69

Power Transformers

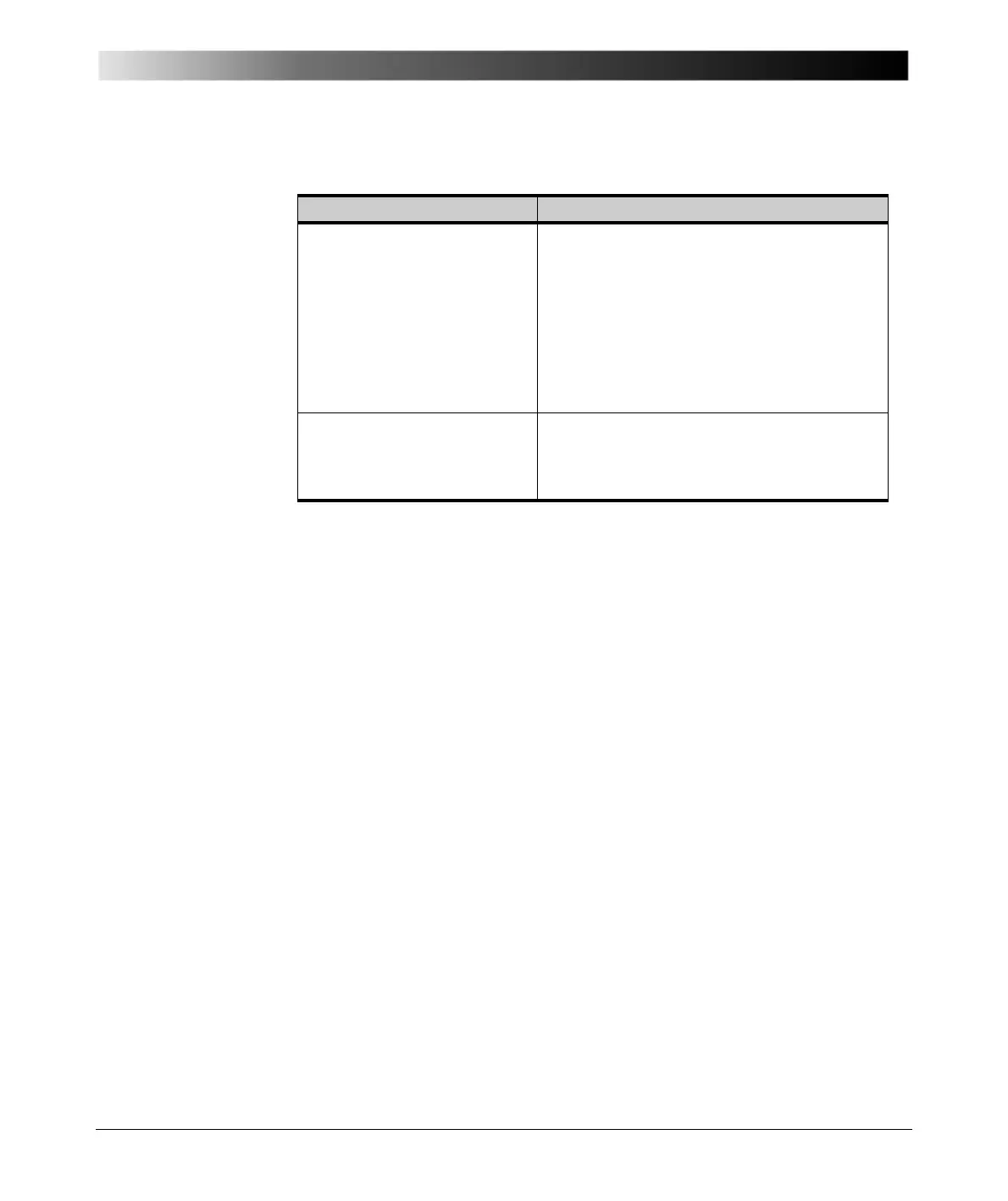

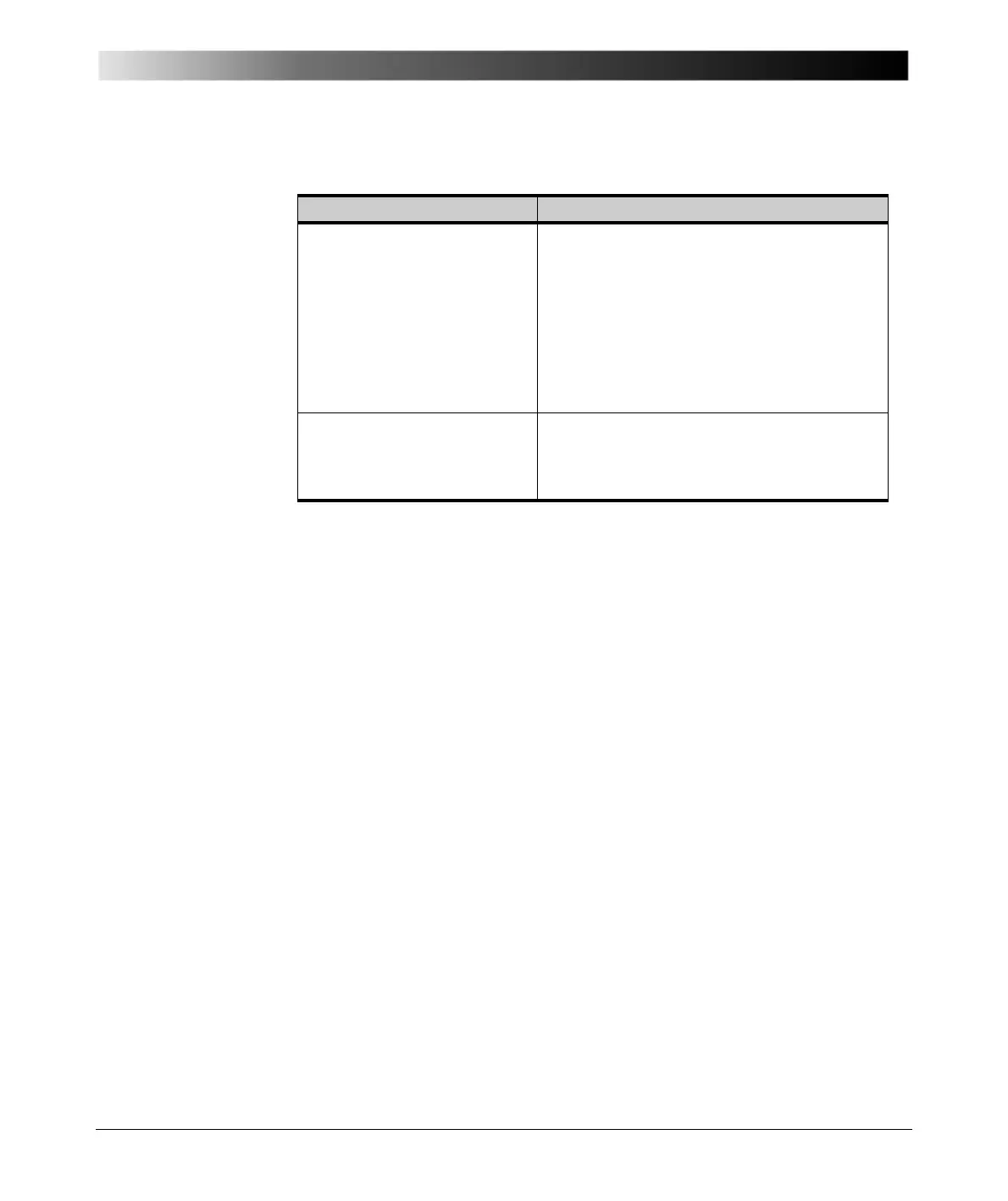

Notes on Table :

1. X wax formation comes from paraffinic oils (paraffin based). These are not

used in transformers at present in the United States but are predominate in

Europe.

2. The last overheating problem in the table says "over 700°C". Recent

laboratory discoveries have found that acetyl can be produced in trace

amounts of 500°C, which is not reflected in this table. We have several

transformers that show trace amounts of acetylene that are probably not

active arcing but are the result of high-temperature thermal faults as in the

example. It may also be the result of one arc, due to a nearby lightning strike

or voltage surge.

3. A bad connection at the bottom of a bushing can be confirmed by comparing

infrared scans of the top of a bushing with a sister bushing. When loaded,

heat from a poor connection at the bottom will migrate to the top of the

bushing, which will display a markedly higher temperature. If the top

connection is checked and found tight, the problem is probably a bad

connection at the bottom of the bushing.

Overheating 300°C - 700°C Defective contacts at bolted connections

(especially busbar), contacts with tap

changer, connections between cable and

draw-rod of bushings. Circulating currents

between yoke clamps and bolts, clamps and

laminations, in ground wiring, bad welds or

clamps in magnetic shields. Abraded

insulation between adjacent parallel

conductors in windings.

Overheating over 700°C Large circulating currents in tank and core.

Minor currents in tank walls created by high

uncompensated magnetic field. Shorted core

laminations.

Table 6-3 Transformer Faults [3.3]

Fault Examples

Loading...

Loading...