7.32

Shocks

FOX™ PS-5 ASSEMBLY

1. Thoroughly clean all of the components with solvent

and allow to air dry. Discard all used wear bands and

o-rings.

NOTE: The PS-5 rebuild kit (PN: 1500611) will supply

a

ll of the required o-rings, wear bands and a u-cup

seal.

Lubricate all components with new shock oil prior to

as

sembly.

2. Thoroughly clean the FIST scraper, bearing

ass

embly, and piston assembly with solvent. Dry with

compressed air. If compressed air is not available, dry

parts using clean, lint free paper towels and let sit in

a well-ventilated area, to allow the remaining solvent

to evaporate.

3. Install the new, well lubricat

ed, o-ring into the FIST

scraper. Check to make sure the seal is properly

seated, and is not twisted. If a tool is required to aid

in proper seating of o-ring, use the non-writing end of

a pen, or a similar soft, blunt object, to push it in.

4. Install new, well lubricated, o-rings into the bearing

h

ousing. Correct placement of the shaft seal o-ring is

in the groove next to the DU bushing. Check to make

sure the seals are properly seated, and are not

twisted. If a tool is required to aid in proper seating of

o-ring, use the non-writing end of a pen, or a similar

soft, blunt object, to push it in.

5. Install the new u-cup seal into bearing. The u-cup seal

sh

ould be installed so the cupped end is facing the DU

bushing inside of bearing. Check to make sure seal is

properly seated. If a tool is required to aid in proper

seating of U-cup seal, use the non-writing end of a

pen, or a similar soft, blunt object, to push it in.

6. Install FIST scraper into housing

. The stepped side of

the FIST scraper should be visible.

7. Using a small pair of snap-ring pliers,

install the snap-

ring into the bearing housing. Check for proper

orientation of the snap ring. The flat side of the snap-

ring should be visible. Check to make sure the snap-

ring is properly seated.

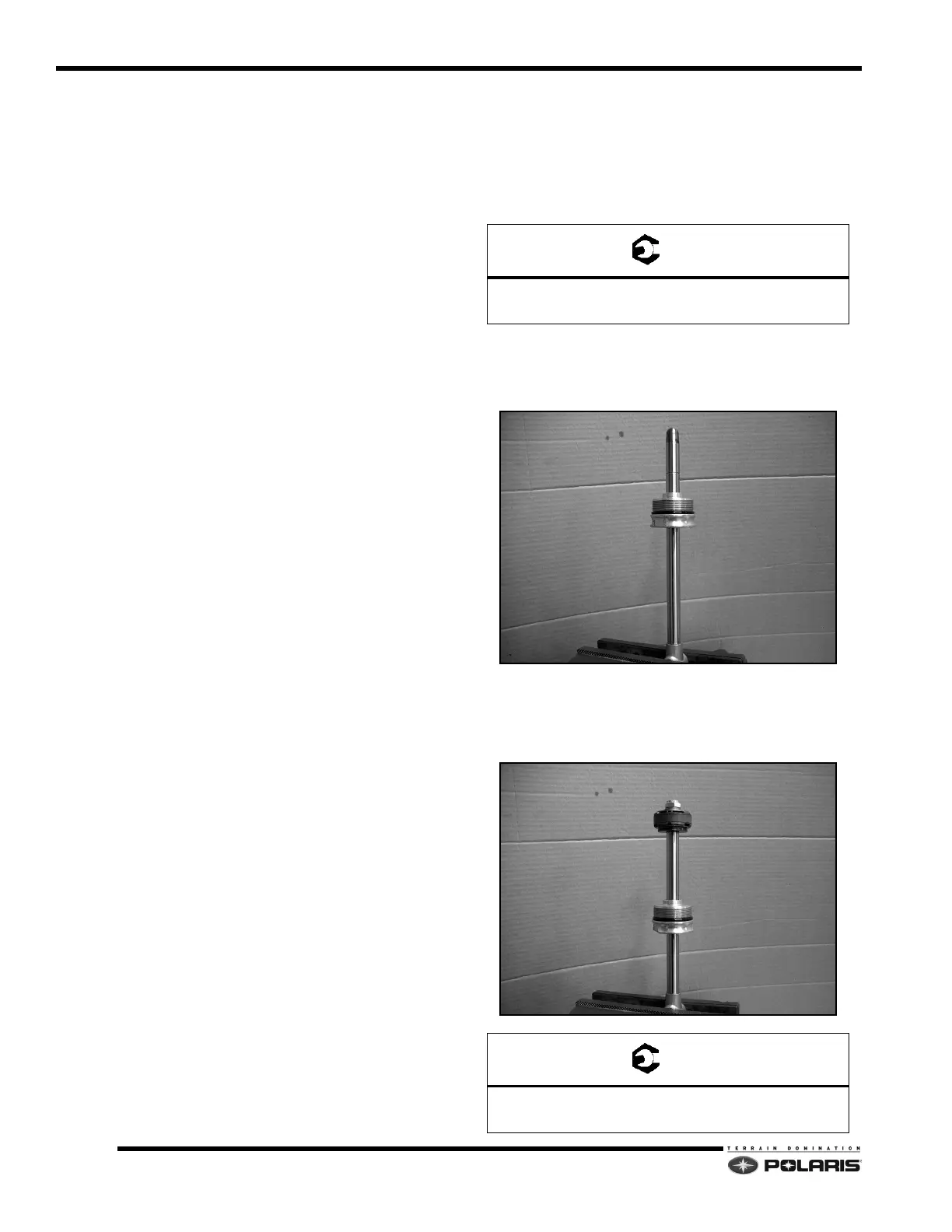

8. Place the shock rod eyelet in a bench vise with the

th

readed end up.

NOTE: If shock rod eyelet was serviced, install eyelet

on shoc

k rod and torque to specification. Use shock

rod holding tool (2871352) to secure rod.

9. Install shock rod seal protector onto shock rod

(2

201639). Lubricate the shock rod with shock oil.

10. Install the bearing assembly onto the shock shaft.

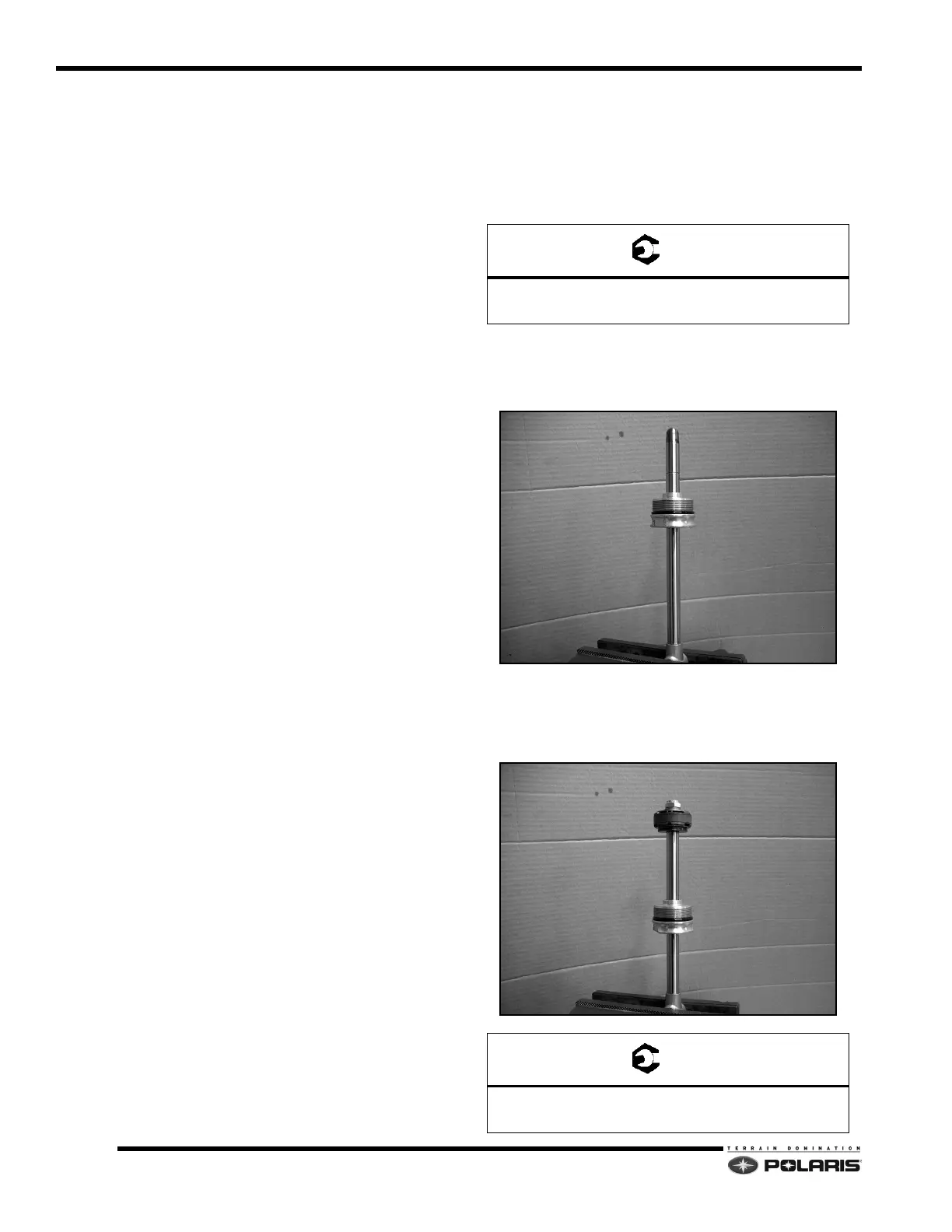

11. Remove the shock rod seal protector. Install the

piston valve assemb

ly onto the shock rod.

12. Install washer and new lock nut. Torque lock nut to

s

pecification.

Shock Body Eyelet

50 ft-lbs (68 Nm)

Piston Valve Lock Nut

18 ft-lbs (24 Nm)

Loading...

Loading...