VEHICLE RECOVERY AND SPRING BRAKES

Always secure the vehicle with wheel

chocks, chains, or other safe means to

prevent rolling before manually releas

-

ing the spring brakes. Releasing the

spring brakes on an unsecured vehicle

could lead to an accident. The vehicle

could roll, which may result in death,

personal injury, equipment or property

damage.

WARNING!

To move a vehicle immobilized by

the spring brakes due to loss of air

pressure in the brake system, perform

the following procedure:

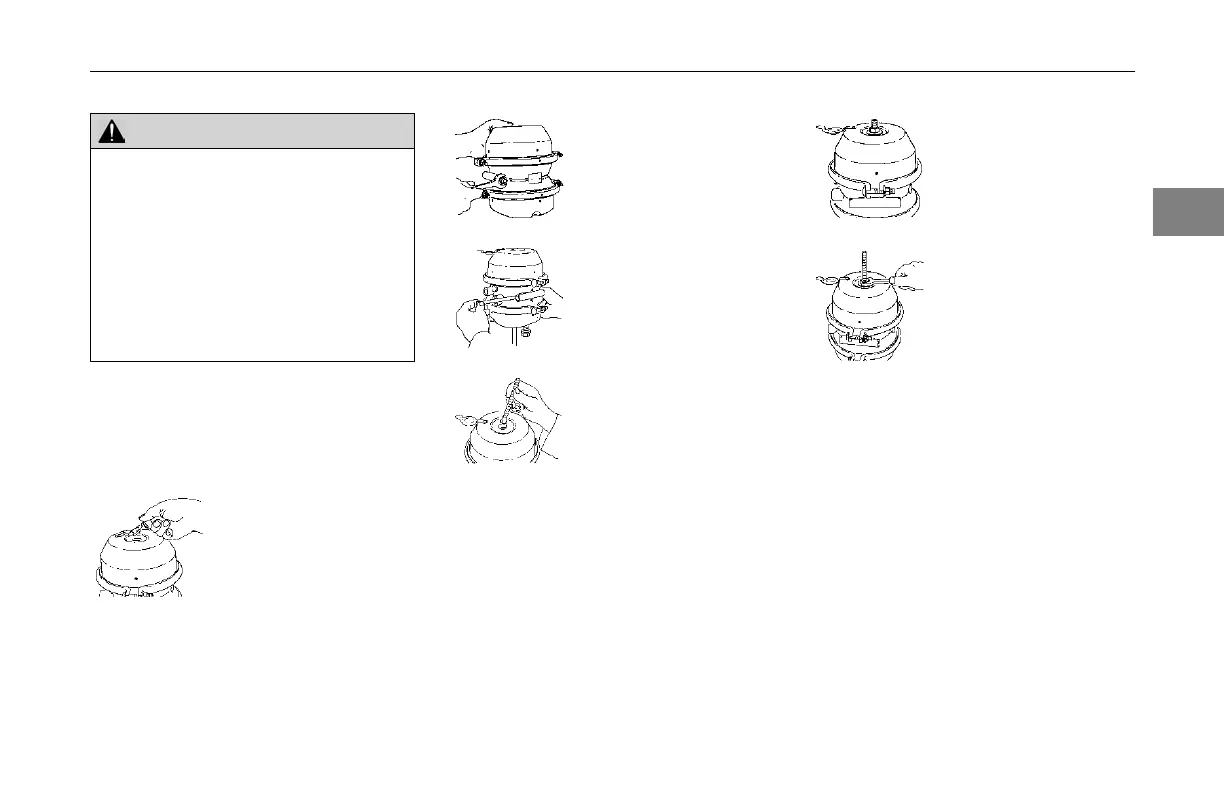

1. Remove the cap from

the spring chamber.

2. Remove the release

stud assembly from the

side pocket, and remove

the release nut and

washer from the release

stud.

3. Slide out

the release

stud.

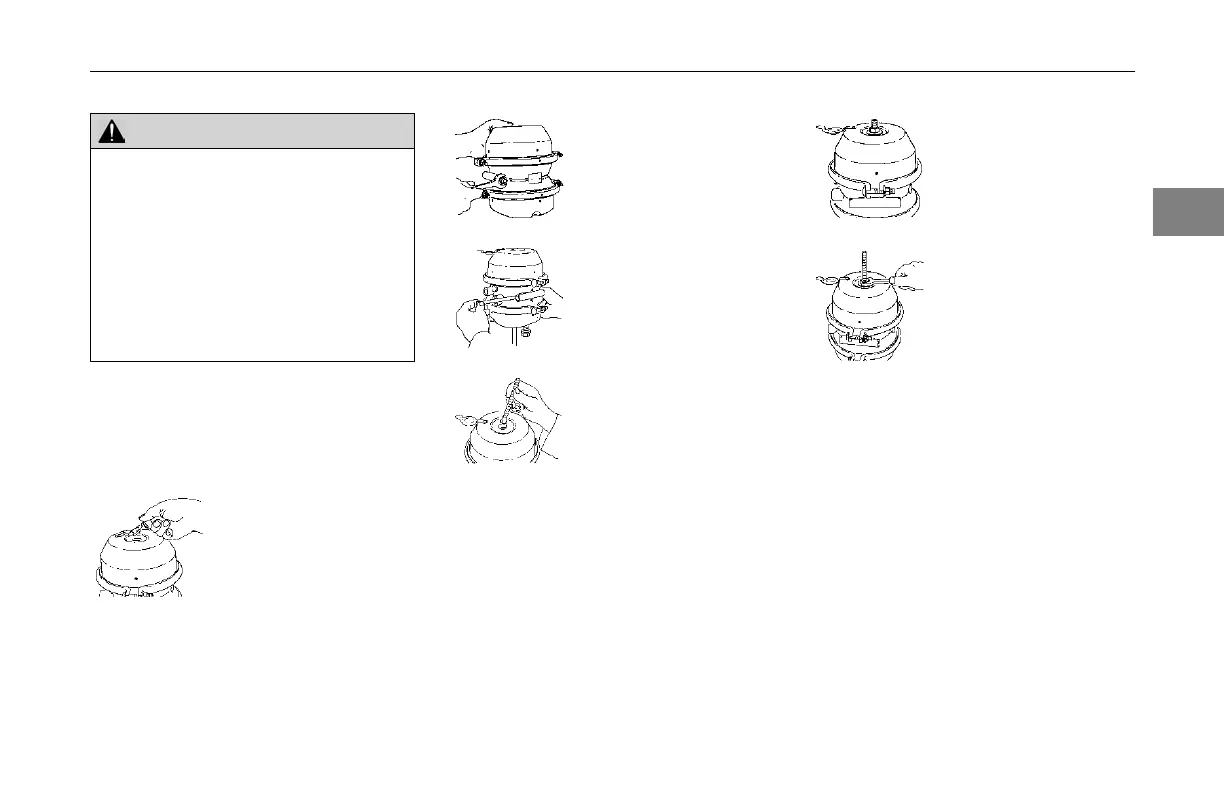

4. Insert the

release stud

through the opening in

the spring chamber

where the cap was

removed. Insert it into

the pressure plate. Turn

the release stud 1/4

turn clockwise in the

pressure plate. This

secures the cross pin

into the cross pin area of

the pressure plate and

locks it into the manual

release position.

5. Assemble the release

stud washer and nut on

the release stud.

6. With a

wrench,

turn the release stud

assembly nut until the

compression spring is

90-95 percent caged.

While doing this, check

to make sure the push

rod (adapter push

rod or service push

rod) is retracting. Do

not over-torque the

release stud assembly.

(S-Cam type maximum:

50 lb-ft, Wedge type

maximum: 30 lb-ft).

The spring brake is now

mechanically released.

2

(04/13) Y53-6047–2C 2-21

Loading...

Loading...