© 2020 Pierce Manufacturing Inc. All Rights Reserved. Scheduled Inspections / 7-3

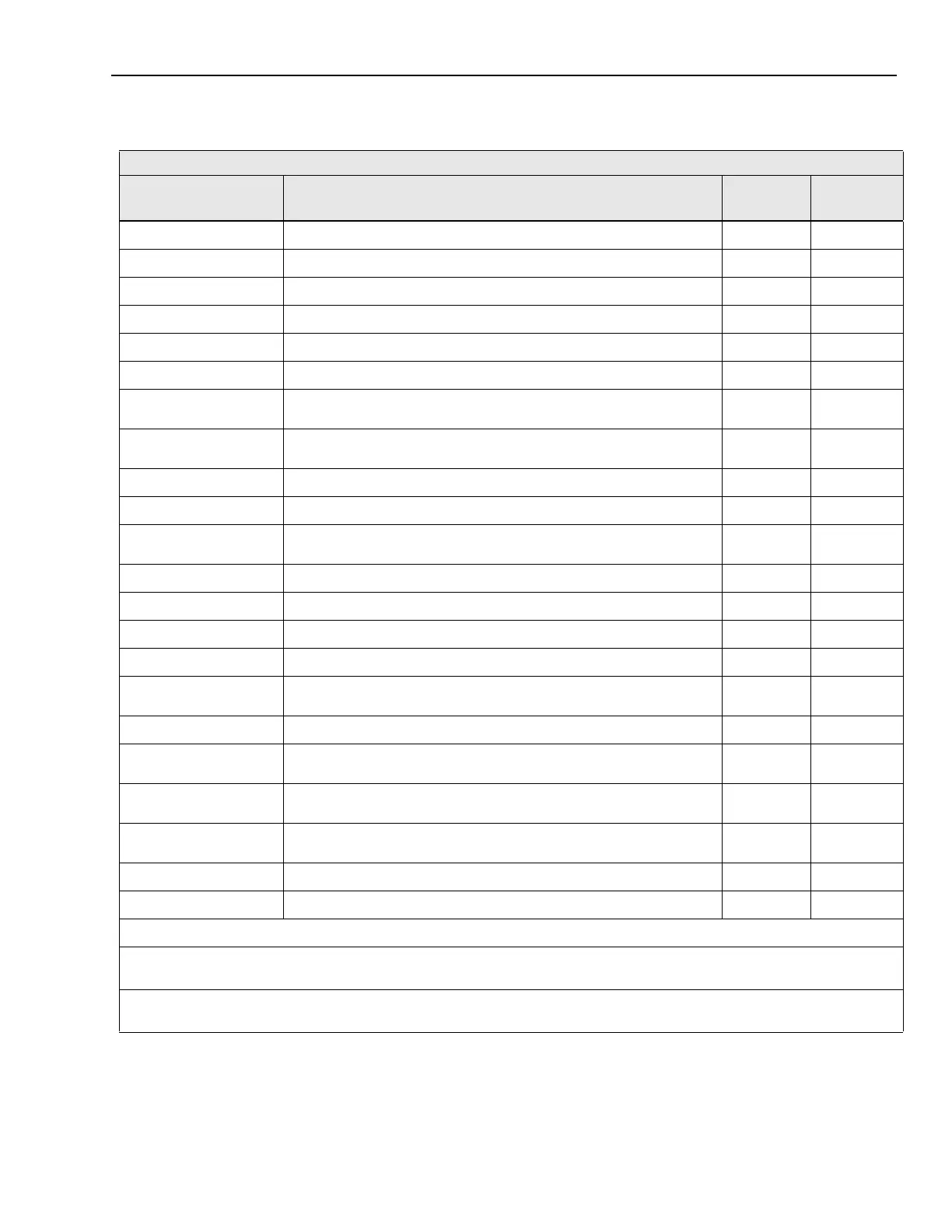

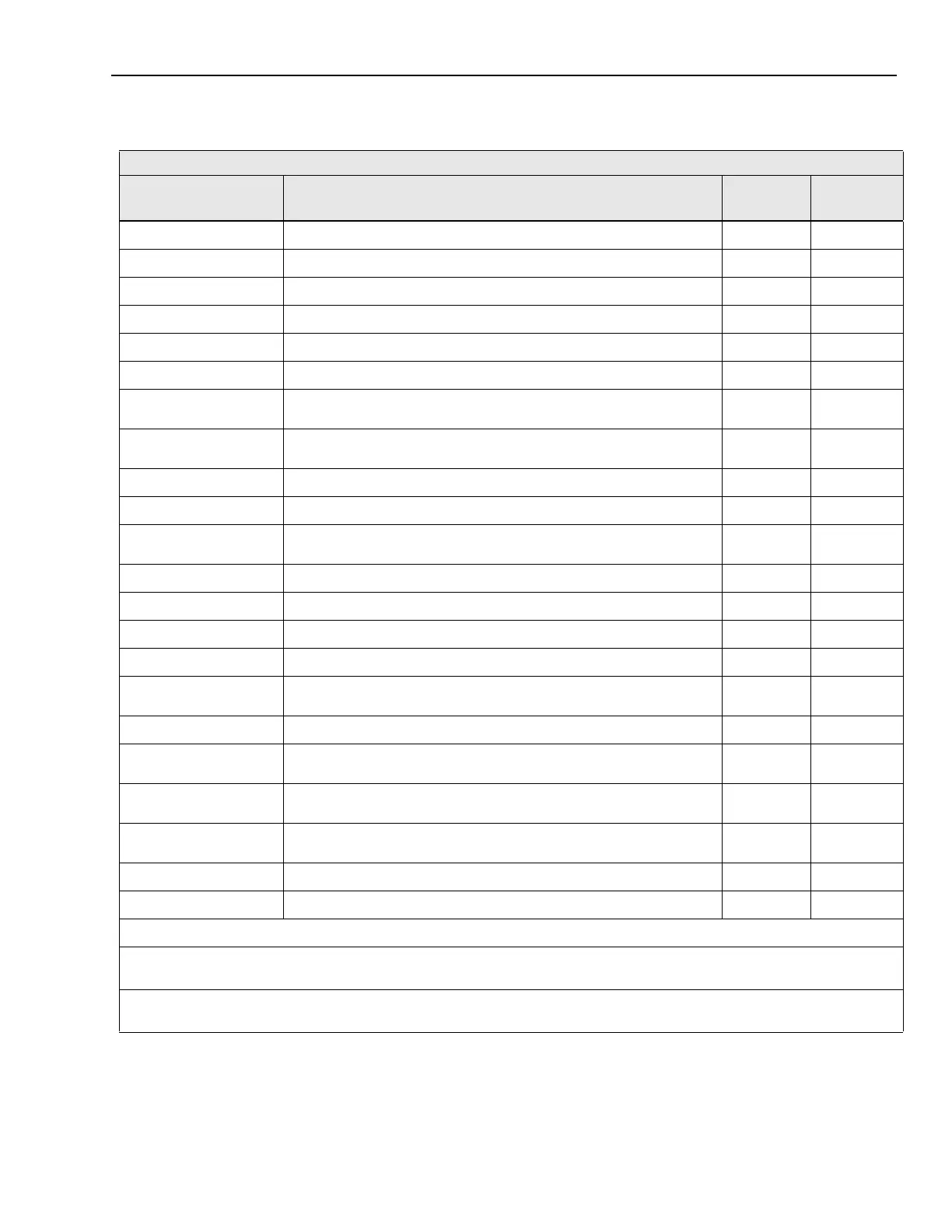

LUBRICATION AND MAINTENANCE INTERVALS

7-1.3 Weekly Inspections

Weekly Preventative Maintenance, Checks, and Services

System/Component Action

Standard

Interval

Alternate

As Indicated

Aerial Boom Support Inspect fasteners for tightness and integrity. Weekly

Air Dryer Test purge pressure. Weekly

Air Inlet Inspect engine air inlet for dirt, debris, or plugging. Weekly

Axle, Front Inspect for signs of wear, damage, or looseness. Weekly

Belts Inspect for damage and check tension. Weekly

Brake Linings Inspect for sufficient lining thickness. Weekly

Brakes Inspect all brake parts for integrity. (See “Brakes – General” on

page 6-10.)

Weekly

Cab Tilt System Check fluid level. (See “Cab Tilt System” on page 6-1 for fluid

type.)

Weekly

Driveshafts Inspect for signs of damage. Weekly

Electrical Connectors Inspect for tightness, corrosion, and integrity. Weekly

Electrical Harnesses

and Wires

Inspect for rubbing, fraying, or looseness. Weekly

Frame Fasteners Inspect for looseness, wear, or corrosion. Weekly

Fuel System Inspect for signs of damage, leaking, or chafing. Weekly

Fuel-Water Separator Check water collection bowl and drain condensate. Weekly

Mirror Hardware Inspect fasteners for tightness and integrity. Weekly

Seat Belt Assemblies Inspect for signs of damage, wear, or corrosion. (See “Seat

Belts” on page 6-5 for additional information.)

Weekly

Springs Inspect for signs of wear, cracking, or bending. Weekly

Steering Hydraulic

System

Check oil level using dipstick, sight glass, or electronic monitor.

Fill with TES-389 approved fluid.

Weekly

Steering System Inspect all steering parts for integrity. (See “Steering” on

page 6-29 for additional information.)

Weekly

Suspension Hangers

and Shackles

Inspect for signs of wear, corrosion, or damage. Weekly

Tires Inspect tread depth and check for damage. Weekly

Wiper Blades Clean wiper blades. Weekly

Comments or Additional Items

Loading...

Loading...