Troubleshooting

7

7.4 Faults

SIEPYEUOQ2A01A AC Drive Q2A Technical Manual 269

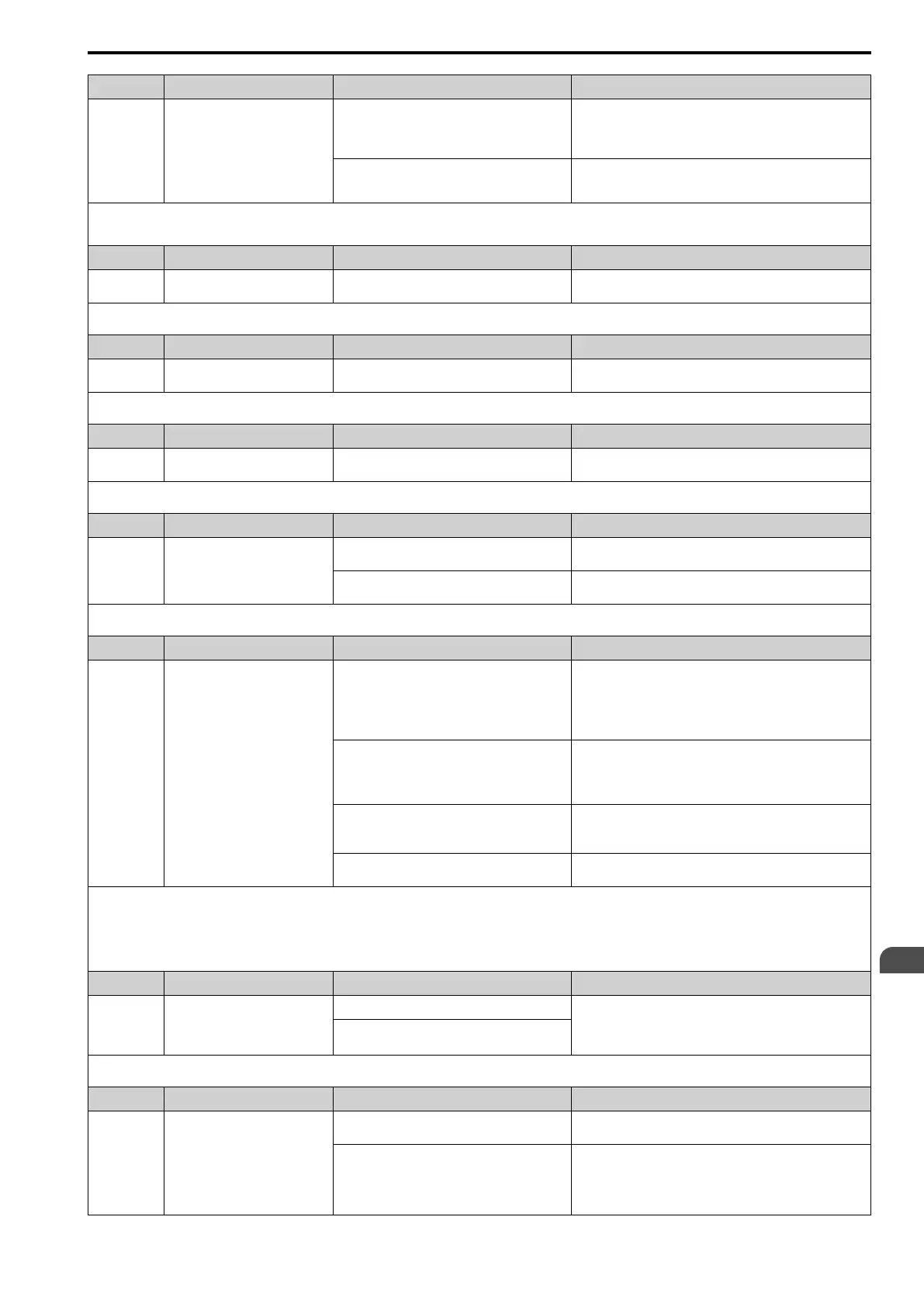

Code Name Causes Possible Solutions

qFL1

EEPROM Memory Q2pack Data

Error

There is an error in the EEPROM peripheral circuit. • Re-energize the drive.

• If the fault stays, replace the control board or the drive. For

information about replacing the control board, contact the

manufacturer or your nearest sales representative.

There is a problem with the EEPROM data. Set A1-03 = 2220, 3330 [Init Parameters = 2-Wire Initialization,

3-Wire Initialization] to initialize the drive, then upload the

Q2dev project to the drive again.

Note:

• The drive detects this error if there is an error in the Q2pack program that was saved to EEPROM.

• Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

qFL2 Q2pack Fault 2

There was a fault in the Q2pack program. Examine the Q2pack program and remove the cause of the fault.

This is not a drive fault.

Note:

Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

qFL3 Q2pack Fault 3

There was a fault in the Q2pack program. Examine the Q2pack program and remove the cause of the fault.

This is not a drive fault.

Note:

Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

qFL Q2pack Fault

There was a fault in the Q2pack program. Examine the Q2pack program and remove the cause of the fault.

This is not a drive fault.

Note:

Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

rF Braking Resistor Fault

The resistance of the dynamic braking option that is

connected to the drive is too low.

Use a dynamic braking option that fits the model and duty rating

of the drive.

A regenerative converter, regenerative unit, or

braking unit is connected to the drive.

Set L8-55 = 0 [DB IGBT Protection = Disable].

Note:

Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

rH Braking Resistor Overheat

The deceleration time is too short and excessive

regenerative energy is flowing back into the drive.

• Check the load level, deceleration time, and speed.

• Decrease the load.

• Increase the value set in C1-02 [Decel Time 1], C1-04 [Decel

Time 2], C1-06 [Decel Time 3], or C1-08 [Decel Time 4].

• Use a dynamic braking option that lets you use more power.

The duty cycle is too high. Examine the duty cycle.

Note:

When L8-01 = 1 [3%ERF DBR Protection = Enabled], the

maximum braking duty cycle is 3%.

The braking load is too large. • Calculate the braking load and braking power again, and

decrease the braking load.

• Use a braking resistor that improves braking power.

The braking resistor is not sufficient. Use the braking resistor specifications to select a sufficient

braking resistor.

Note:

• The drive detects this error if the braking resistor overheat protective function is active.

• The magnitude of the braking load causes the braking resistor overheat alarm, NOT the surface temperature. If the duty cycle is higher than the braking resistor rating, the

drive will show the alarm.

• Do a Fault Reset to clear the fault.

• L8-01 enables fault detection.

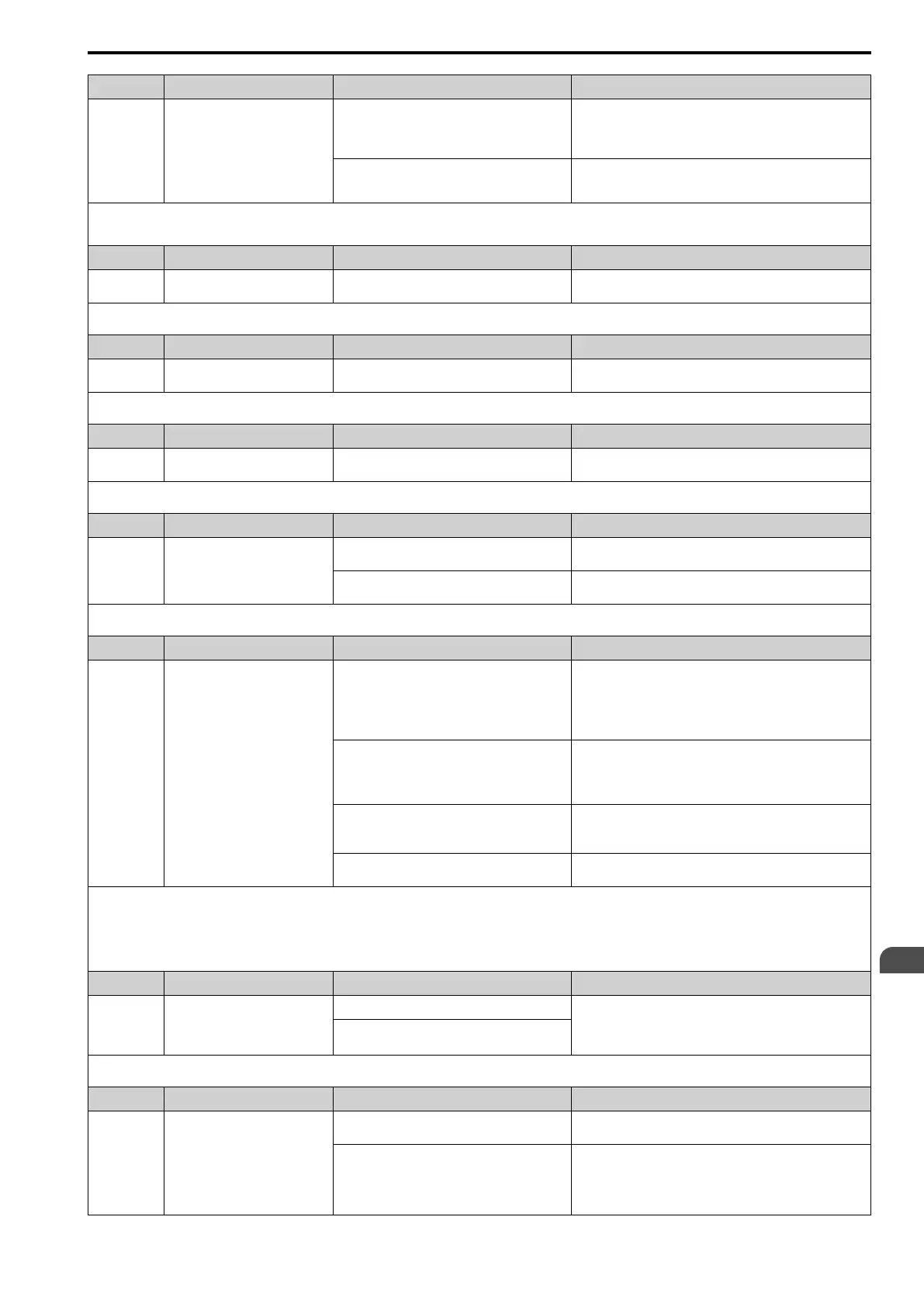

Code Name Causes Possible Solutions

rr Dynamic Braking Transistor Fault

The drive control circuit is damaged.

There is a malfunction in the internal braking

transistor of the drive.

• Re-energize the drive.

• If the fault stays, replace the control board or the drive. For

information about replacing the control board, contact the

manufacturer or your nearest sales representative.

Note:

Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

SC Short Circuit/IGBT Failure

Overheating caused damage to the motor or the

motor insulation is not satisfactory.

Measure the motor insulation resistance, and replace the motor if

there is electrical conduction or unserviceable insulation.

The motor main circuit cable is contacting ground

to make a short circuit.

• Examine the motor main circuit cable for damage, and repair

short circuits.

• Measure the resistance between the motor main circuit cable

and the ground terminal. If there is electrical conduction,

replace the cable.

Loading...

Loading...