TIRES AND WHEEL

Wheel Mounting

and

Fastening

After the vehicle travels about 50 to 100

miles (80 to 160 km), wheel mountings

seat in and will lose some initial torque.

Check hub/wheel mountings after this

initial period and retighten.

Wheel Cap Nut Torque

WARNING!

Never use oil or grease on studs or

nuts; improper torque readings will

result, which could cause improper

wheel clamping and could lead to a

wheel failure resulting in an accident.

Failure to comply may result in death,

personal injury, equipment or property

damage.

Wheel Cap

Nut Torque

At the

rst scheduled lube interval,

have all wheel cap nuts torqued to

their specied

value listed in Wheel

Cap Nut

Torque on page 5-141. After

that, check

wheel cap nuts at least

once a week. Contact an authorized

dealer for information on the proper

installation procedure for the wheels

on your truck. This is a job you may

not be able to do yourself. You need

the right torquing equipment to do it.

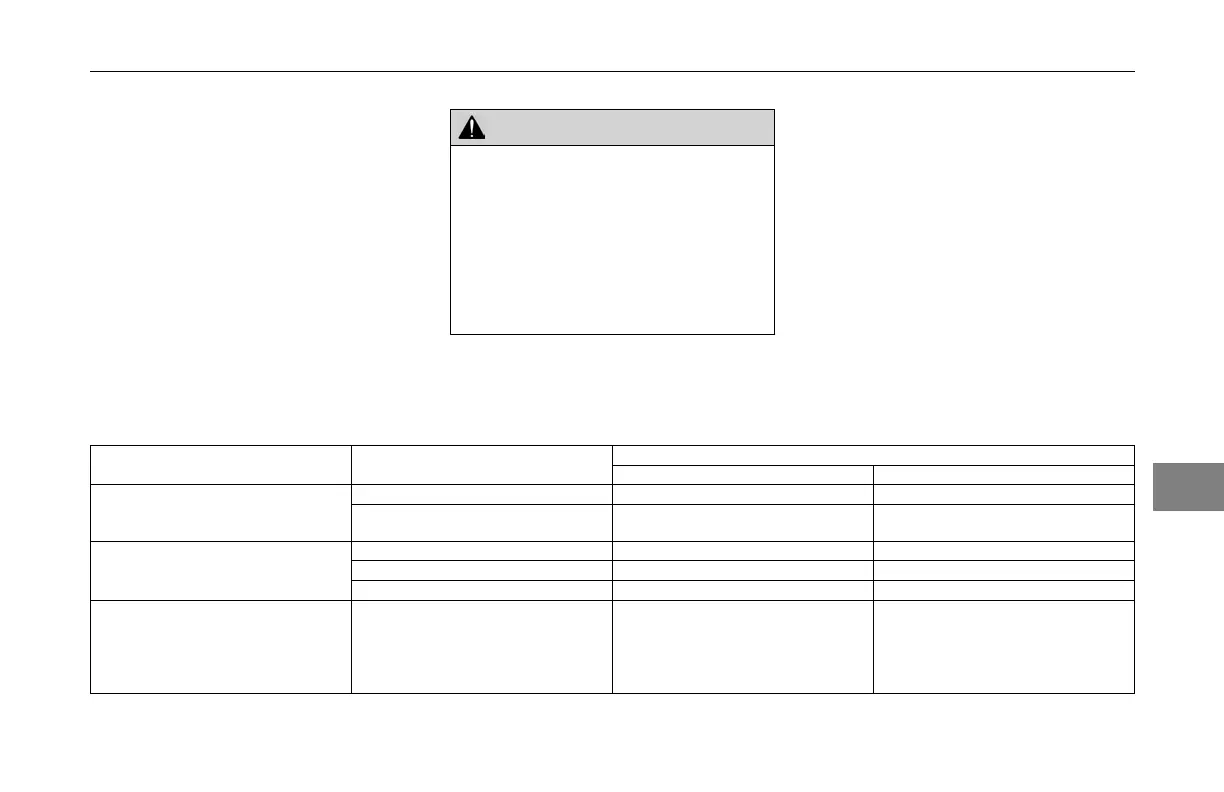

WHEEL and NUT

STUD SIZE TORQUE FOR INNER and OUTER CAP NUTS and RIM CLAMP NUTS

CONFIGURATION

Nm Lb-Ft

Steel or

Aluminum Disc-Type

Wheel; Double Cap Nut Mounting;

Standard 7/8 Radius Ball Seat

3/4-16

610-680 450-500

1-1/8-16

610-680 450-500

Heavy-Duty Steel Disc-Type Wheel;

Double Cap Nut Mounting;

15/16-12

1,020-1,220 750-900

1-1/8-16

1,020-1,220 750-900

1-3/16 Radius

Ball Seat:

1-15/16-12

1,020-1,220 750-900

Hub-Piloted Disc-Type

Wheel

w/Two Piece Flanged Cap Nuts:

Steel or Aluminum Wheel

PHP-10; Budd Uni-Mount-10;

WDH-8

M22-1.5 610-680 450-500

5

(04/13) Y53-6047–2C 5-141

Loading...

Loading...