Standards Compliance

5

5.3 UL Standards

SIEPYEUOQ2A01A AC Drive Q2A Technical Manual 197

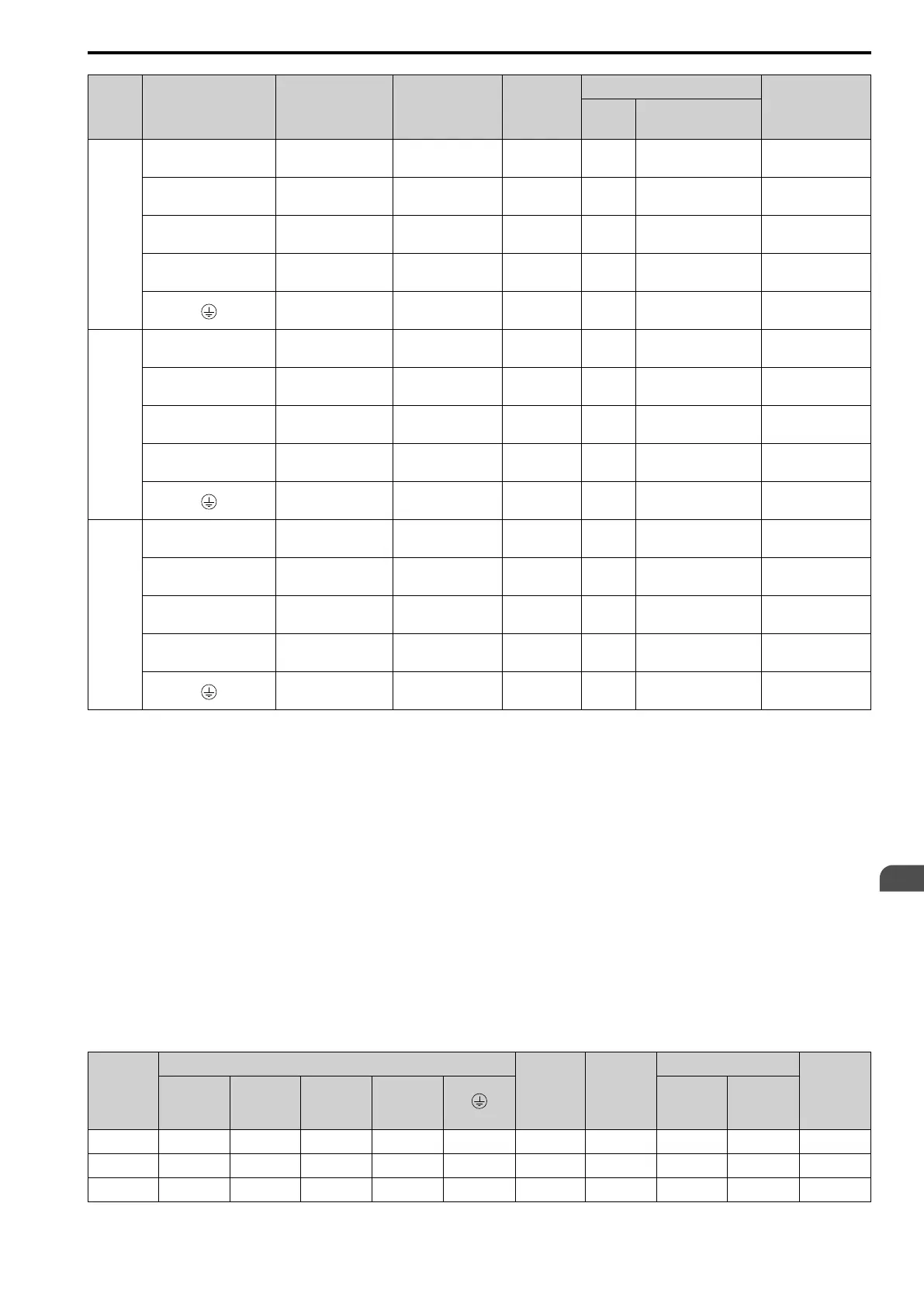

Model Terminals

Recommended

Gauge

AWG, kcmil

Applicable Gauge

(IP20 Applicable

Gauge

*1

)

AWG, kcmil

Wire

Stripping

Length

*2

mm

Terminal Screw

Tightening Torque

N∙m (lb∙in.)

Size Shape

4453

R/L1, S/L2, T/L3, R1/L11,

S1/L21, T1/L31

250 × 4P

2/0 - 300 × 4P

(250 - 300 × 4P)

- M12 Hex self-locking nut

35

(310)

U/T1, V/T2, W/T3 4/0 × 4P

2/0 - 300 × 4P

(250 - 300 × 4P)

- M12 Hex self-locking nut

35

(310)

-, +1 4/0 × 4P

3/0 - 400 × 4P

(300 - 400 × 4P)

- M12 Hex self-locking nut

35

(310)

+3 3/0 × 4P

2 - 4/0

(4/0 × 4P)

- M12 Hex self-locking nut

35

(310)

1/0

1/0 - 300

(-)

- M12 Hex bolt (slotted)

32 - 40

(283 - 354)

4568

R/L1, S/L2, T/L3, R1/L11,

S1/L21, T1/L31

250 × 4P

2/0 - 300 × 4P

(250 - 300 × 4P)

- M12 Hex self-locking nut

35

(310)

U/T1, V/T2, W/T3 4/0 × 4P

2/0 - 300 × 4P

(250 - 300 × 4P)

- M12 Hex self-locking nut

35

(310)

-, +1 300 × 4P

3/0 - 400 × 4P

(300 - 400 × 4P)

- M12 Hex self-locking nut

35

(310)

+3 3/0 × 4P

2 - 4/0 × 4P

(4/0 × 4P)

- M12 Hex self-locking nut

35

(310)

2/0

2/0 - 300

(-)

- M12 Hex bolt (slotted)

32 - 40

(283 - 354)

4675

R/L1, S/L2, T/L3, R1/L11,

S1/L21, T1/L31

300 × 4P

2/0 - 300 × 4P

(250 - 300 × 4P)

- M12 Hex self-locking nut

35

(310)

U/T1, V/T2, W/T3 300 × 4P

2/0 - 300 × 4P

(250 - 300 × 4P)

- M12 Hex self-locking nut

35

(310)

-, +1 400 × 4P

3/0 - 400 × 4P

(300 - 400 × 4P)

- M12 Hex self-locking nut

35

(310)

+3 4/0 × 4P

2 - 4/0 × 4P

(4/0 × 4P)

- M12 Hex self-locking nut

35

(310)

2/0

2/0 - 300

(-)

- M12 Hex bolt (slotted)

32 - 40

(283 - 354)

*1 For IP20 protection, use wires that are in the range of applicable gauges.

*2 Remove insulation from the ends of wires to expose the length of wire shown.

*3 For wire gauges more than AWG 8, tighten to a tightening torque of 4.1 N∙m to 4.5 N∙m (36 lb∙in. to 40 lb∙in.).

*4 Terminals - and +1 have two screws. The Recommended Gauge is the wire gauge for one terminal.

*5 A junction terminal is necessary to connect a braking resistor unit (LKEB-series) to terminals B1 and B2.

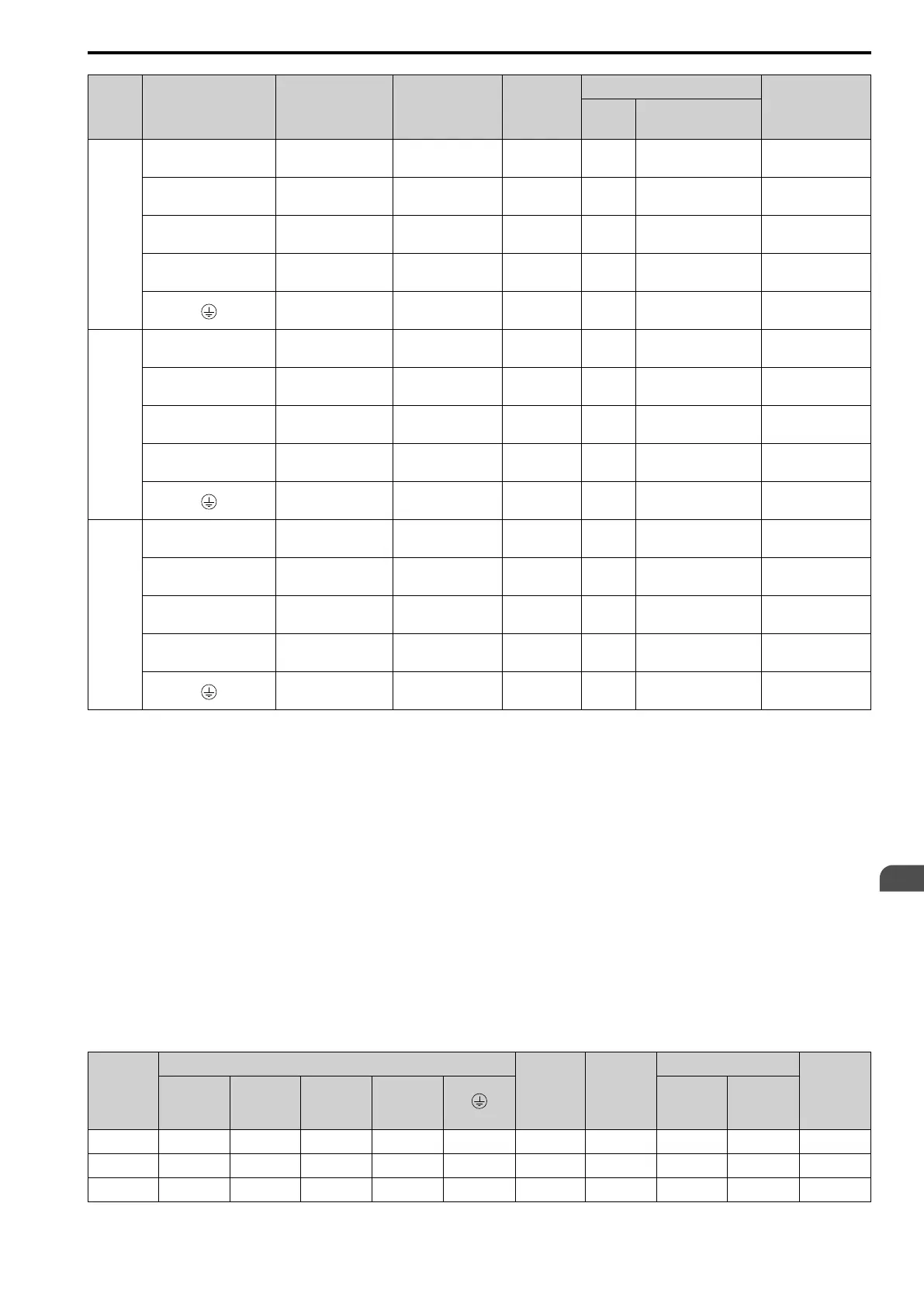

■ Closed-Loop Crimp Terminals

To comply with UL standards on drive models 4208 to 4675, use UL-approved closed-loop crimp terminals. Use

the tools recommend by the terminal manufacturer to crimp the closed-loop crimp terminal. The manufacturer

recommends closed-loop crimp terminals from JST Mfg. Co., Ltd. and insulation caps from Tokyo DIP Co., Ltd.

Comply with local standards for correct wire gauges in the region where the drive is used.

Contact the manufacturer or your nearest sales representative to order.

Refer to Table 5.8 to select crimp terminals as specified by drive model and wire gauge.

Note:

To comply with UL standards, use only insulated crimp terminals or crimp terminals with insulation tubing. Use UL-Listed, vinyl-

coated insulated copper wires for operation with a continuous maximum permitted temperature of 75 °C at 600 V.

Table 5.8 Closed-Loop Crimp Terminals and Insulation Caps for 400 V Class

Model

Recommended Gauge (AWG, kcmil)

Terminal

Screw Size

Crimp

Terminal

Model

Crimping Tool

Insulation

Cap Model

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

-, +1 +3 Tool Model Die Jaw

4002, 4004 - - - - 12 M4 R5.5-4 YA-4 AD-900 TP-005

4005 - 4012 - - - - 10 M4 R5.5-4 YA-4 AD-900 TP-005

4018, 4023 - - - - 10 M5 R5.5-5 YA-4 AD-900 TP-005

Loading...

Loading...