7.21

Shocks

7

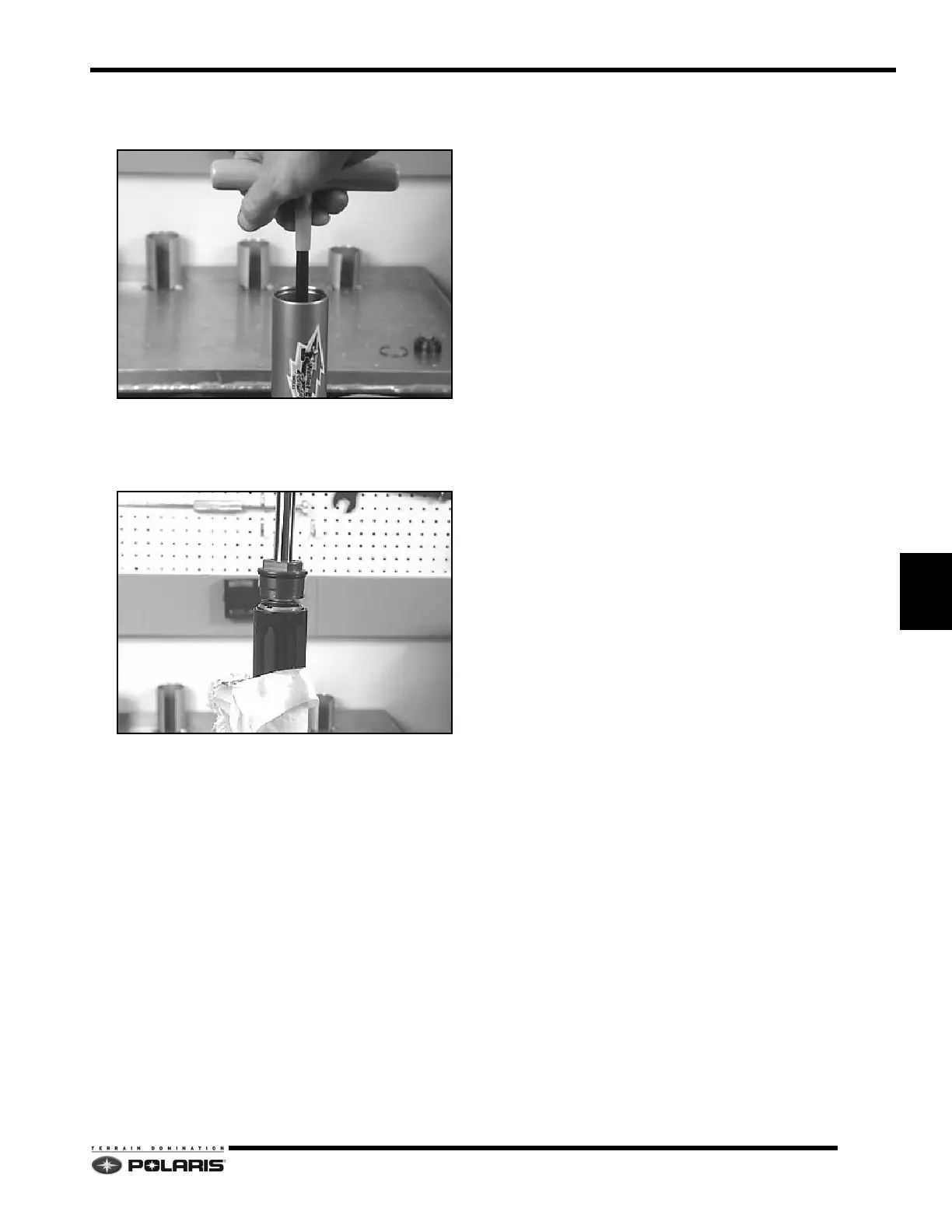

12. Set the IFP so it is approximately 1/8 from the bottom

of the reservoir. Install the bleed screw.

13. With the cylinder head assembly pushed down

ag

ainst the valve piston, dip the piston assembly in

shock oil.

14. Fill the shock body with oil to

the bottom of the threads.

Carefully insert the piston rod and valve assembly into

the cylinder.

• Slightly oscillate the piston rod to

allow the piston

to enter the shock body bore as it purges the air

out

• Slight up and down movement may be required to

allow all the air

to pass through the piston

assembly.

15. Slowly push the piston rod and assembly into the

sho

ck body until the threads can be engaged.

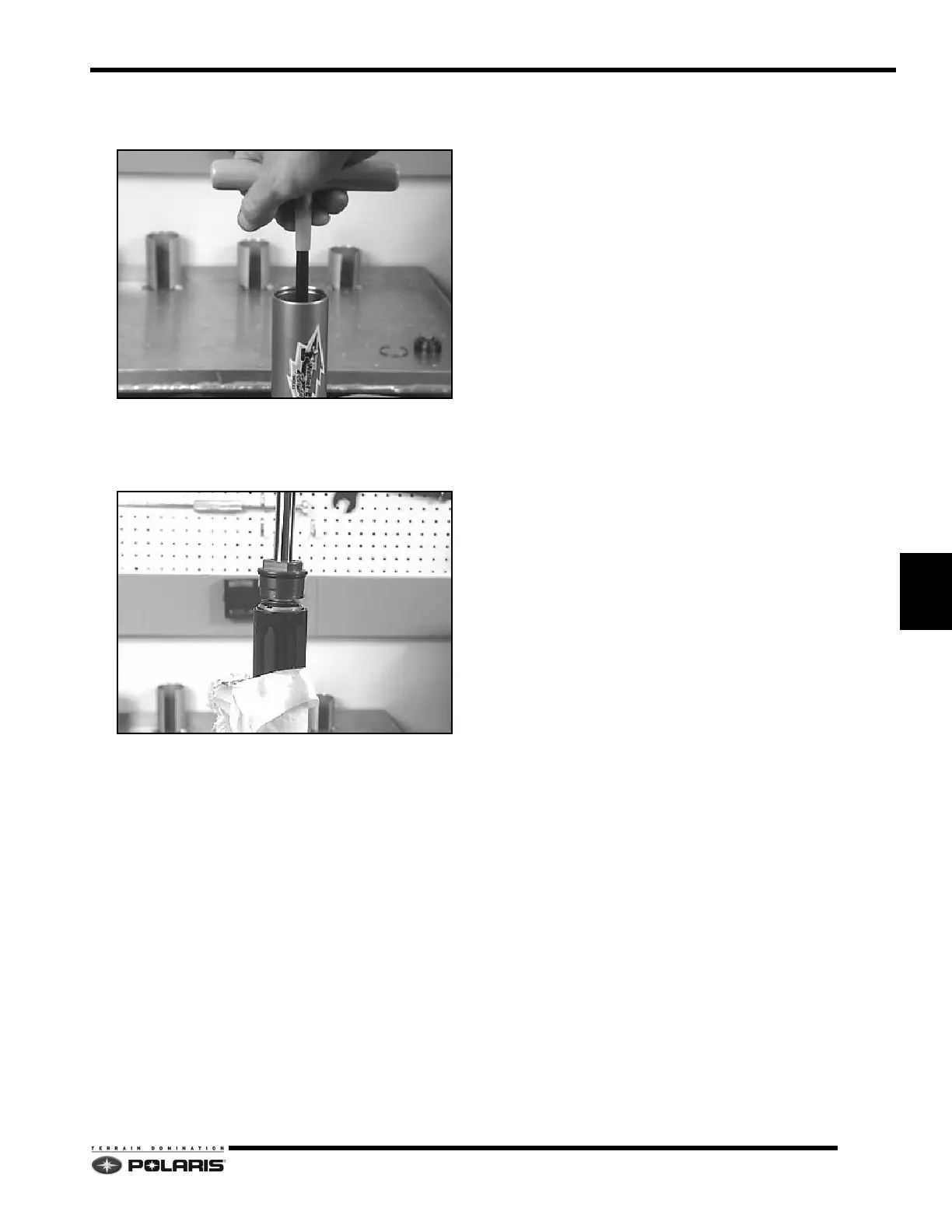

NOTE: During installation, some shock oil will over

f

low. Wrap a shop cloth around the shock body to

catch any oil overflow.

IMPORTANT: Fast installation of the piston rod and

as

sembly may displace the internal floating piston

(IFP) from its original position. Performance issues

will be a result if the IFP is not in its specified position.

16. Tighten the cylinder head onto the shock body.

17. Verify the IFP is set at the specified depth. If not, verify

th

ere is oil on top of the IFP, then open the bleed

screw.

18. Set the IFP to specification, then close the bleed

screw.

19. Pour out any remaining shock oil from the reservoir.

20. Install the cap making sure the o-ring does not flip-

o

ver. Install the snap ring.

21. Charge the shock to the specified pressure.

22. Clean the shock of all oil reside and check for any

leaks.

23. Install button screw onto the reservoir cap.

Loading...

Loading...