-63-

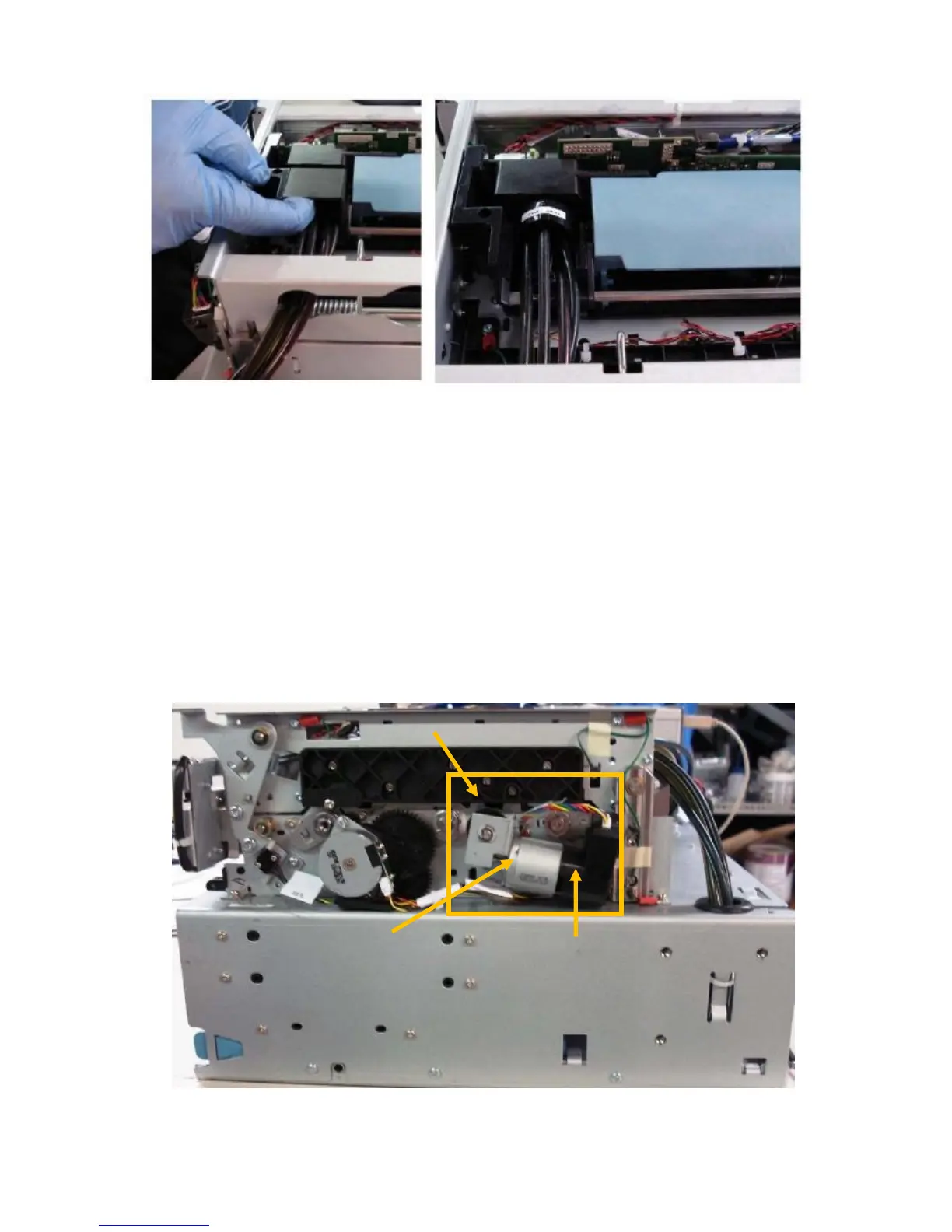

Picture of Remove Fluidic Coupling Covers

2. Visually inspect each tubing connection point for leaks. If leaks are found, escalate to a

technician for troubleshooting.

3. Follow the exposed length of each tube and visually inspect each ink tube for inks or

pinches in the tubing. Undo the irregularity to allow ink to flow freely. Escalate to a

technician if leaks result.

4. Re-install the fluidic coupling covers.

5. Re-install any housing removed to access this area.

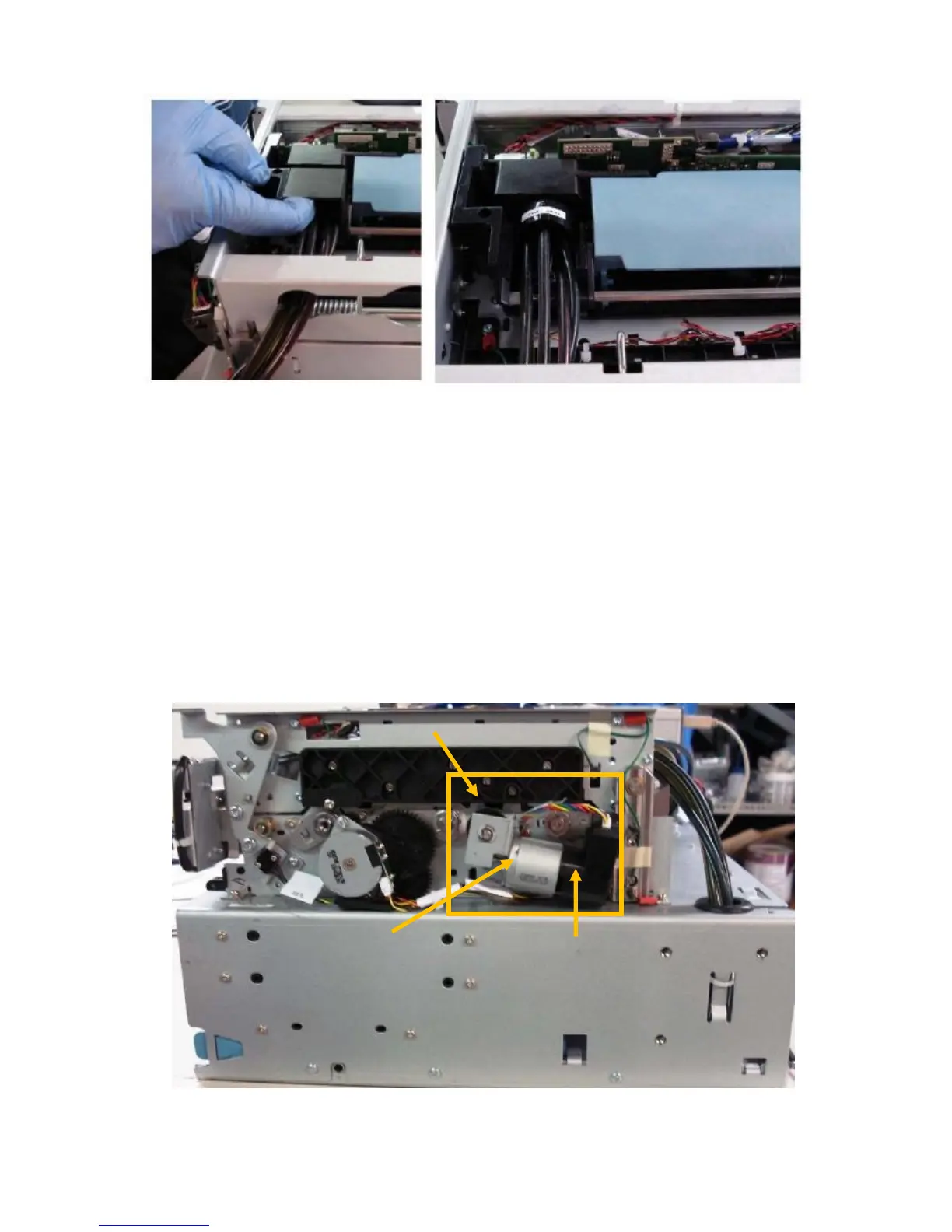

Lifter Motor – Gear Inspection and Encoder Cleaning

The lift motor gear, on the right side of the unit, must be inspected every month.

Loading...

Loading...