COOLING SYSTEM

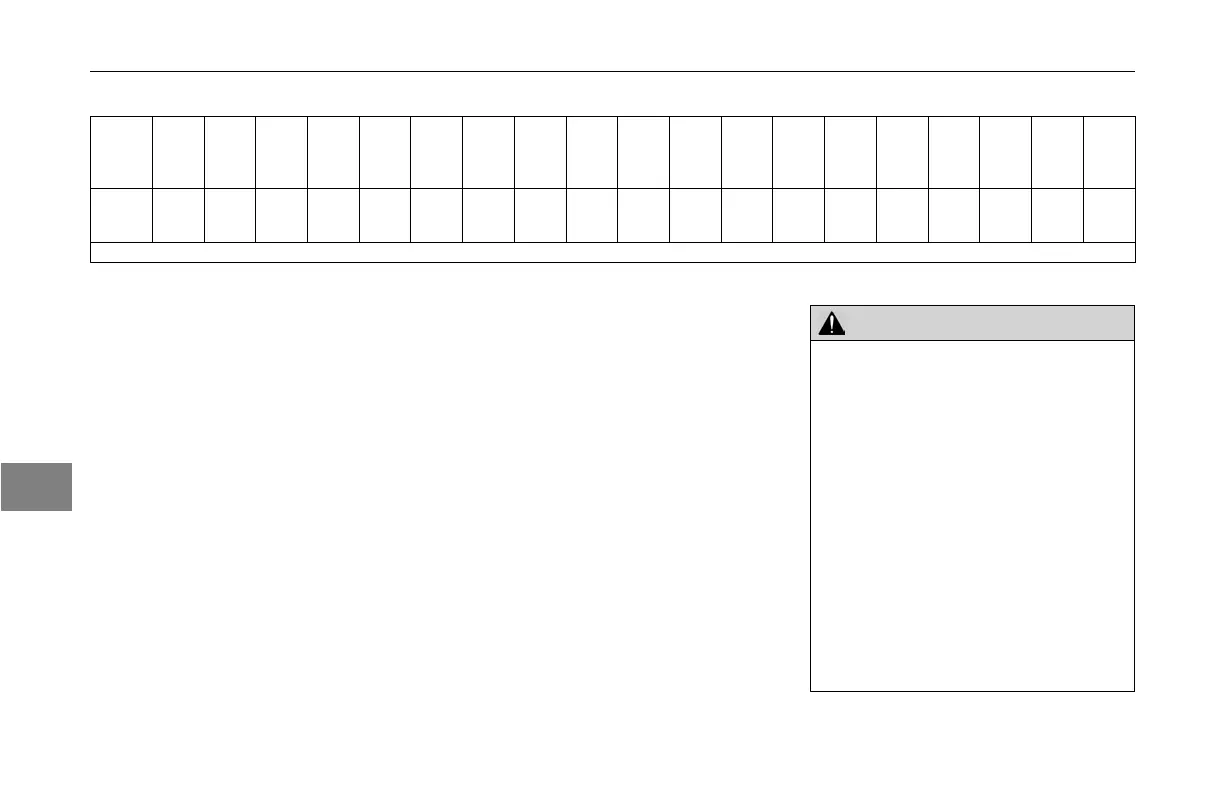

Desired

ELC/

Water

ratio:

0% 10% 15% 20% 25% 30% 35% 40% 45% 50% 55% 60% 65% 70% 75% 80% 85% 90% 100%

Freeze

point

°F

(°C)

+32

(0)

+25

(-4)

+20

(-7)

+15

(-9)

+10

(-12)

+5

(-15)

-5

(-21)

-12

(-24)

-23

(-31)

-34

(-37)

-50

(-46)

-65

(-54)

-75

(-59)

-84

(-64)

-70

(-57)

-55

(-48)

-43

(-42)

-30

(-34)

-5

(-21)

Items in

bold are the recommended levels of concentration.

5

ELC Condition (Contamination and

Inhibitor Concentration)

Perform a

visual inspection of the

ELC. It should have no cloudiness

or oating debris. Determine the

chemical inhibitor concentration level

by using an ELC-specic test kit or

test strips. Inhibitor concentration level

determines corrosion protection. If you

are concerned about possible coolant

quality, contamination, or mechanical

problems, submit a coolant sample for

analysis. Improper maintenance may

cause coolant degradation and could

result in damage to the cooling system

and engine components. Consult

your dealer or the ELC manufacturer’s

representative for recommended ELC

test kits,

test strips, and laboratory

sample procedures.

ELC Extender

Add ELC

extender if necessary at the

maintenance interval under “Cooling”.

Coolant Filter

If your

vehicle came with a

non-chemical lter (“blank lter”),

replace it only with a blank lter at the

interval specied

in the Preventive

Maintenance Schedule

on page 5-12.

Never use

lters that contain SCAs in

an ELC-lled system.

Topping

Off

WARNING!

Removing the ll cap on a hot engine

can cause scalding coolant to spray

out and burn you badly. If the en

-

gine has been in operation within the

previous 30 minutes, be very care

-

ful in removing the ll cap. Protect

face, hands, and arms against escap

-

ing uid and steam by covering the

cap with a large, thick rag. Do not

try to remove it until the surge tank

cools down or if you see any steam

or coolant escaping. In any situation,

remove the cap very slowly and care

-

fully. Be ready to back off if any steam

or coolant begins to escape.

5-72 Y53-6047–2C (04/13)

Loading...

Loading...