TPD1317e Chapter 6

Page 33

Fuel Systems

Design and assembly faults in the fuel system are responsible for many problems with marine diesel

engines. A good system is not hard to achieve, being largely a matter of avoiding obvious pitfalls.

6.1 Fuel Connections

A common reason for service problems with fuel systems is the use of poor or incompatible connectors, where

the pressure tightness depends upon the use of sealing compounds, hose clamps, bre washers trapped

between inadequate and unmachined faces, or compression ttings which have been over-tightened to the

point where they no longer seal.

Cleanliness during initial assembly is also of vital importance, particularly when fuel tanks are installed, as

glass bres and other rubbish may enter tanks through uncovered apertures.

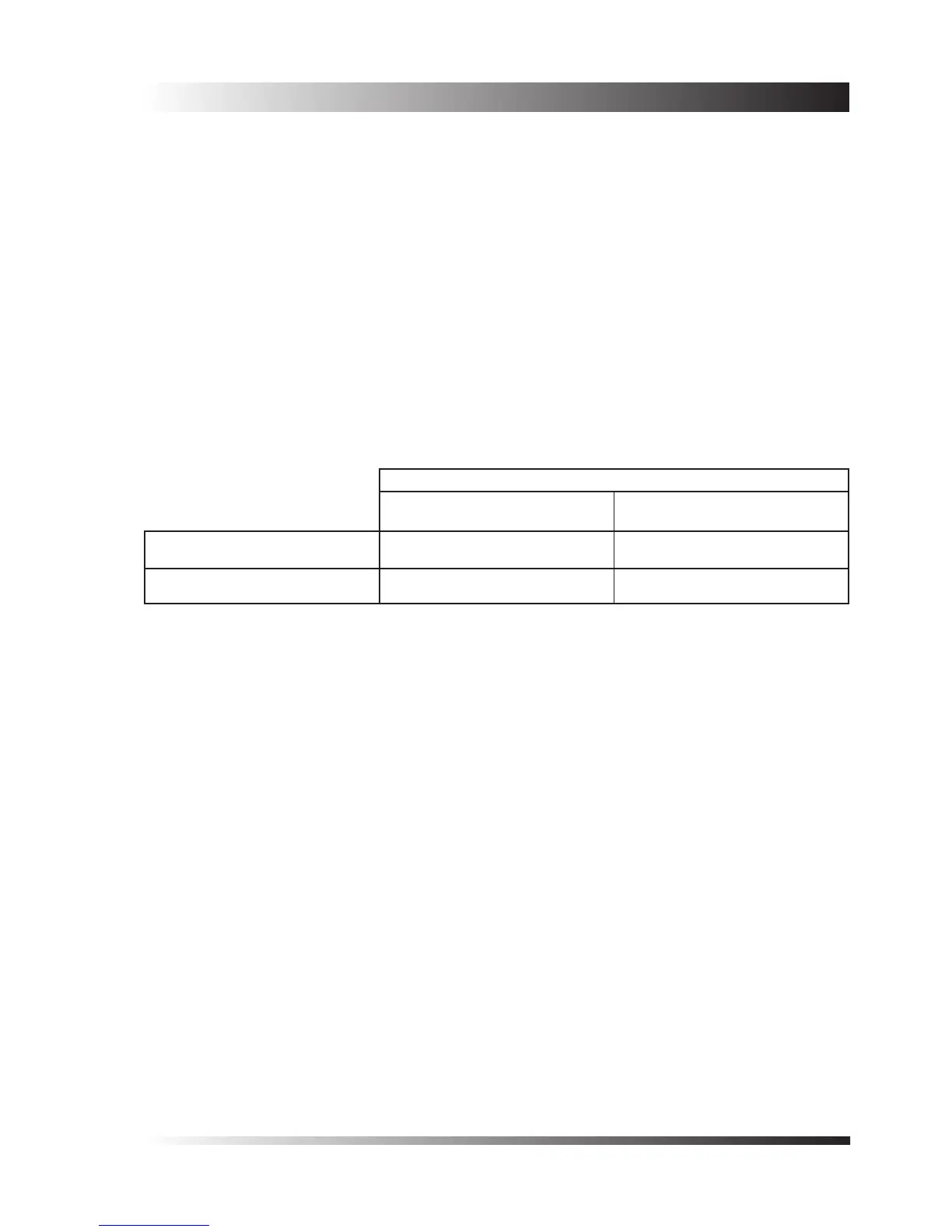

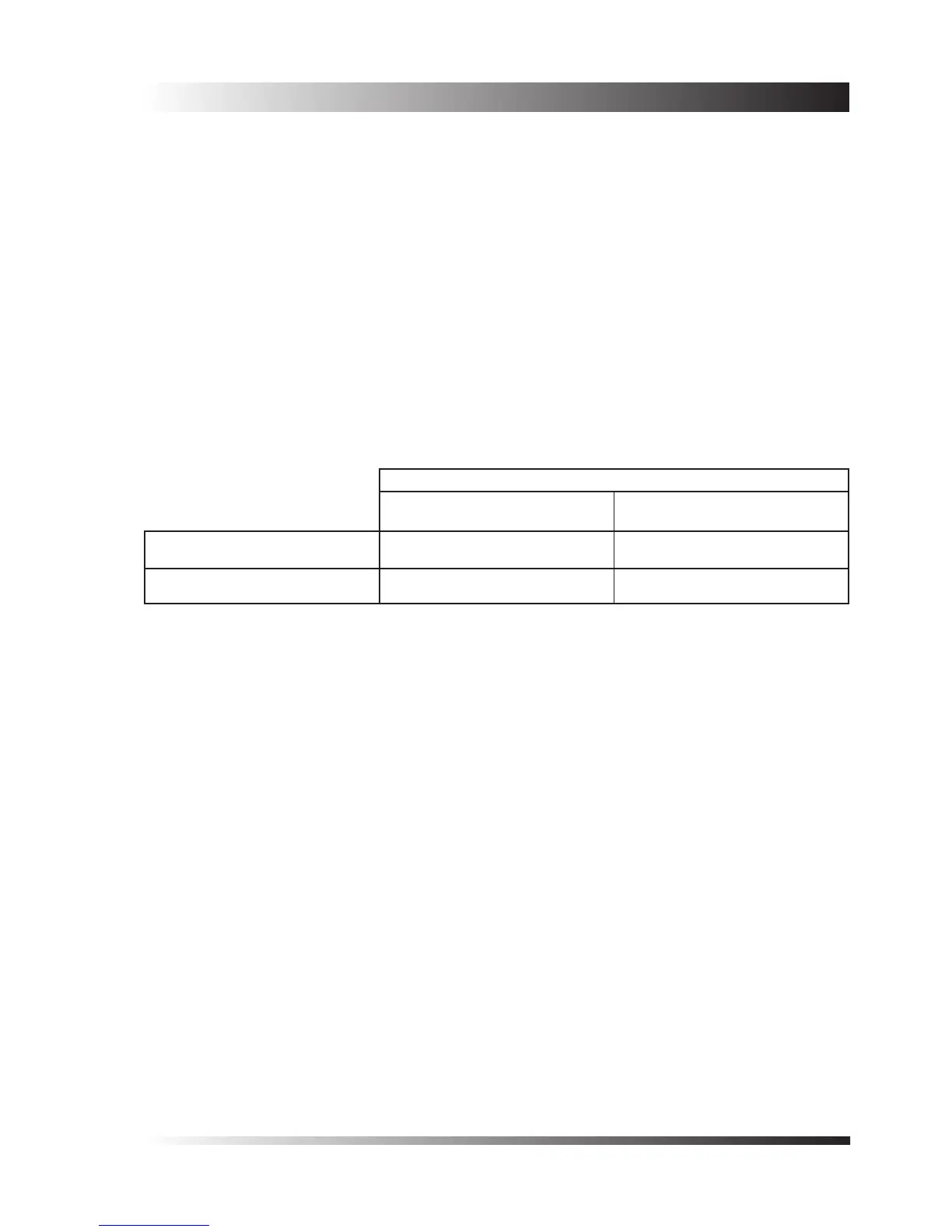

Thread details of the connections on the engines for fuel pipes

Model

M300Ti / M265Ti

M225Ti / M215C / M185C / M135

/ M130C / M115T / M92B / M92

Fuel feed 3/8” BSP 1/2” UNS

Fuel return 3/8” BSP 7/16” UNS

It is strongly recommended that the exible fuel pipes available as an option with the engine are used, which

are as follows:

Fuel Feed - M300Ti & M265Ti (Pt No 34051)

The free end of the exible pipe has a 3/8” BSP cone ended tting, and is supplied with an adaptor, nut, and

olive to suit 10mm OD steel or copper tube.

- M225Ti / M215C / M185C / M135 / M130 / M115T / M92B & M92 (Pt No 34055)

The free end of the exible pipe has a 1/2” UNS male thread, and is supplied with a nut and olive to suit 5/16”

OD steel or copper tube.

Fuel Return - M300Ti & M265Ti (Pt No 34052)

The free end of the exible pipe has a 3/8” BSP cone ended tting, and is supplied with an adaptor, nut, and

olive to suit 10mm OD steel or copper tube.

- M225Ti / M215C / M185C / M135 / M130 / M115T / M92B & M92 (Pt No 34054)

The free end of the exible pipe has a 7/16” UNS male thread, and is supplied with a nut and olive to suit 1/4”

OD steel or copper tube.

Loading...

Loading...