43

ZN

System Manual

Section 3 BASIC KNOWLEDGE OF CLEAN SENSING SYSTEMS

Section 3

Feedback Control

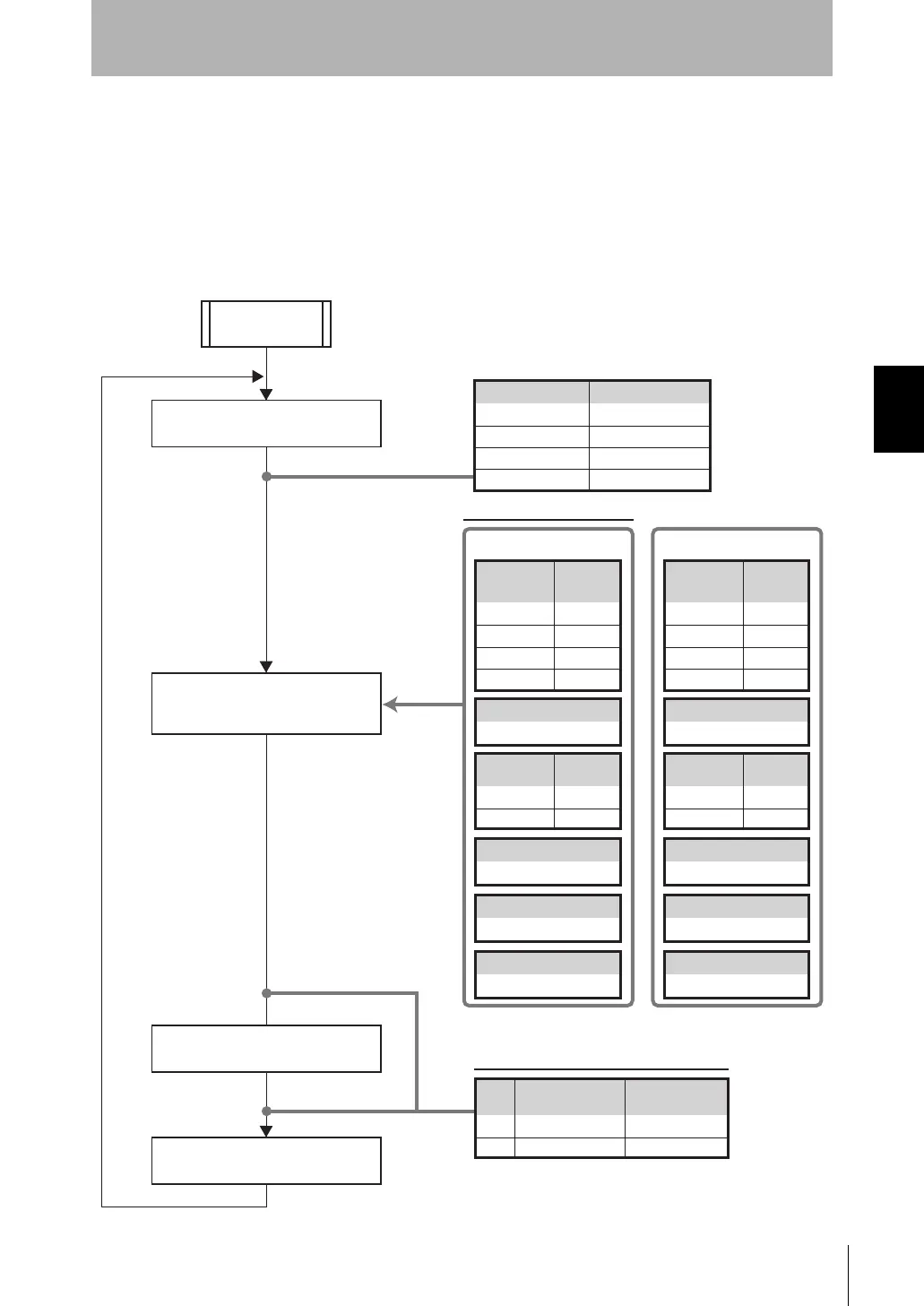

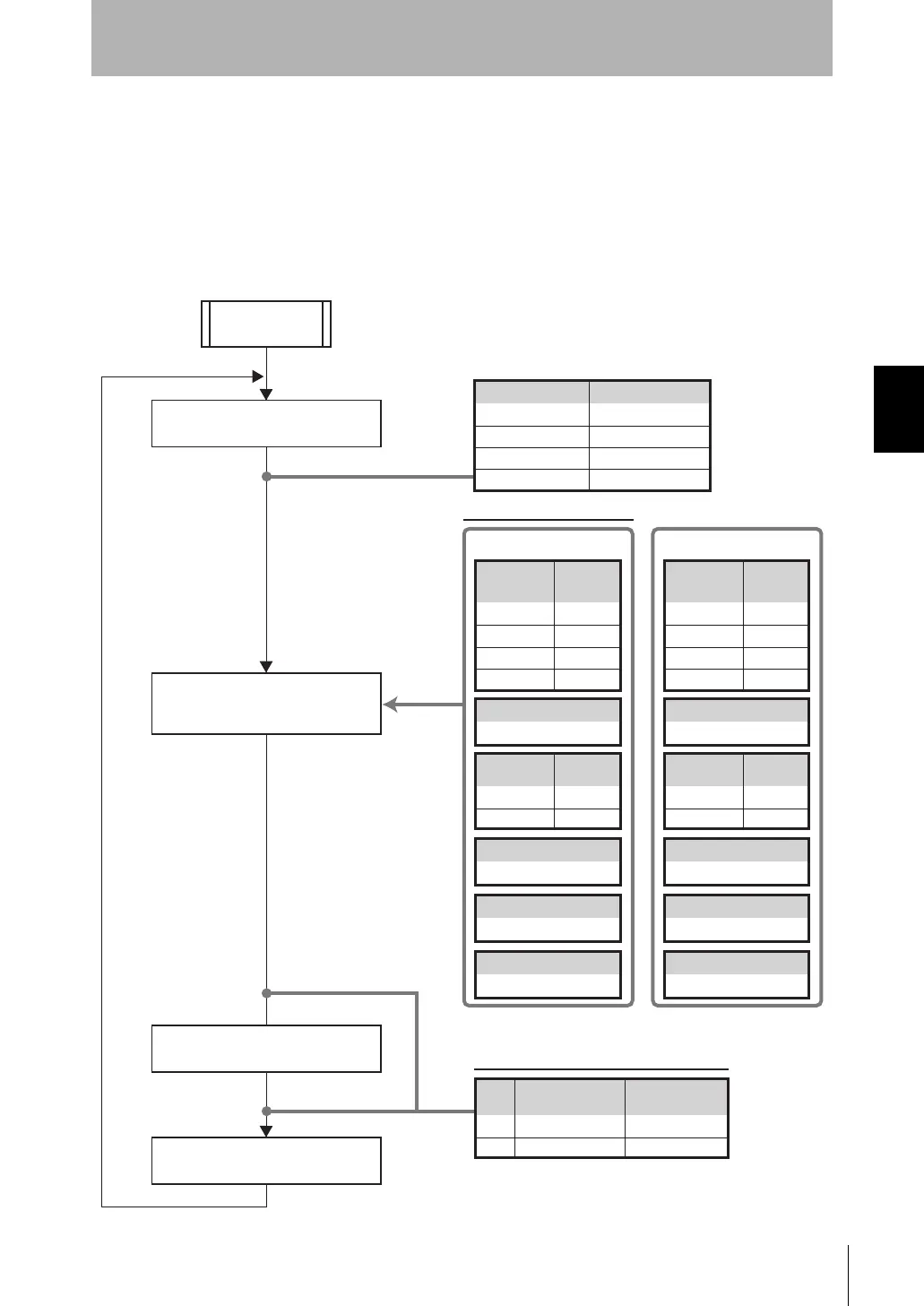

• Flow of processing on Interface Unit

The following shows an example of processing flow during measurement and the data

to be used when feedback processing is performed under the following conditions:

• The Air Clean Unit (ID:1) is controlled based on the larger value of the Air Particle

Sensors on channels 1ch and 2ch.

• The Air Clean Unit (ID:2) is controlled based on the average value of Air Particle

Sensors on channels 3ch and 4ch.

Measurement result calculated

for each measurement time

Measured air volume level

calculated based on feedback

parameters

Measurement result

Air Particle Sensor

1 3500

Measurement result table (example)

Calculation method

Target level

Feedback type

MAX

1000

Constant

Control air volume level value

is sent by communications.

Start of

measurement

Area 1

Low power air volume level

3

2 2000

3 2500

4 3100

Calculation of control air volume

level value for each area

Enabled/

disabled

1ON

2ON

3 OFF

4 OFF

Air Particle

Sensor

Channel

Enabled/

disabled

1ON

2 OFF

Air Clean Unit

ID

Calculation method

Target level

Feedback type

AVE

1000

Constant

Area 2

Low power air volume level

2

Enabled/

disabled

1 OFF

2 OFF

3ON

4ON

Air Particle

Sensor

Channel

Enabled/

disabled

1 OFF

2ON

Air Clean Unit

ID

Calculation of control air volume level value

and measurement result for control (example)

1 3500

2 2800

Measurement result

for control

Area

Control air volume

level value

5

3

Setting values

to be used

3basic.fm43ページ2007年6月28日 木曜日 午前9時18分

Loading...

Loading...