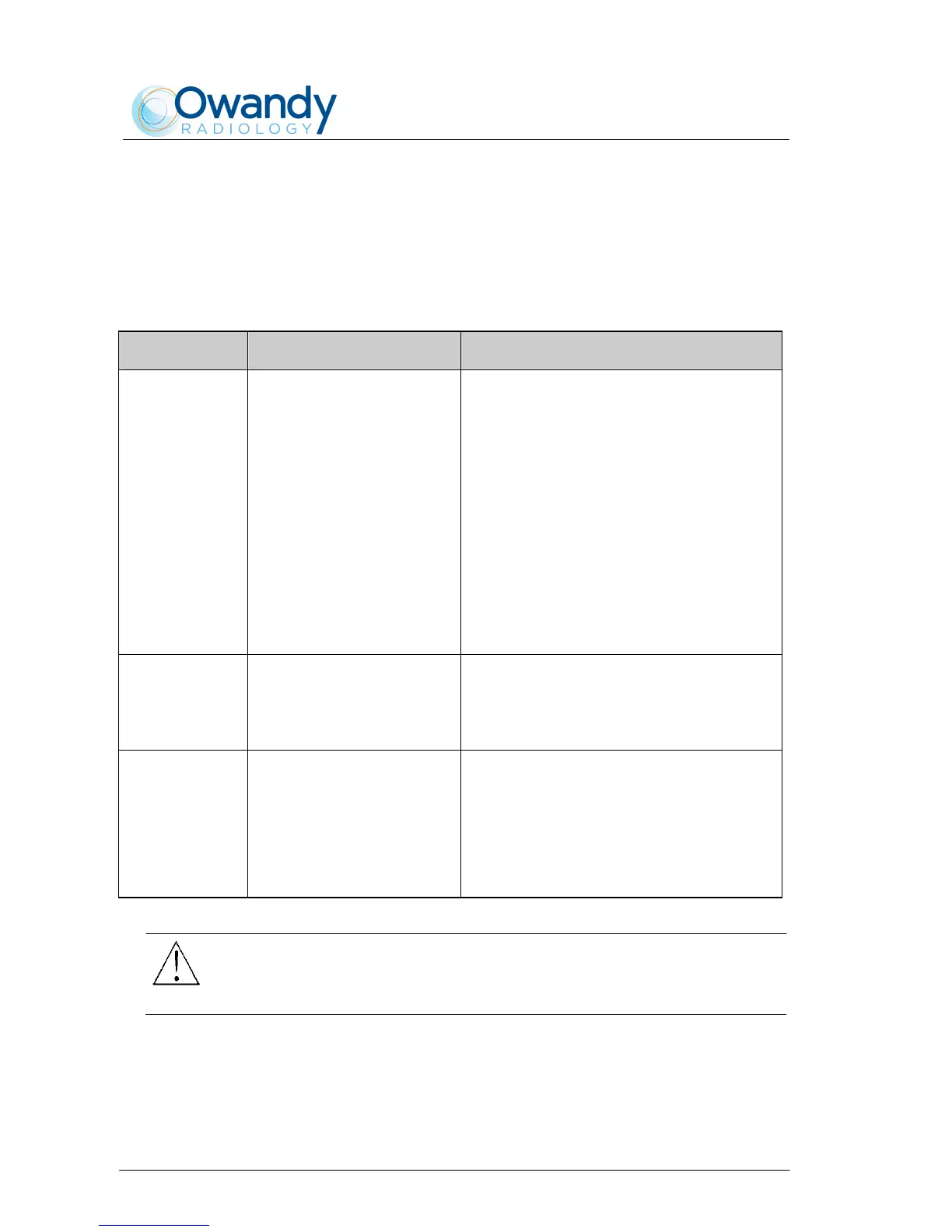

9.1.2 Fatal errors during X-ray emission

Possible anomalies during exposure always interrupt the exposure itself.

Whether there is an acoustic signal or not depends on the time the fault

occurred and on the success of the X-ray interruption procedure.

Displayed

message

ANOMALY type Corrective actions

E04

No emission (breakage in

the filament circuit)

Measure the impedance value between "+"

and "-" of Driver board - connector X2

(HEATER); this value must be lower than

20 ohm.

If the value is greater than 20 ohm, remove

the tubehead plastic covers and measure

the impedance value between J3.IN+ and

J3.IN- of Filament Voltage Regulator board.

If the value is still greater than 20 ohm,

disconnect the cables J3.Fil+ and J3.Fil-

from the Filament terminal strip and

measure the impedance value between

them.

If the measured value is lower than

20 ohm, replace the DP arm, otherwise

replace tubehead and Driver board.

E06

Activation of the back-up

timer

Check integrity of the flat cable connecting

the CPU to the Driver board.

Switch the system off and on again; if the

message is repeated after an exposure,

replace the Driver board and the tubehead.

E07

Protection intervention Switch the system off.

Check the integrity of power cables

between tubehead and timer and

insulation between them and GND (no

short circuit present).

If cables are ok, switch the unit on; if the

message is still present, replace the Driver

board and the tubehead.

WARNING:

When an error signal appears and the buzzer sounds, always switch

the system off. In any case when the back-up timer is triggered it

always interrupts X-ray emission.

Loading...

Loading...