportional to bushing

capacitance.

Bushing dissipation factor and capacitance should be measured when a bushing

is first installed and also one year after installation. After these initial

measurements, bushing power or dissipation factor and capacitance should be

measured at regular intervals (3 to 5 years typically). The measured values

should be compared with previous tests and nameplate values.

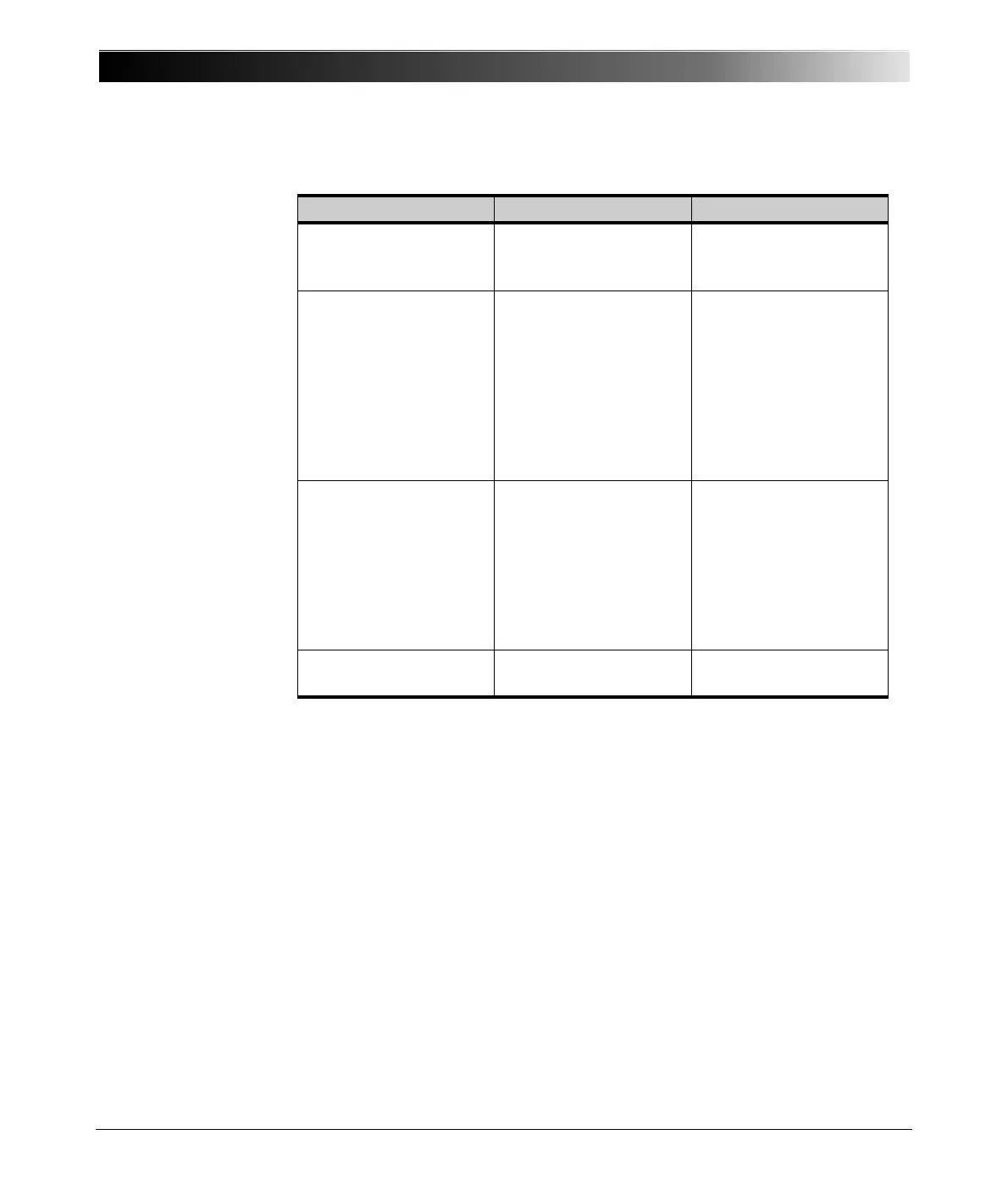

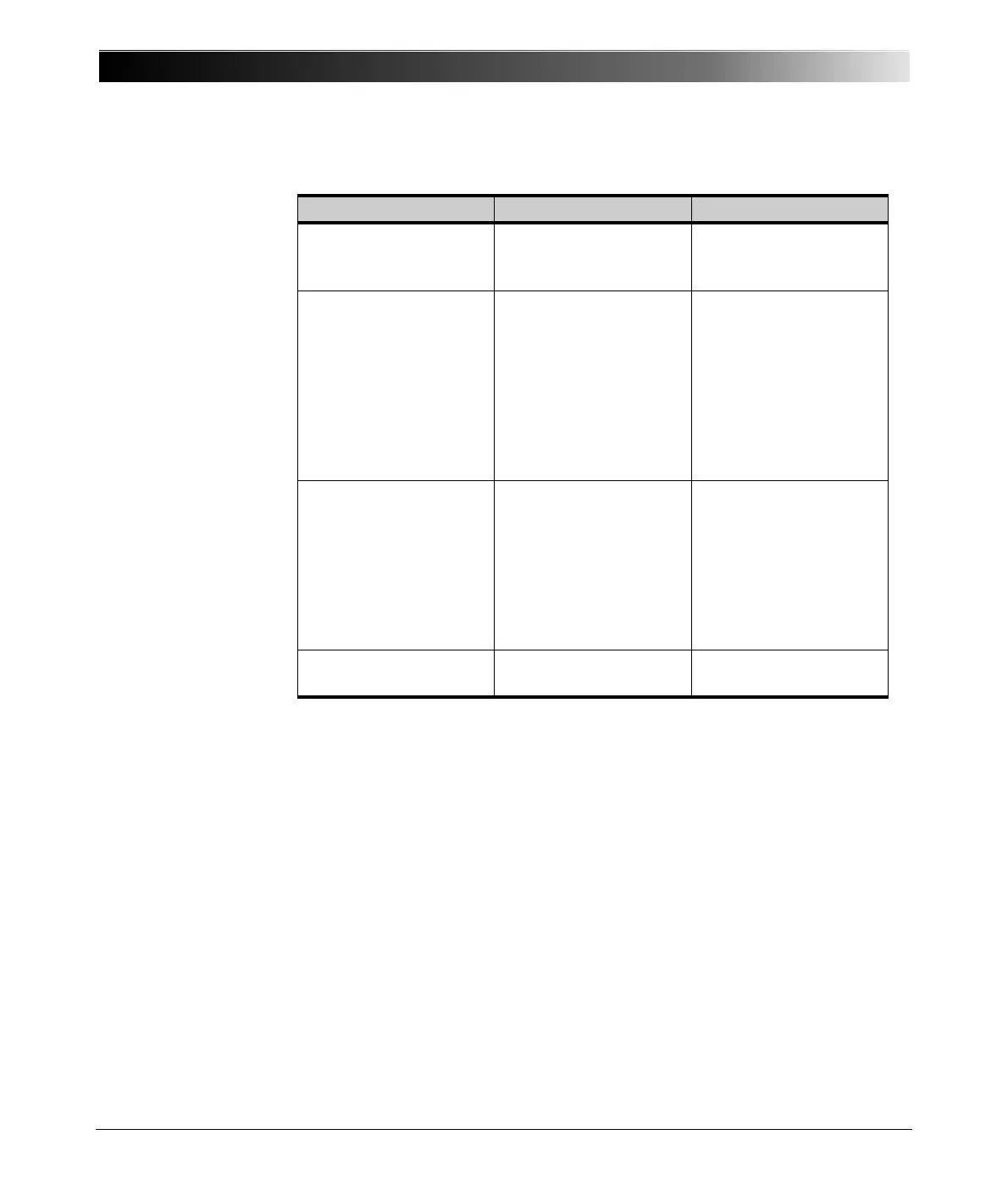

Lightning Cracked or broken

porcelain;

Complete failure

Visual inspection;

Test lightning arresters

Corona Internal breakdown;

Radio interference;

Treeing along surface of

paper or internal

surfaces

Power factor test;

Hot-collar test;

Hot wire test;

Radio-influence voltage

(RIV) test;

Thermographic

scanning;

Dissolved gas-in-oil

analysis (DGA)

Short-circuited

condenser sections

Increased capacitance;

Reduced voltage at

capacitance tap terminal;

Adds internal stress to

insulation

Power factor test;

Voltage test at

capacitance tap;

Capacitance test;

Thermographic

scanning;

Dissolved gas-in-oil

analysis (DGA)

Darkened oil Radio interference;

Poor test results

Power factor test;

Hot-collar test

Table 7-1 Bushing faults, part 1 [4.3]

Failure Possible results Methods of detection

Loading...

Loading...