SC-HM910/SC-HM810

8

6 Handling Precautions For Traverse Deck

The laser diode in the traverse deck (optical pickup) may break down due to potential difference caused by static electricity of clothes

or human body.

So. be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

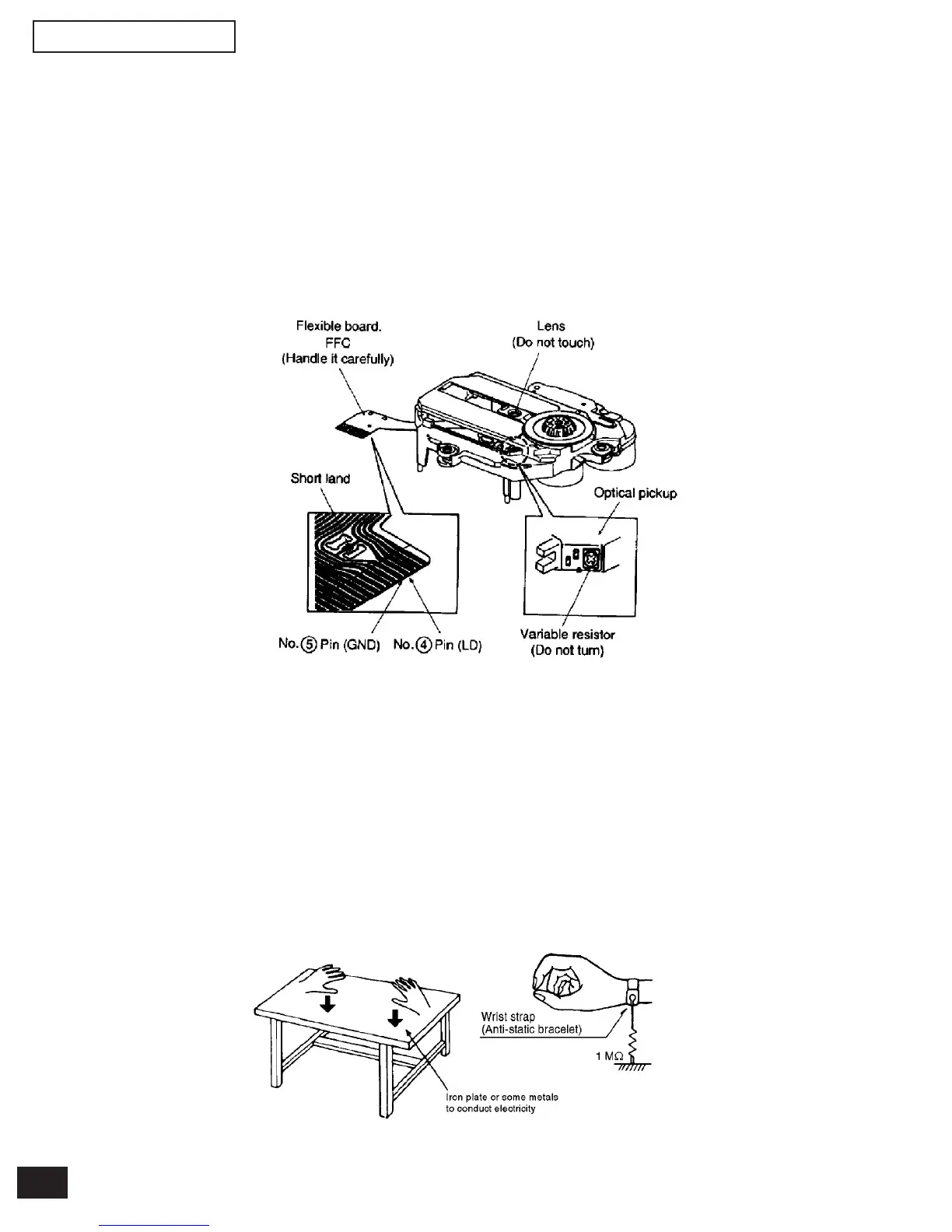

Handling of traverse deck (optical pickup)

1. Do not subject the traverse deck (optical pickup) to static electricity as it is extremely sensitive to electrical shock.

2. The short land between the No. 4 (LD) and No. 5 (GND) pins on the flexible board (FFC) is shorted with a solder build-up to

prevent damage to the laser diode. To connect to the PC board be sure to open by removing the solder build-up and finish the

work quickly.

3. Take care not to apply excessive stress to the flexible board (FFC).

4. Do not turn the variable resistor (laser power adjustment). It has already been adjusted.

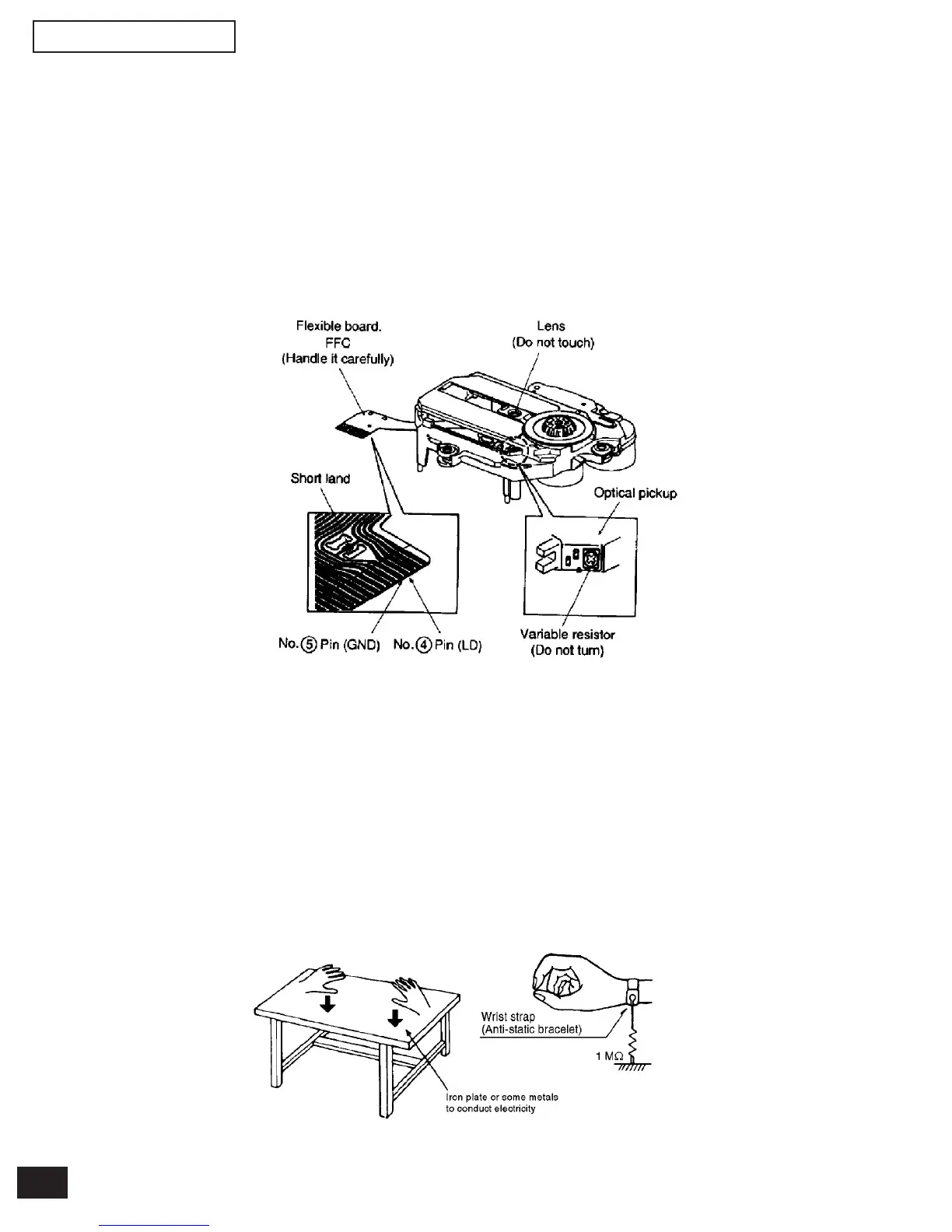

Grounding for electrostatic breakdown prevention

1. Human body groundling

Use the anti-satatic wrist strap to discharge the static electricity from your body.

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area where the traverse deck (optical pickup) isplaced, and ground the

sheet.

Caution:

The static electricity of your clothes will not be grounded through the wrist strap. So, take care not to let your clothes touch the traverse

deck (optical pickup).

Caution when Replacing the Traverse Deck:

The traverse deck has a short point shorted with solder to protect the lazer diode against electrostatics breakdown. Be sure to remove

the solder from the short point before making connections.

Loading...

Loading...