TIRES AND WHEEL

WHEEL and NUT

CONFIGURATION

STUD SIZE TORQUE FOR INNER and OUTER CAP NUTS and RIM CLAMP NUTS

Nm Lb-Ft

Stud Backnuts

(when used) 3/4-16

240-270 175-200

1-14 240-410 175-300

Rim Clamp

Nut Torque

Cast Spoke

Wheel Assembly

1/2” Dia.

5/8” Dia.

3/4” Dia.

110-120 80-90

220-250 160-185

305-335 225-245

Threads should be clean and dry. Do

not lubricate wheel nuts or studs.

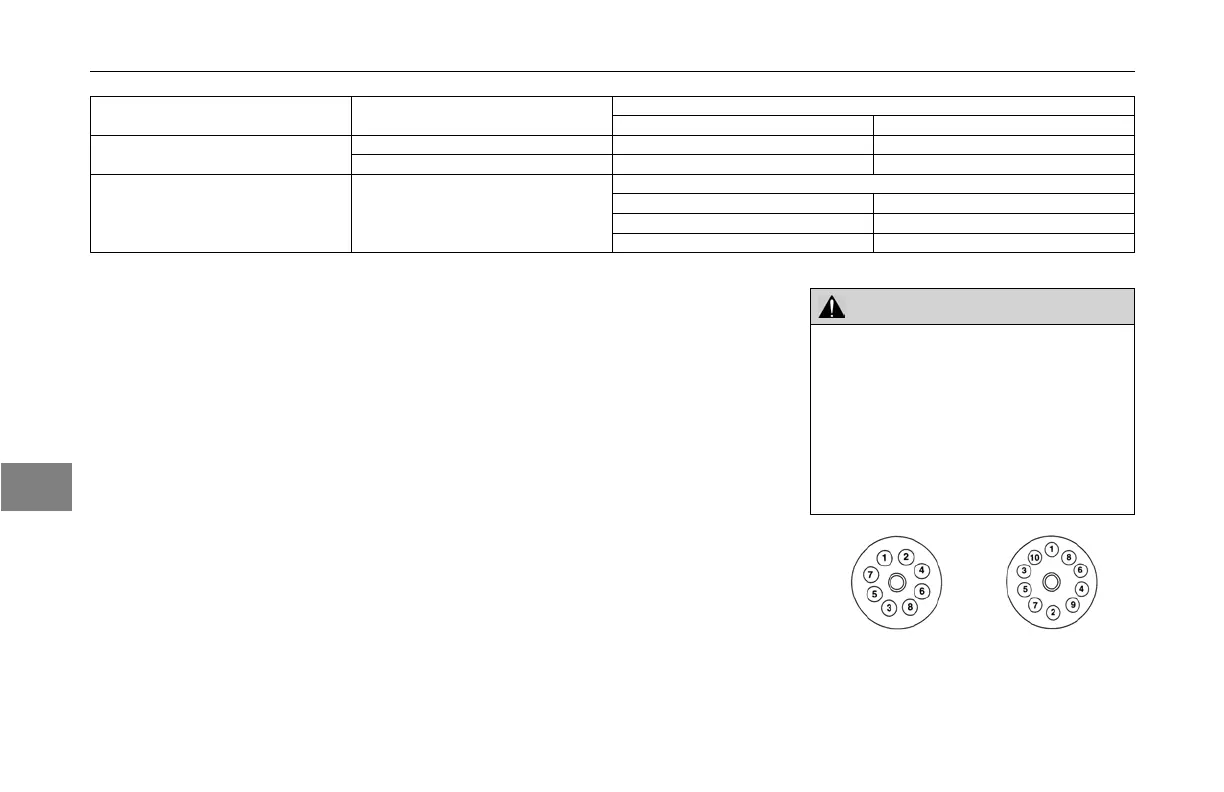

Proper Torque and Sequence

Proper wheel

torque can best be

obtained on level ground. Install lug

nuts and nger-tighten in the numerical

sequence as

shown below, see Nut

Tightening

Sequence for Hub Piloted

Disc Wheels

on page 5-142 or Nut

Tightening

Sequence for Stud Piloted

Disc Wheels

on page 5-143. This

procedure will ensure that the wheel is

drawn evenly against the hub. Torque

each nut to the torque value listed in

Wheel Cap

Nut Torque on page 5-141.

Tighten

wheel cap nuts properly. If

they are not tightened properly, wheel

nuts could eventually cause the wheel

to become loose, to fail, and/or to

come off while the vehicle is moving,

possibly causing loss of control and

may result in death, personal injury,

equipment or property damage.

WARNING!

5

Nut Tightening Sequence for Hub

Piloted Disc Wheels

5-142 Y53-6047–2C (04/13)

Loading...

Loading...