OPTIMUM

MASCHINEN - GERMANY

Version 1.1.6 dated 2014-10-16 Page 97Original operating instructions

F150 GB

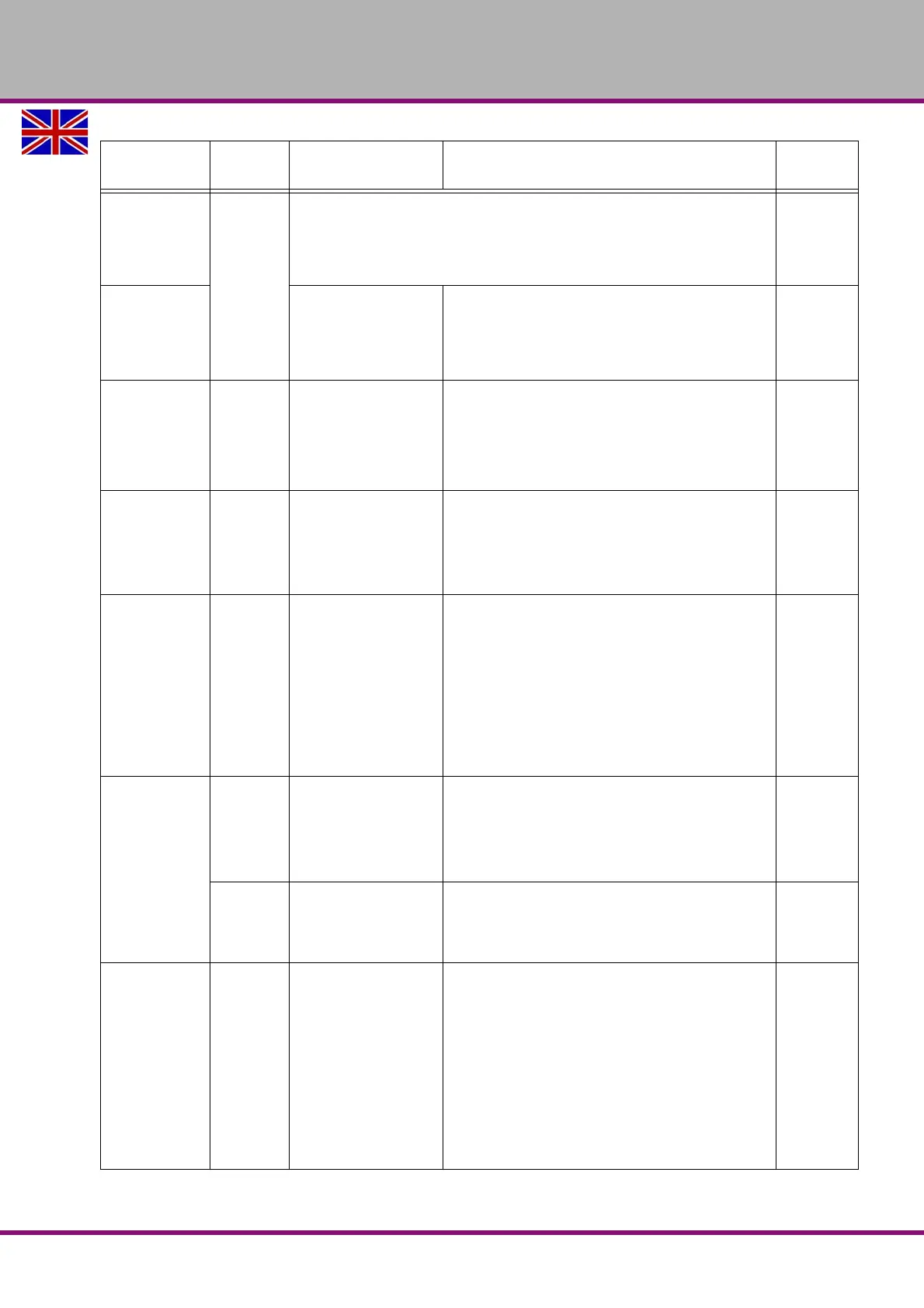

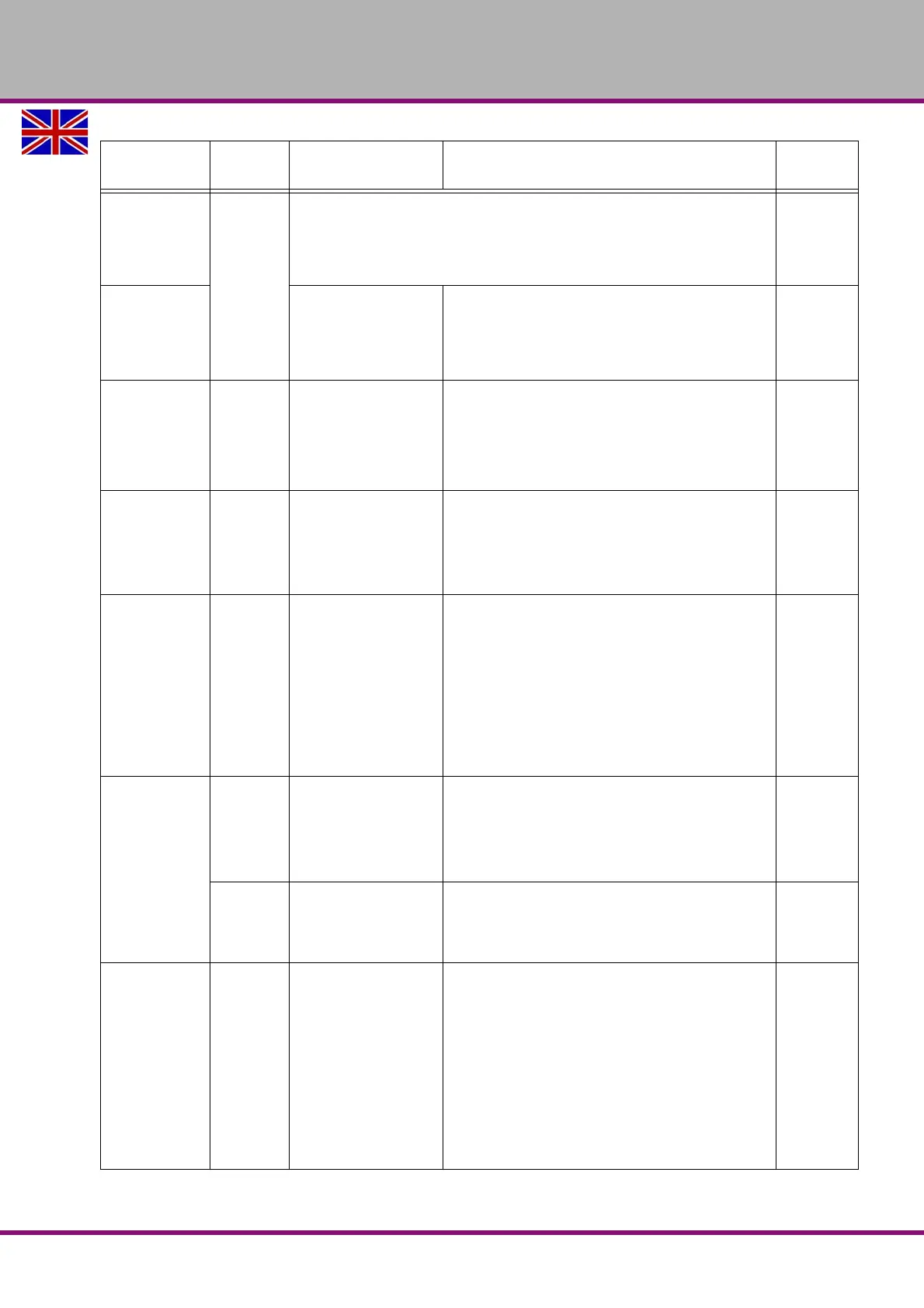

Every week

CNC- milling machine

"Data backup on the control“ on page 49

Every week

Oiling

Lubricating

Oil all bare steel surfaces. Use an acid-free oil,

e.g. weapon oil or motor oil.

Press the push-button of the central lubricating

system.

Every week

Cooling

lubricant tank

Status control of fill-

ing level

Check for liquid level, concentration, pH value,

bacteria and fungal decay.

"Cooling lubricants and tanks“ on page 108

every week

Cooling

lubricant

pH value measuring

Check the ph-value. If required, replace the cool-

ing lubricant.

"Inspection plan for water-mixed cooling lubri-

cants“ on page 109

Every week

Drip feed lubricator

Compressed air cylinder

Filling level control

Check the liquid level and refill if required.

Every month

Gear belt

Spindle head

Check

Readjusting

Replacing

Check the drive belt on wear and excessive clear-

ance.

If required, readjust the gear belt and/or replace it.

Air purge

Check

Readjusting

Check the function of the air purge.

If necessary re-adjust the amount of air.

"Air purge“ on page 102

Annually

Clutch

Coupling Drive Z-, Y-, X-axis

Check

Replacing

Check if coupling is worn and check coupling

slack.

If necessary, replace the coupling.

Interval Where? What? How?

Check

Loading...

Loading...