TPD1317e Chapter 2

Page 7

2.1 Propeller Shafts

It is recommended that all engines are mounted on exible mountings, which will reduce the transmission of

noise and vibration, and will prevent hull movements resulting in forces being applied to the engine.

The responsibility for the design and installation of the transmission system connected to the marine gearbox

lies with the boat designer, the boat builder, the naval architect or the engine installer. It is recommended that

a Torsional Vibration Analysis (TVA) is carried out on the complete drive system. Mass Elastic Data on the

engine can be provided on request from Sabre Engines Ltd. The following observations are offered, to show

some of the systems currently in use.

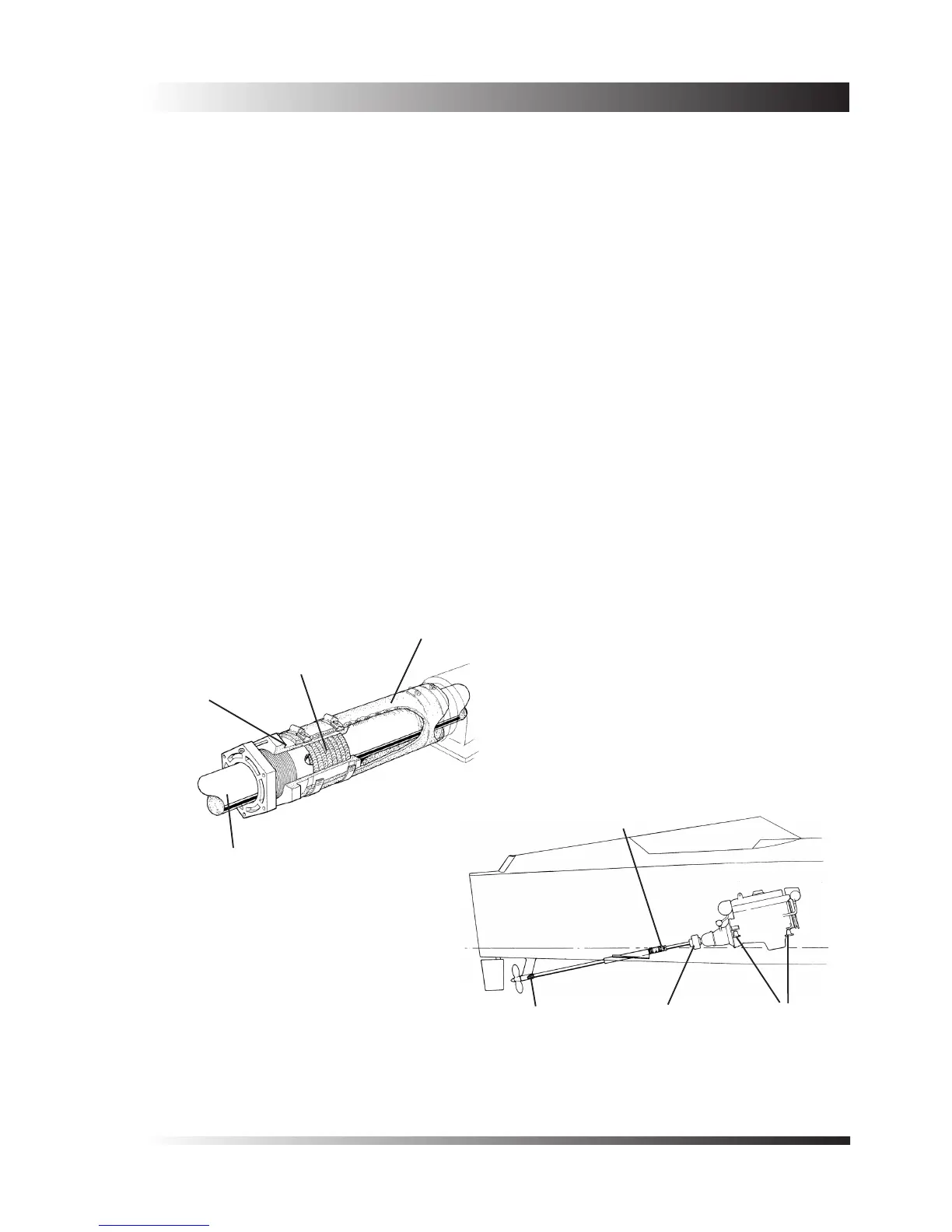

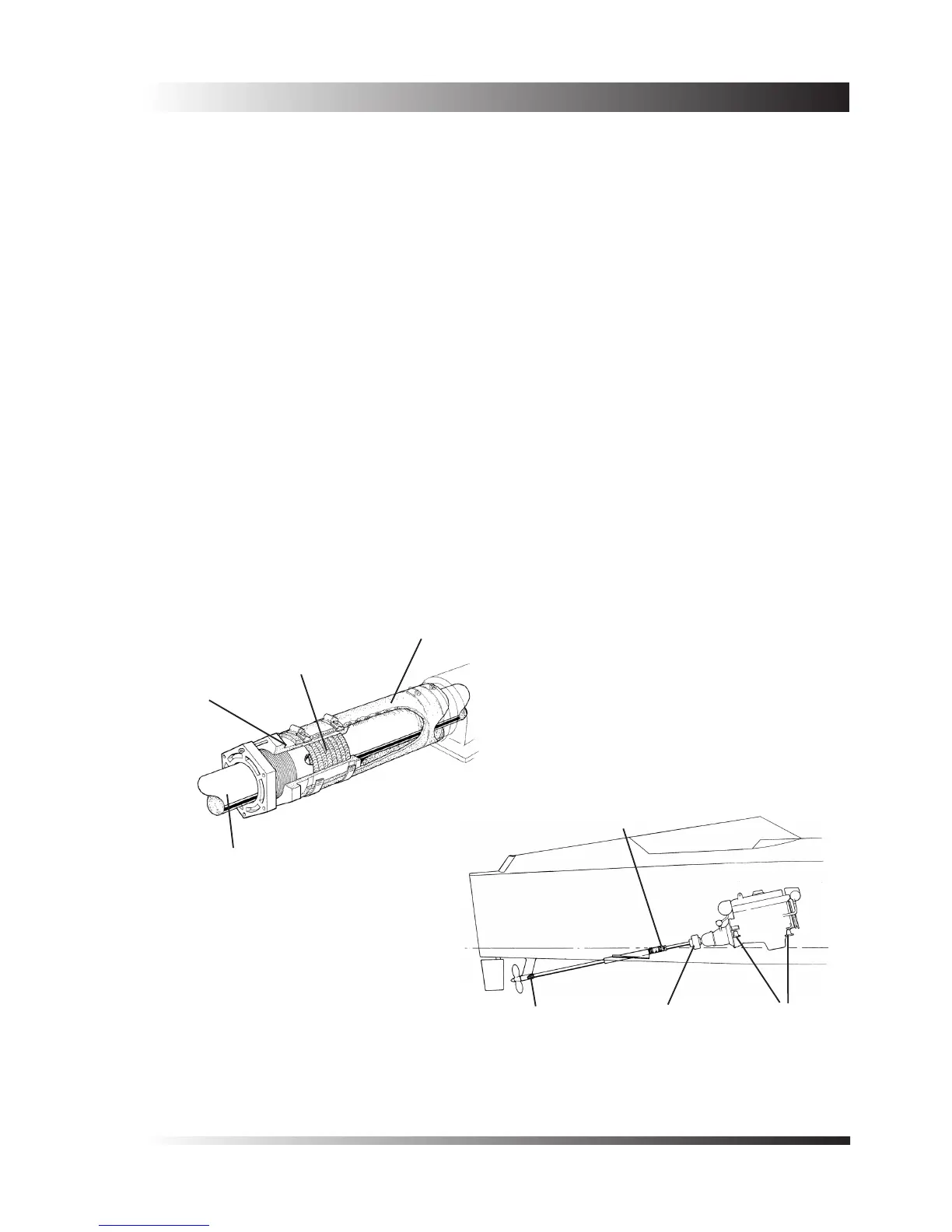

Figure 1 shows a simple arrangement, where the propeller shaft is supported only by the gearbox coupling

and an outboard rubber bearing at the propeller end. Entry of water into the boat is prevented by a shaft seal,

which must be exibly mounted to allow for engine movement. A exible shaft coupling is tted to the gearbox

coupling, to allow momentary angular misalignment in operation.

This system is only suitable for applications where the speed, diameter, and unsupported length of the propeller

shaft will not induce ‘whirling’ (i.e. the centrifugal force generated by the speed of rotation is not sufcient to

bend the shaft into a bow shape).

Propeller Shafts and Couplings

å

Flexibly mounted

shaft seals

Cutless

bearing

Flexible shaft

coupling

Flexible

mountings

Reinforced

rubber hose

Graphited asbestos

string

Stufng

box

Shaft

Loading...

Loading...