155

Appendix

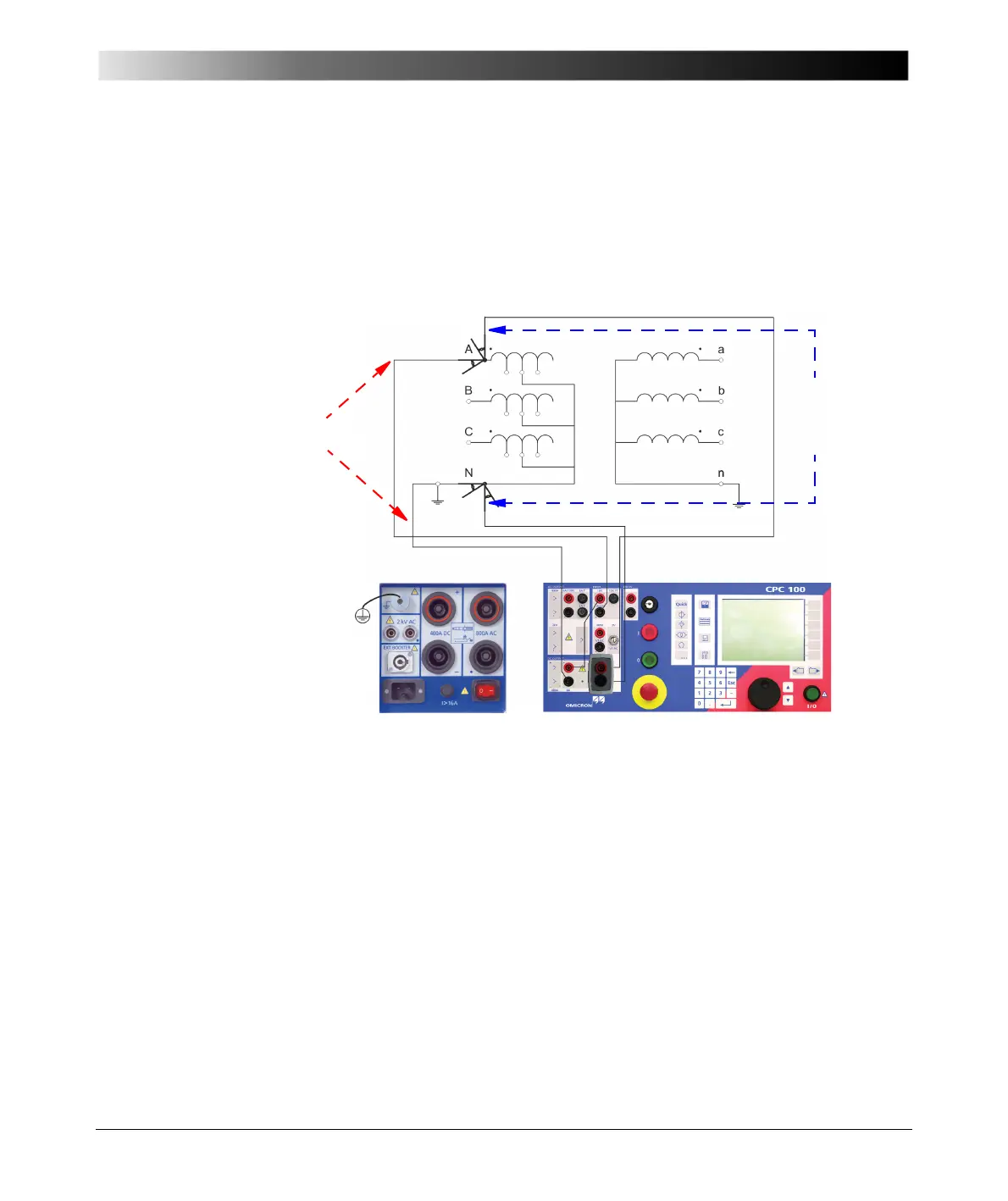

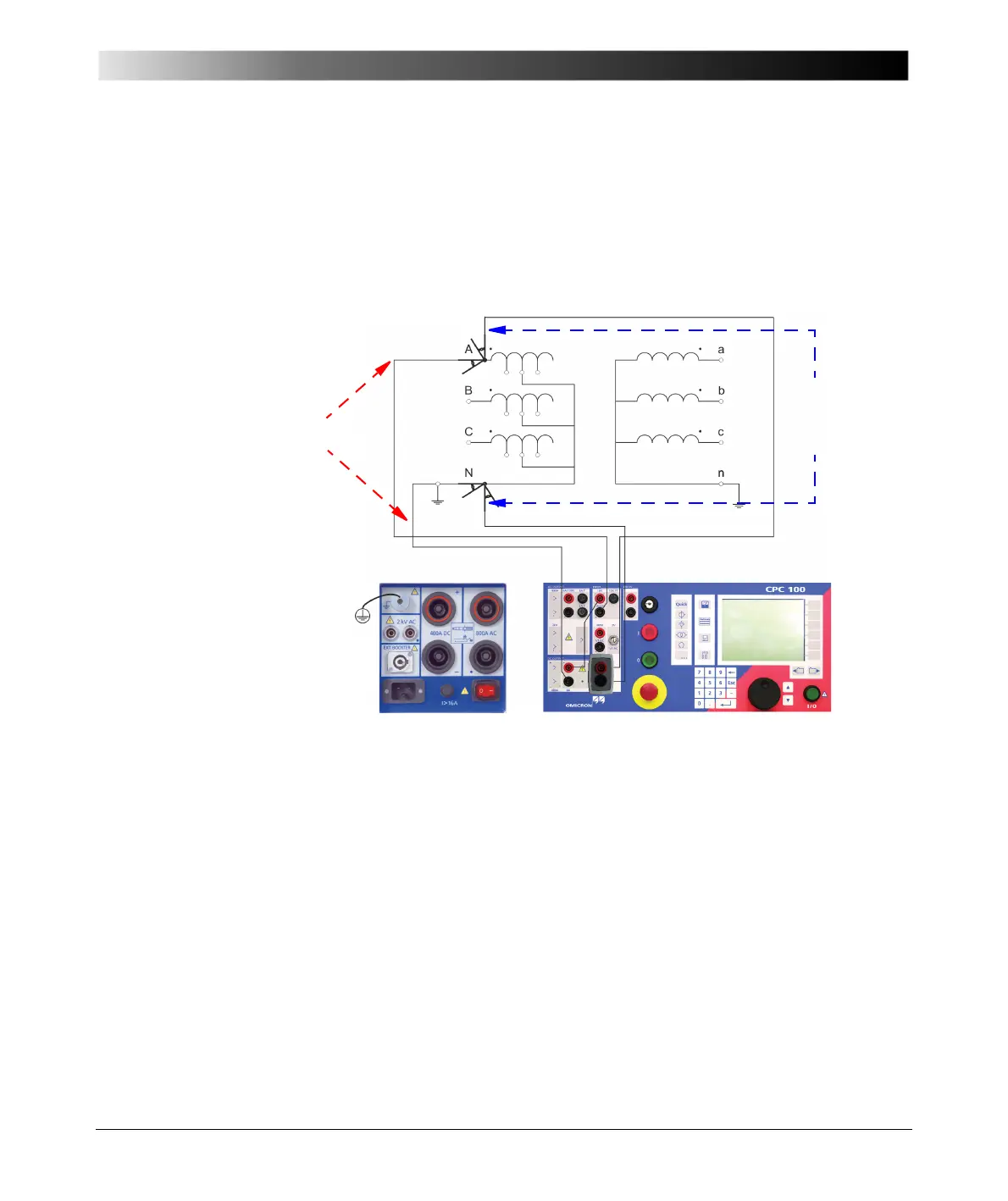

12.9.5 Four-Wire Connection for Transformer Winding Resistance

Measurement

Since the winding resistances are very small, the test set is connected in 4-wire

configuration. It has to be observed that the contact resistances of the

connection clamps do not falsify the measuring result (Figure 12-13).

Figure 12-13 Four-wire resistance measurement

A constant current source is used to feed a direct current into the winding. The

test current should be at least 1% of the rated current to bring the core into

saturation. On the other hand it should not exceed 15% of the rated current to

avoid temperature rise during measurement. A relatively high no-load voltage

enables a quick saturation of the core and a final value with only minor

fluctuations is reached. Therefore, in most cases the charging time per tap is

distinctly less than 30 seconds. By pressing one button on the test system, all

values are logged and a test report is automatically generated (Figure 12-14).

The resistance values are automatically corrected to the reference temperature

by automatic calculation utilizing the following formula:

Measuring

lines for I

Measuring

lines for U

Loading...

Loading...