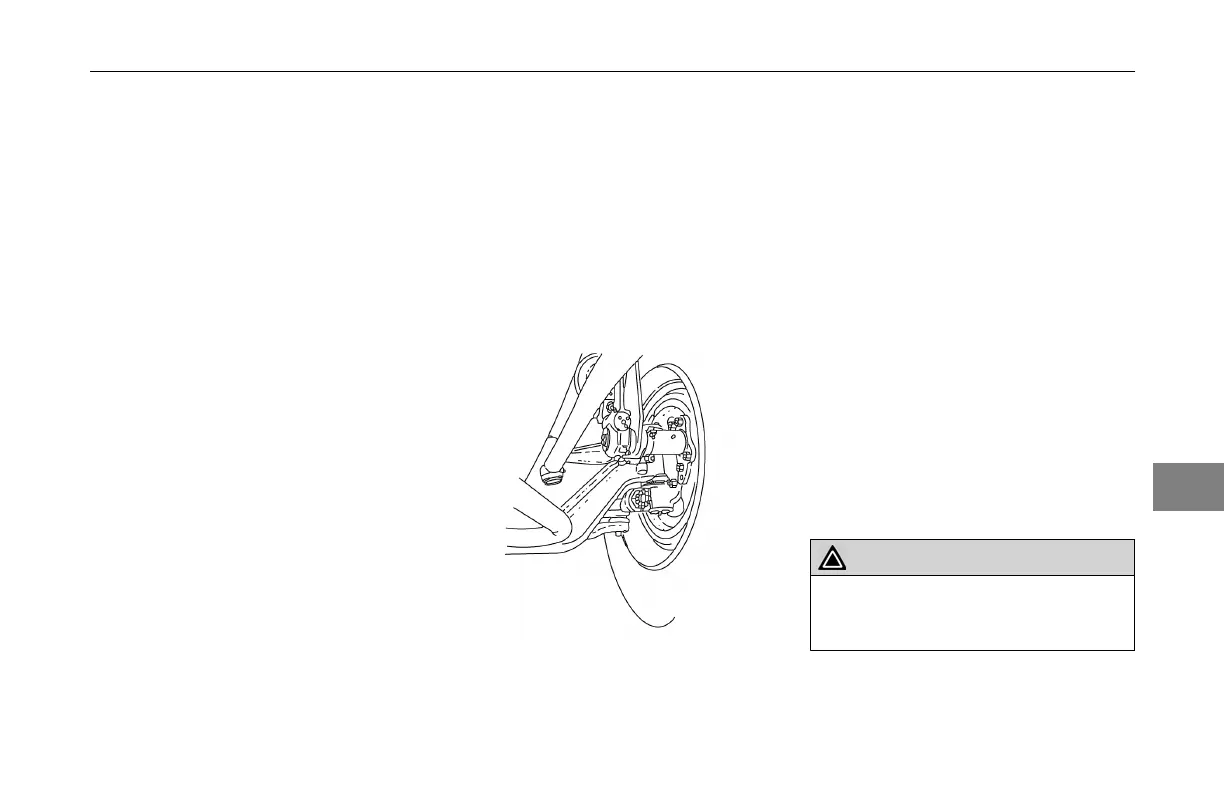

FRONT AXLE AND SUSPENSION

FRONT AXLE AND

SUSPENSION

Axle Lubrication

Change bearing lubrication when seals

are replaced, or brakes are relined.

See Preventive

Maintenance Schedule

on page

5-12.

Thoroughly clean

hubs and bearings

with solvent and a stiff bristle brush,

then dry and inspect components for

wear or damage. Re-lubricate with

approved axle lubricant.

Kingpin Lubrication

Lubricate with

approved lubricant.

Lubricate knuckle thrust bearings,

knuckle pins, and tie rod ends. See

Preventive Maintenance

Schedule

on page

5-12. Lack of lubrication

causes premature wear and hard

steering. Lubrication schedule may be

shortened if necessary.

Suspension Lubrication

Each standard

spring anchor pin

has a grease tting. Pressure

lubricate spring pins as specied. See

Preventive Maintenance

Schedule on

page 5-

12.

At regular

intervals, the spring leaves

may be lubricated with a rust-inhibiting

oil applied with a spray gun or brush.

Depending on

your suspension,

lubricate all spring pins until grease

ows out of both ends of the bushing.

Look for signs of rust or water in the

ushed grease. If a pin will not accept

grease, it should be removed, cleaned,

and inspected.

CAUTION

Do not spray the suspension with

chemical products or mineral oil; it can

cause damage to the bushings.

5

(04/13) Y53-6047–2C 5-107

Loading...

Loading...