813

813

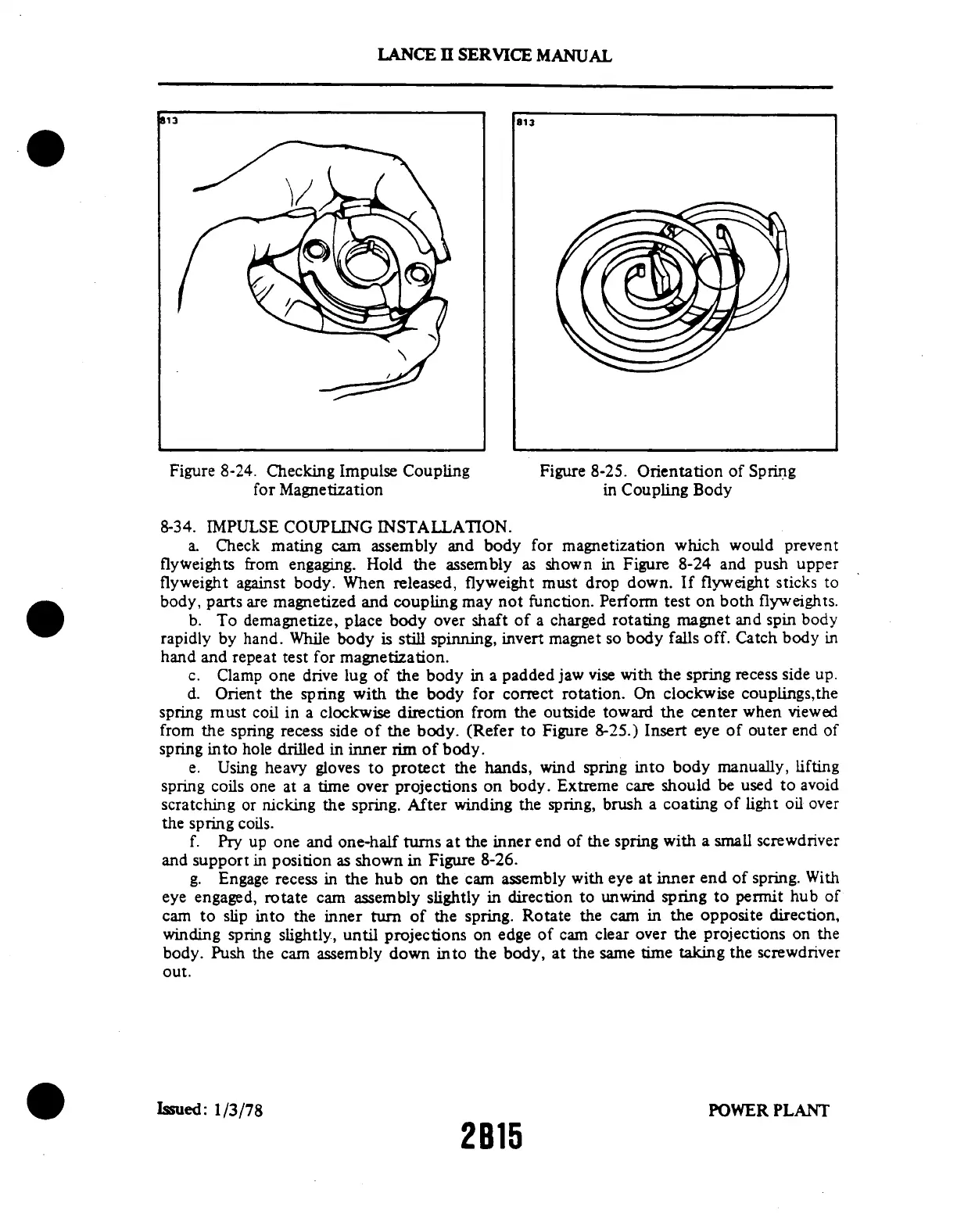

Figure 8-24. Checking

Impulse Coupling Figure

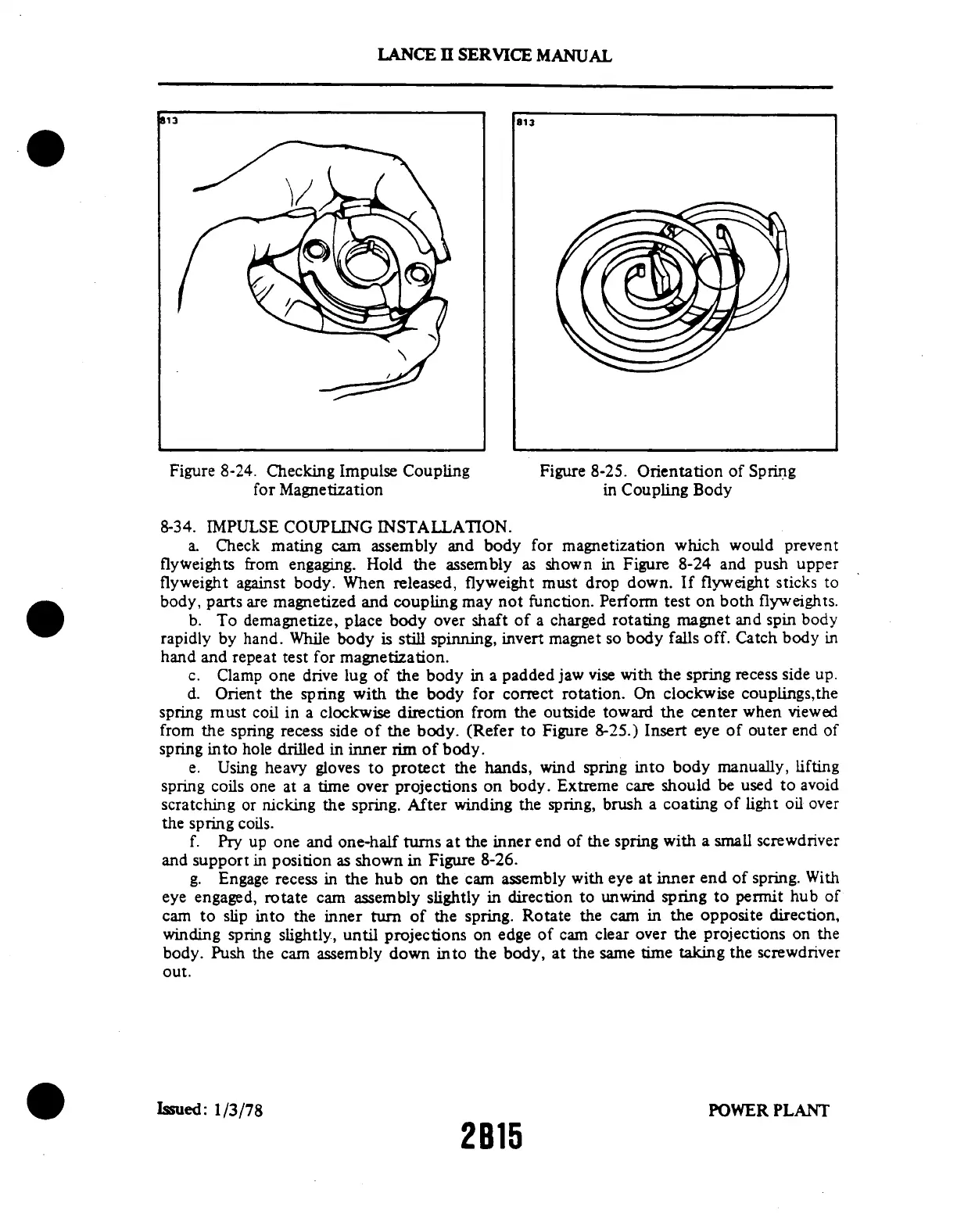

8-25. Orientation of Spring

for Magnetization in Coupling Body

8-34. IMPULSE COUPLING INSTALLATION.

a.

Check mating cam assembly and body

for magnetization which would

prevent

flyweights

from engaging.

Hold the assembly

as shown

in Figure 8-24 and

push upper

flyweight against

body. When released,

flyweight

must drop down. If

flyweight sticks

to

body,

parts are magnetized

and coupling

may not function.

Perform test on both

flyweights.

b. To demagnetize, place

body over shaft of a charged rotating

magnet and spin body

rapidly by hand. While body is still

spinning, invert magnet so body falls

off. Catch body in

hand and repeat test for magnetization.

c.

Clamp one drive lug of the body in

a padded jaw vise with the spring recess

side up.

d.

Orient the spring with the body for

correct rotation. On clockwise couplings,the

spring must coil in a clockwise

direction from the outside toward

the center when viewed

from the spring

recess side of the body. (Refer to

Figure 8-25.) Insert eye of outer end

of

spring into hole drilled

in inner rim

of body.

e. Using

heavy gloves to

protect the hands,

wind spring into

body manually, lifting

spring

coils one at a

time over projections

on body. Extreme

care should be

used to avoid

scratching or

nicking the spring.

After winding the

spring, brush a coating

of light oil over

the spring coils.

f. Pry

up one and one-half

turns at the inner

end of the spring

with a small screwdriver

and support

in position as

shown in Figure 8-26.

g. Engage recess

in the hub on the

cam assembly with

eye at inner end

of spring. With

eye engaged, rotate

cam assembly slightly in direction to

unwind spring to permit hub of

cam to slip

into the inner turn

of the spring.

Rotate the cam in

the opposite direction,

winding spring slightly, until projections on edge of cam clear over the projections on the

body. Push

the cam assembly

down into the body,

at the same time

taking the screwdriver

out.

Issued:

1/3/78

POWER

PLANT

2B15

LANCE

II SERVICE

MANUAL

Loading...

Loading...