Version 1.1.1 - 2021-1-25 31Translation of original instruction

MB4 EN

MB4_GB_4.fm

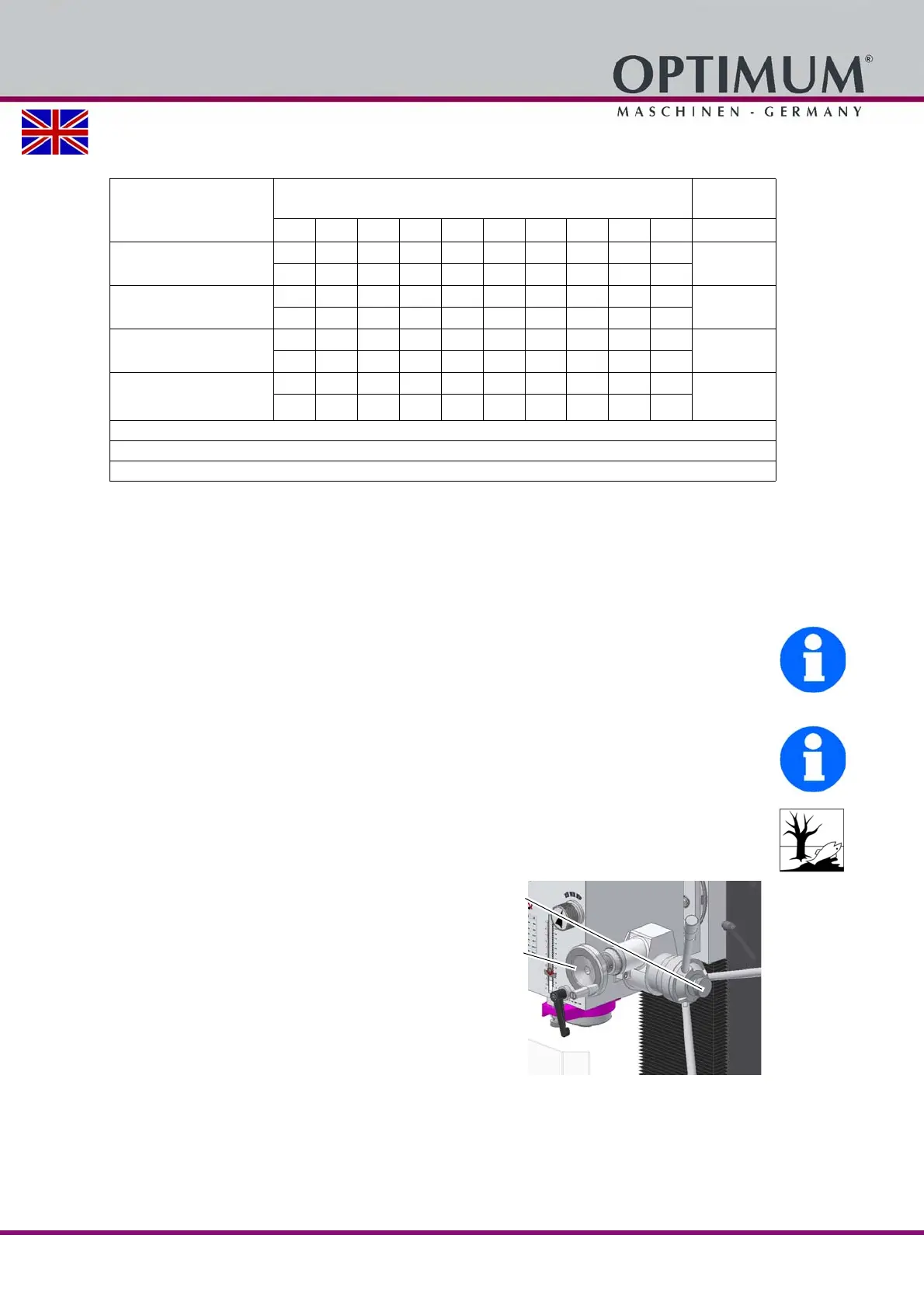

4.8.2 Standard values for speeds with HSS – Eco – twist drills

The above data are standard values. In some cases it may be advantageous to increase or

decrease these values.

A cooling or lubricating agent should be used when drilling.

For stainless materials (e.g. VA – or NIRO steel sheets) do not centre, as this will result in

the material compacting and the drill bit rapidly becoming blunt.

The workpieces need to be tensed inflexibly and stably (vice, screw clamp).

INFORMATION

Friction during the cutting process causes high temperatures at the cutting edge of the tool. The

tool should be cooled during the milling process. Cooling the tool with a suitable cooling lubri-

cant ensures better working results and a longer edge life of the cutting tool.

INFORMATION

Use a water-soluble environmentally friendly emulsion as cooling lubricant procured from a spe-

cialist retailer.

Make sure that the cooling lubricant is properly absorbed. Respect the environment when dis-

posing of lubricants and coolants. Follow the manufacturer’s disposal instructions.

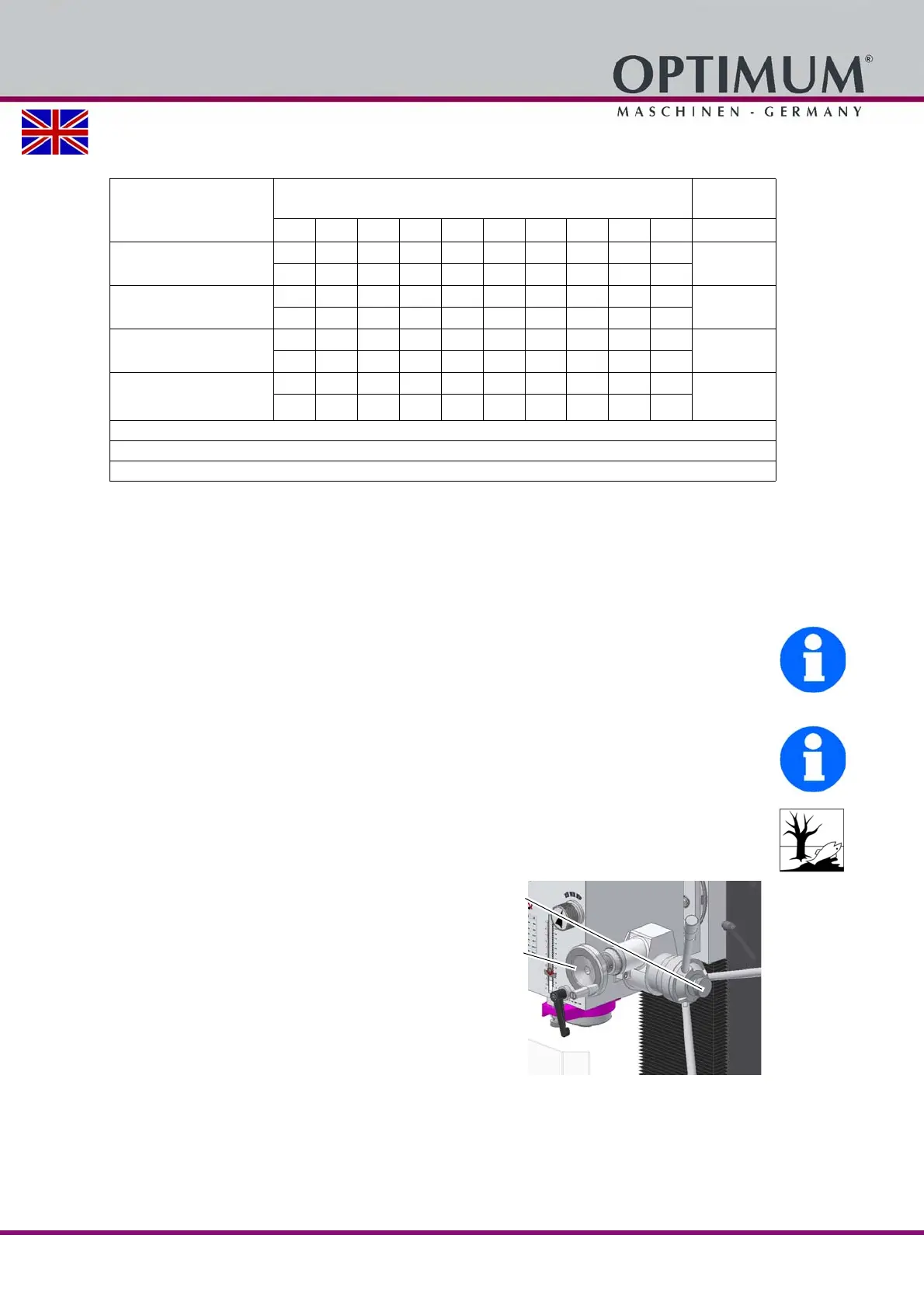

4.9 Manual spindle sleeve feed with the fine feed

Turn the handle screw.

The spindle sleeve lever moves in

direction of the drilling-milling head

and activates the coupling of the fine

feed.

Turn the spindle sleeve fine feed in

order to move the spindle sleeve.

Img.4-4: Handle screw

Material

Drill diameter

Cooling

3)

2345678910

Steel, unalloyed,

up to 600 N/mm

2

n

1)

5600 3550 2800 2240 2000 1600 1400 1250 1120

E

f

2)

0.04 0.063 0.08 0.10 0.125 0.125 0.16 0.16 0.20

Mild steel, alloyed, tempered,

up to 900N/mm

2

n 3150 2000 1600 1250 1000 900 800 710 630

E/oil

f 0.032 0.05 0.063 0.08 0.10 0.10 0.125 0.125 0.16

Mild steel, alloyed, tempered,

up to 1200 N/mm

2

n 2500 1600 1250 1000 800 710 630 560 500

Oil

f" 0.032 0.04 0.05 0.063 0.08 0.10 0.10 0.125 0.125

Stainless steels up to 900 N/

mm

2

e.g. X5CrNi18 10

n 2000 1250 1000 800 630 500 500 400 400

Oil

f 0.032 0.05 0.063 0.08 0.10 0.10 0.125 0.125 0.16

1): Speed [n] in rpm

2): Feed [f] in mm/rev

3): Cooling: E = Emulsion; oil = cutting oil

Loading...

Loading...