12.2 b: APPLICATION

540 SIEPYEUOQ2A01A AC Drive Q2A Technical Manual

• I control

I control is the integral of the deviation. It uses an integral value of the deviation to output the product (the

controlled output). I control helps align the feedback value and the target value.

• D control

D control is the derivative of the deviation. D control has an effect on drive output when there are sudden, large

changes in the output. It quickly returns drive output to the value before the sudden change. It multiplies a time

constant by a derivative value of the deviation (slope of the deviation), and adds that result to PID input to

calculate the deviation of the signal, then it corrects the deviation.

Note:

D control has causes less stable operation because the noise changes the deviation signal. Use D control only when necessary.

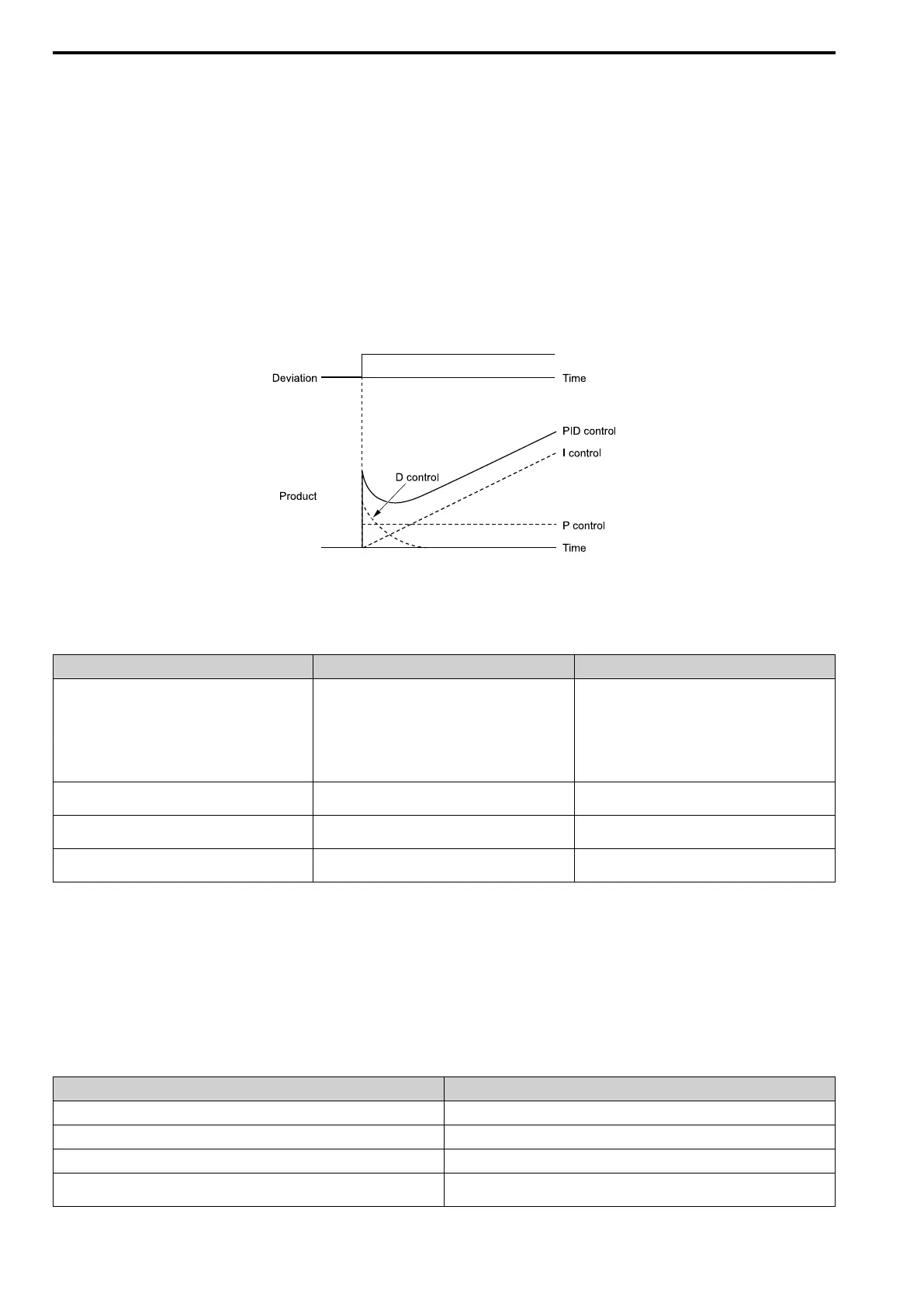

■ PID Control Operation

The modified output (output frequency) changes when the drive uses PID control to keep the deviation (the

difference between the target value and the feedback value) constant.

Figure 12.28 PID Control Operation

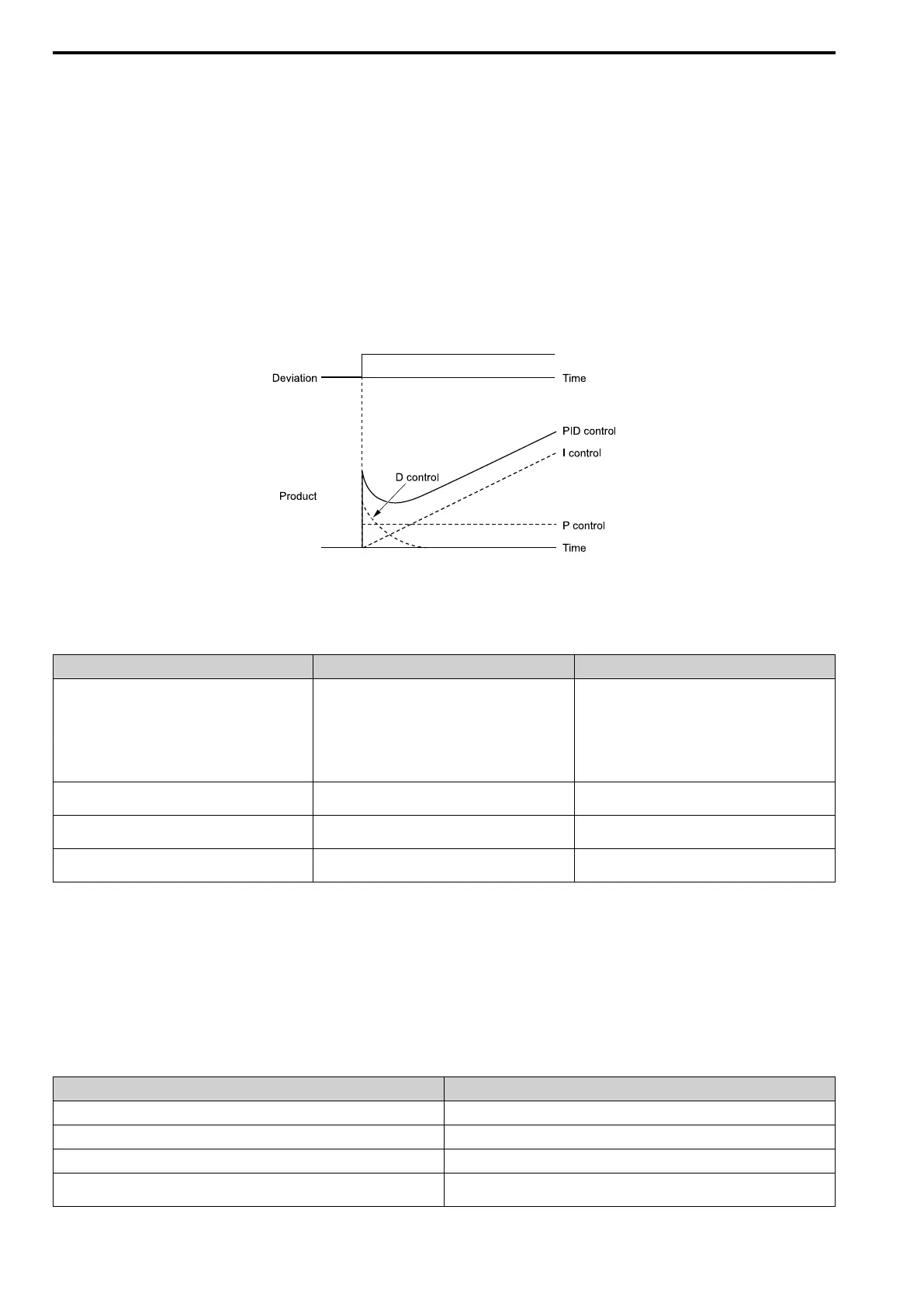

■ PID Control Applications

Table 12.9 PID Control Applications

Application Description Sensors Used

Speed control • The drive uses a feedback signal for the machine

speed, and adjusts that speed to align with the target

value.

• The drive uses speed data from other machinery as the

target value to do synchronous control. The drive then

adds that target value to the feedback from the

machine it is operating to align its speed with the other

machinery.

Tacho generator

Pressure control The drive uses feedback from the actual pressure to hold

constant pressure.

Pressure sensor

Flow control The drive uses feedback from the actual flow to hold

constant flow.

Flow rate sensor

Temperature control The drive uses feedback from the actual temperature to

control a fan and hold constant temperature.

Thermocoupler, thermistor

■ Input Methods for the PID Setpoint

Use b5-01 = 1 [PID Enable = Enabled] and b5-70 to b5-72 to select how the PID setpoint is input to the drive.

When b5-70 = 0 [PID MainRefMode = PID only] or b5-70 = 1 [Fref + PID] and b5-72 = 0 [PID D-FF Mode =

D=Fdback], the frequency reference set in b1-01 [Freq. Ref. Sel. 1] or b1-15 [Freq. Ref. Sel. 2] will be the PID

setpoint, or the one of the values shown in Table 12.10 will be the PID setpoint.

When b5-70 = 1 [PID MainRefMode = Fref + PID] or b5-70 = 1 [Fref + PID] and b5-72 = 0 [PID D-FF Mode

= D=Fdback], one of the inputs in Table 12.10 will be the PID setpoint.

Table 12.10 Input Methods for the PID Setpoint

Input Methods for the PID Setpoint Setting

Multi-function analog input terminal AI1 Set H3-02 = 10 [AI1 Function Selection = PID SetPoint].

Multi-function analog input terminal AI2 Set H3-10 [AI2 Function Selection] = 10 .

Multi-function analog input terminal AI3 Set H3-06 [AI3 Function Selection] = 10.

Modbus register 0006H Sets Modbus register 000FH (Control Selection Setting) bit 1 to 1 (PID setpoint input).

Enters the PID setpoint to Modbus register 0006H (PID Target, 0.01% units, signed).

Loading...

Loading...