TPD1317e Chapter 3

Page 13

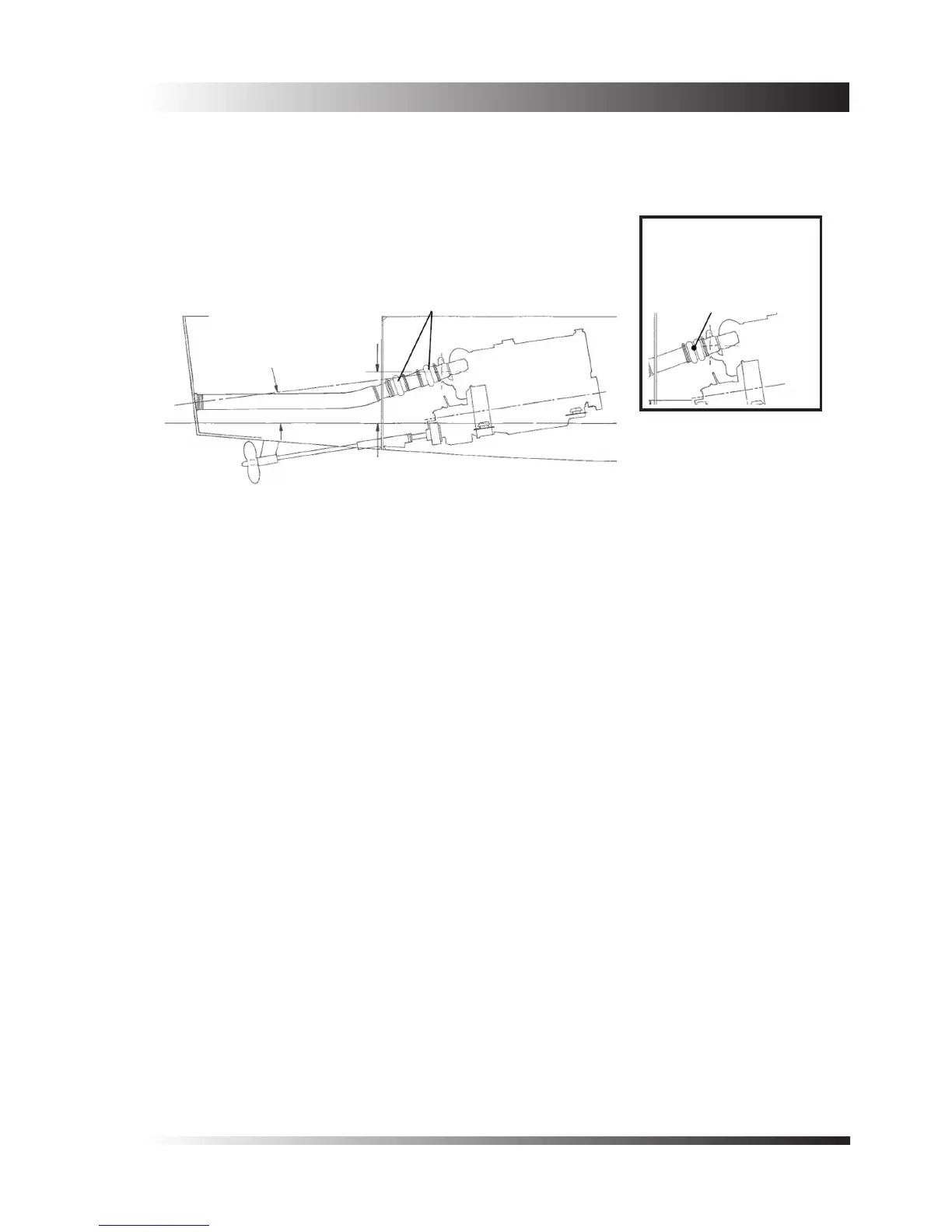

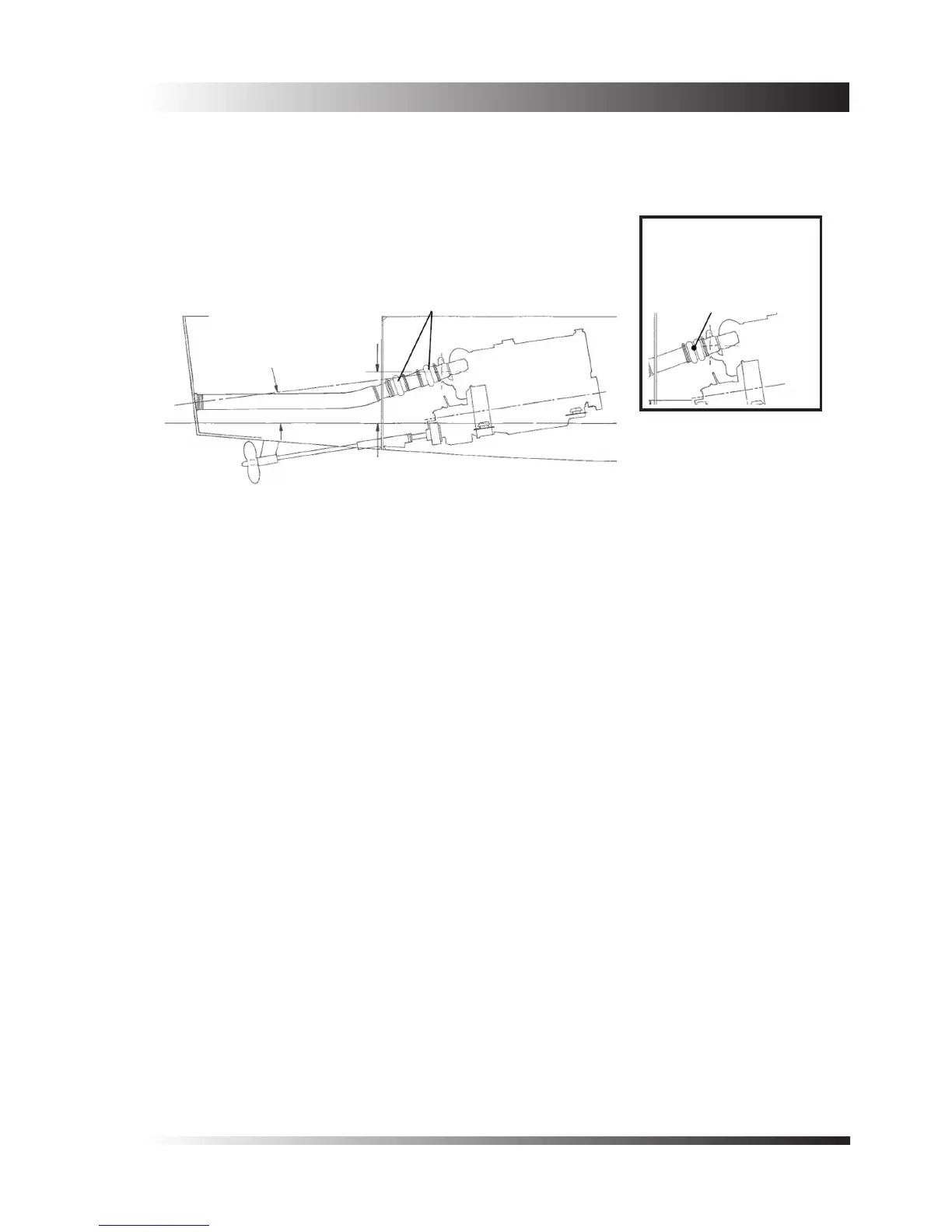

Due consideration must be given to providing exibility in the exhaust hose, particularly if the engine is exibly

mounted. Where the exhaust hose must pass through a bulkhead immediately behind the engine it is preferable

that the arrangement shown in Figure 3 is adopted, using rubber bellows to provide exibility. Note that the

bellows should be in an unstrained condition when tted.

3.2 Dry Systems

Dry exhaust systems for marine installations need careful design to minimize the disadvantages of enclosing

components that are at a high temperature in conned spaces.

The rst part of a dry system should include a exible connection so that excessive weight is not carried by the

connection to the engine. Connections of the stainless steel bellows type are suitable, but care must be taken

to ensure that they are only required to accommodate movements that do not involve twisting the ends of the

bellows relative to each other.

The remainder of the exhaust system should be well insulated to avoid re risk.

If there is a long exhaust run which gains height as it leaves the engine, it may be necessary to incorporate a

trap to collect condensate and allow it to be drained.

Figures 4, 5 , 6, 7 & 8 show typical systems. The minimum bore of the exhaust pipe should be 76mm (3 inches)

for turbocharged engines, 63mm (2.5 inches) for naturally aspirated engines.

Point of water

injection to be

200mm (8 inches)

minimum height

above water line

5

o

minimum average fall

For turbocharged 6 cylinder

engines use silicone rubber

bellows

For turbocharged 6

cylinder engines, use

a single double hump

bellows where space is

restricted.

Figure 3 - Movement of the engine on the exible mounts must not be restricted by

the exhaust hose. Use rubber bellows as shown where space is restricted.

Loading...

Loading...