7.19

Shocks

7

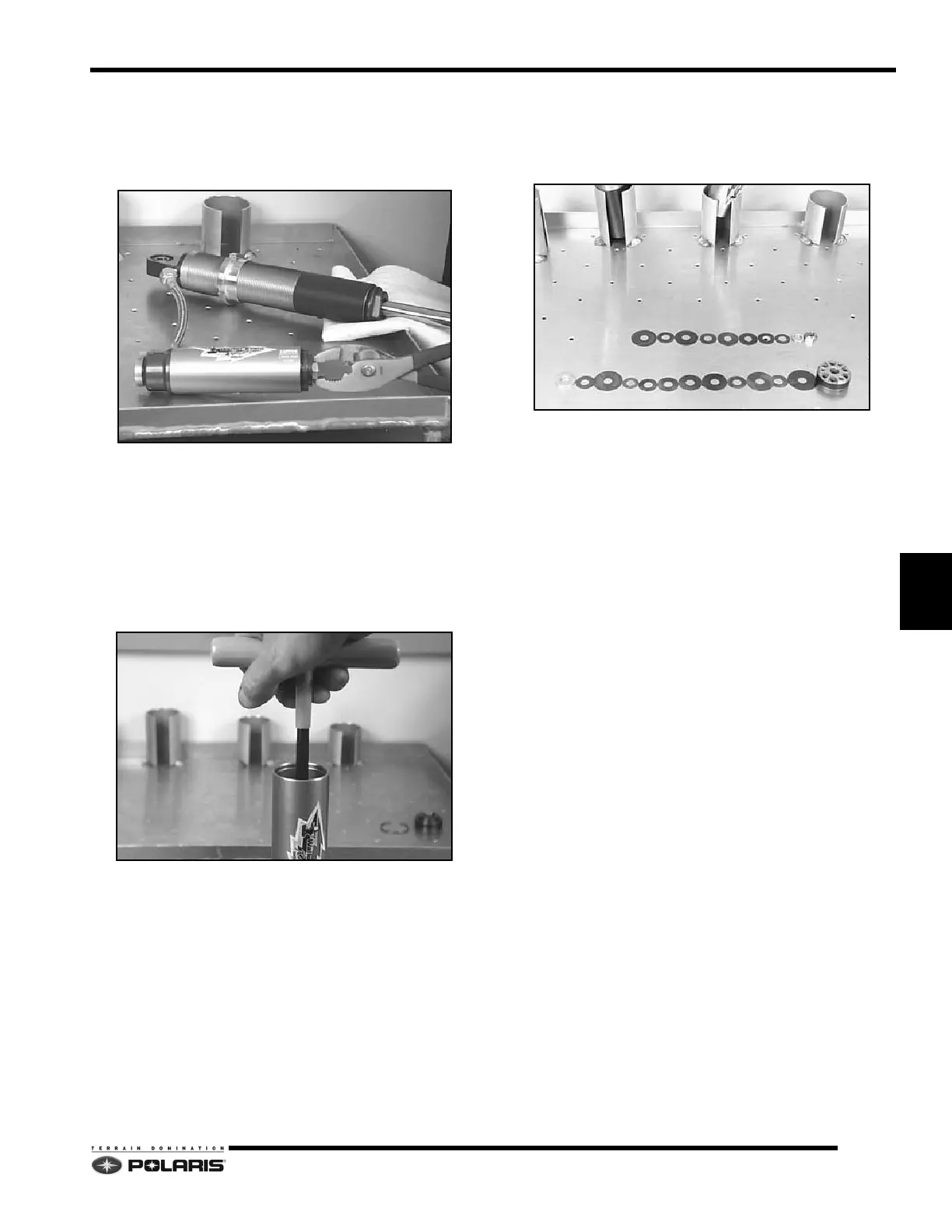

4. Press the end cap into the reservoir to access the

snap ring.

5. Remove the snap ring, then remove the cap from the

bo

dy.

6. Place the shock lower eyelet in a vise.

7. Loosen and remove the bearing cap from the shock.

8. Remove the used oil from the shock body.

NOTE: Insert the IFP tool (PN PS-45908) and cycle the

int

ernal floating piston (IFP) a few times to purge the

shock oil from the reservoir.

9. Remove the IFP from the reservoir with the IFP tool

(

PN PS-45908).

10. Clean and inspect ALL parts and replace worn out

pa

rts if needed.

IMPORTANT: Seal kits are available and should be

inst

alled at this time if seals or o-rings are damaged or

worn.

11. Place the shock rod in a vise so that the threaded part

is fac

ing upward.

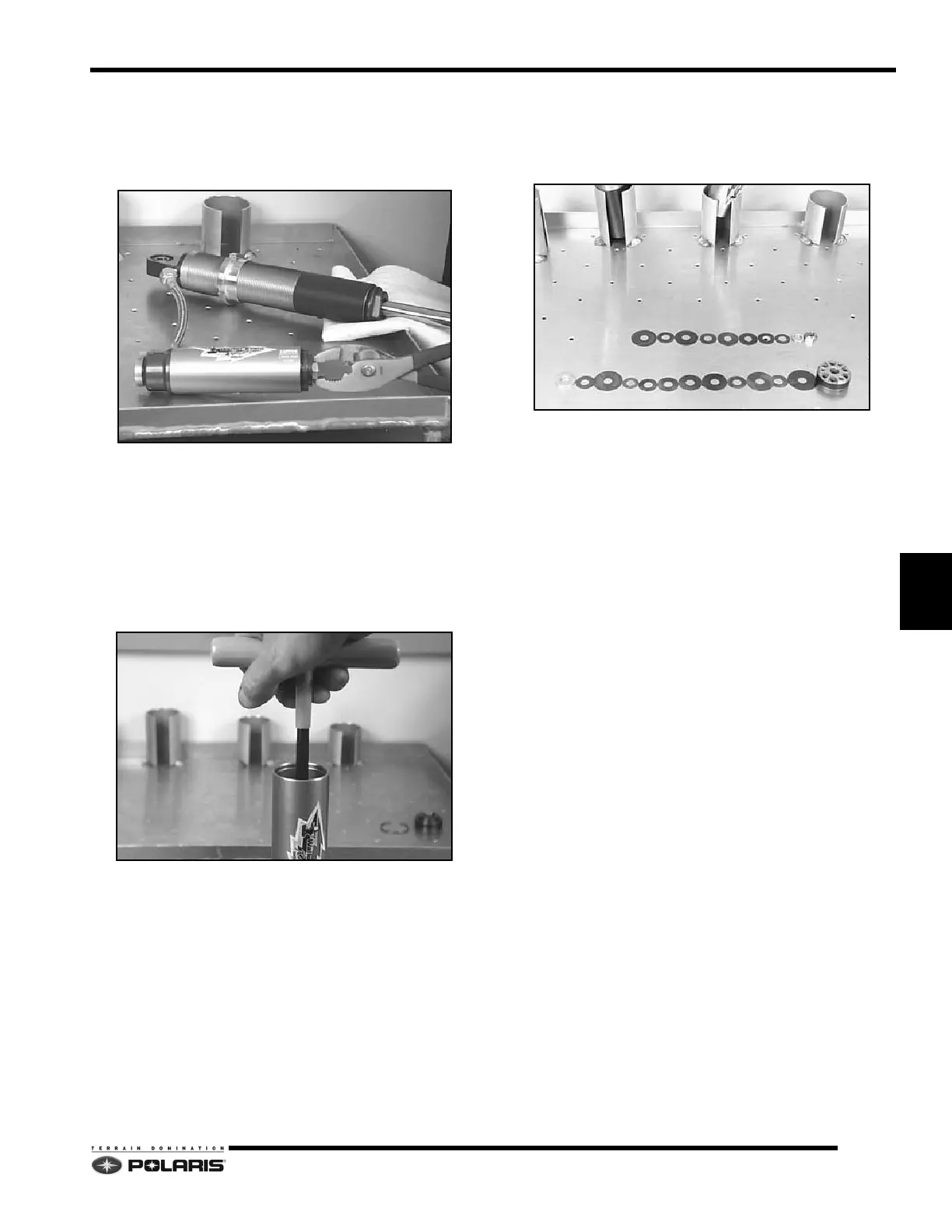

12. Place the valve stack on a clean shop towel in order

of re

moval.

NOTE: Place the valve stack on a clean shop towel in

ca

se you have to move them. This will also help when

assembling them back onto the shock rod.

13. Inspect the valves for kinks, waves, pits or foreign

ma

terial.

14. Inspect the piston wear band and replace if damaged

or

worn.

Loading...

Loading...