7.2.1.1 General cleanliness and handling

The adapter has to be calibrated in Planmeca PlanMill 50 S milling units

before the first use to ensure an optimal positioning of the DESS system.

Therefore the following aspects must be considered:

• Cleanliness of the blank adapter (milling unit) and of the DESS adapter

• General Cleanliness

• No damages in the bearing surface

• The milling unit and its zero-point must be set correctly

• Always clamp the adapter in the same position

• Screw connections

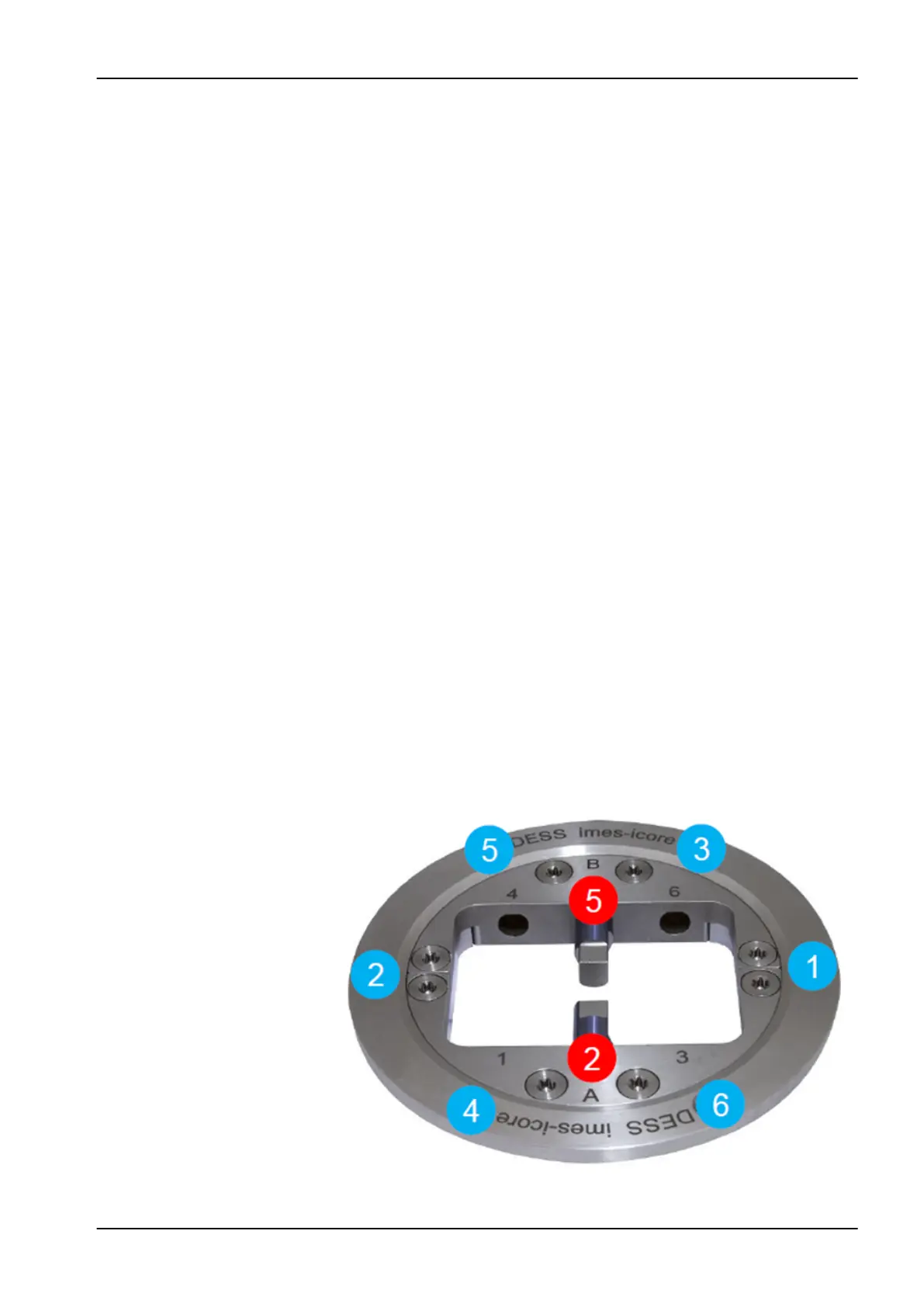

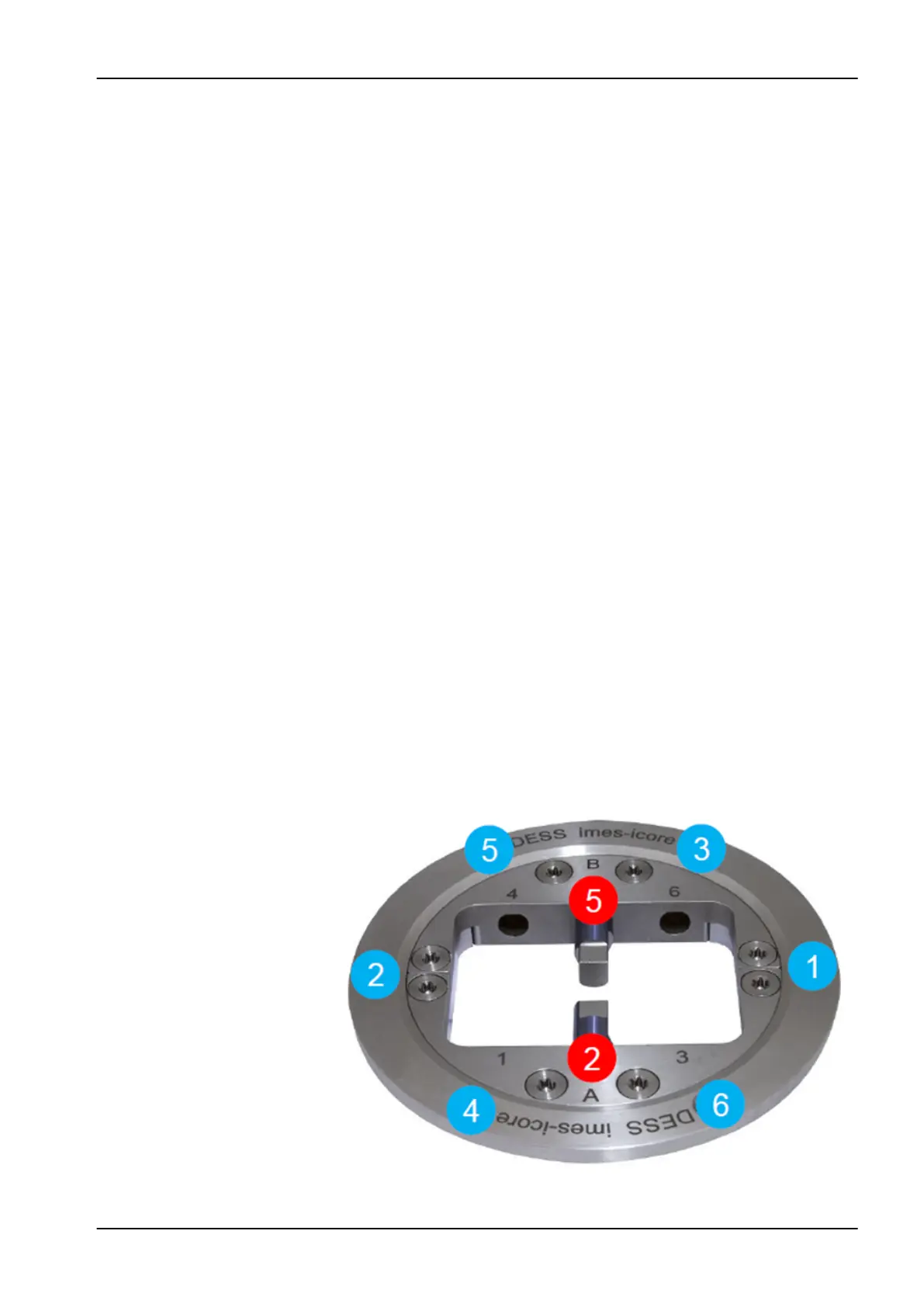

• The 6 screws should always be tightened in the same order for a

reproducible positioning

• Only screw the 6 countersunk screws loosely at first

• Afterwards tighten the screws crosswise (always in the same

order)

7.2.1.2 Preparing adapter for test milling

NOTE

Please follow directions on general cleanliness and handling.

• The two test pins, available from your local premilled blank supplier, are

thoroughly inserted into the middle positions (2 + 5), pushed in to the

limit, and firmly clamped with the clamping screw by using a torque

wrench.

• The DESS adapter is then fixed into the clean milling unit reception. The

screws should always be screwed in loosely at first and tightened

afterwards in the same order, 1 - 6.

• The test pins are milled directly on the milling unit with the scripted test

program available from your local dealer. A 2mm metal tool (T2) is

required for the milling process.

7 Adapters

User's manual Planmeca PlanMill 50 S 35

Loading...

Loading...