78

Chapter 8 Maintenance and repair

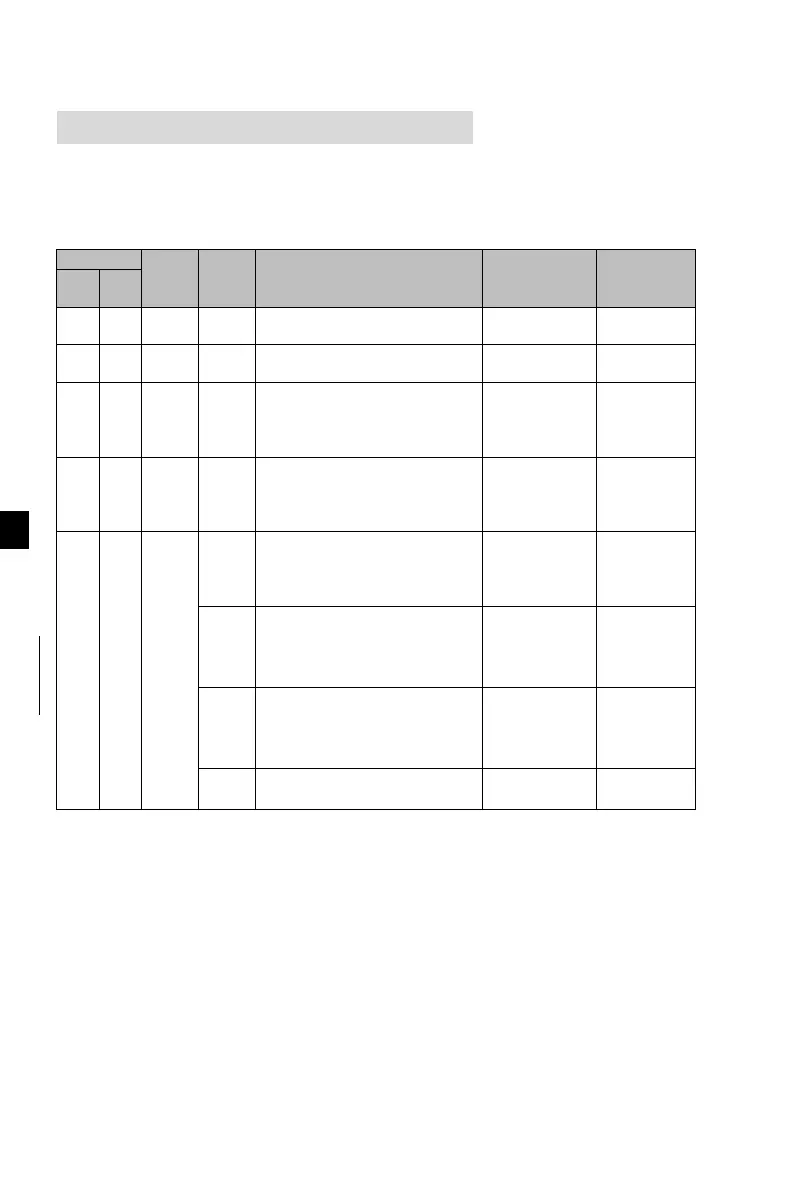

8-1.Inspection and maintenance

During normal use of the inverter, in addition to routine inspections, the regular inspections

are required (e.g. the overhaul or the specified interval, and the interval shall not exceed 6

months), please refer to the following table to implement the preventive measures.

Whether display is abnormal or

not

Whether abnormal noise or

vibration exists or not

Visually and

audibly check

Temperature, humidity,

dust, harmful gas.

Visually check

with smelling

and feeling

Whether input/output voltage

is abnormal or not

Test R, S, T and

U, V, W

terminals

As per

standard

specifications

Whether these phenomenon of

loose fastenings, overheat,

discharging, much dust, or

blocked air duct exist or not

Visually check,

tighten and clean

Whether appearance is abnormal

or not

Whether they are loose or not

If screws or bolts are loose or not

"√" means routine or regular check to be needed

Do not disassemble or shake the device gratuitously during check, and never unplug the

connectors, otherwise the system will not run or will enter into fault state and lead to component

failure or even damage to the main switching device such as IGBT module.

The different instruments may come to different measurement results when measuring. It is

recommended that the pointer voltmeter shall be used for measuring input voltage, the rectifier

voltmeter for output voltage, the clamp-on ammeter for input current and output current, and the

electric wattmeter for power.

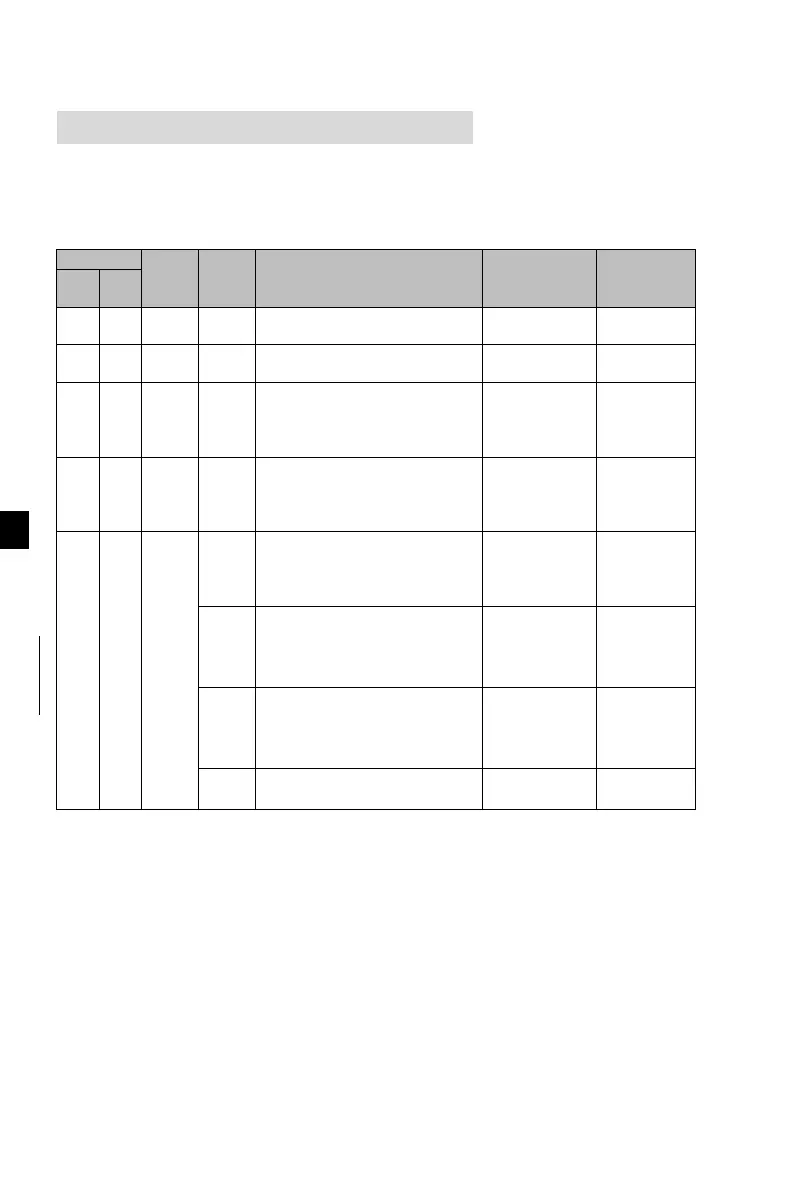

8-2.Parts for regular replacement

To ensure the reliable operation of inverter, in addition to regular care and maintenance, some

internal mechanical wear parts(including cooling fan, filtering capacitor of main circuit for energy

storage and exchange, and printed circuit board) shall be regularly replaced. Use and replacement

for such parts shall follow the provisions of below table, also depend on the specific application

environment, load and current status of inverter.

Loading...

Loading...