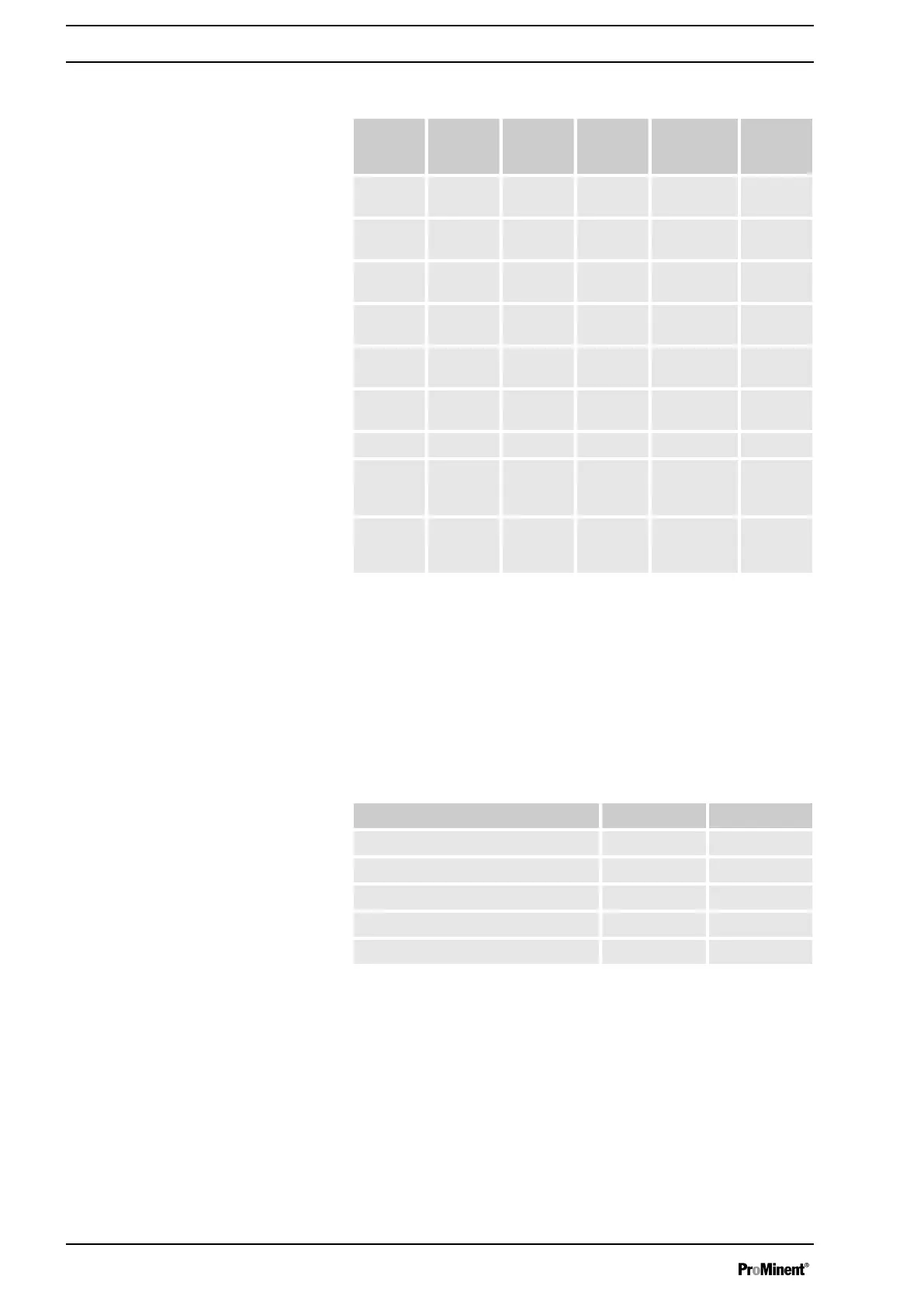

17.4 Material specifications

Design Dosing

head

Suction/

pressure

connector

Ball seat Seals Balls

PPE Polypro‐

pylene

Polypro‐

pylene

EPDM EPDM Ceramic

PPB Polypro‐

pylene

Polypro‐

pylene

FKM FKM Ceramic

PPT Polypro‐

pylene

Polypro‐

pylene

PVDF PTFE Ceramic

NPE Clear

acrylic

PVC EPDM EPDM Ceramic

NPB Clear

acrylic

PVC FKM FKM Ceramic

NPT Clear

acrylic

PVC PVDF PTFE Ceramic

PVT PVDF PVDF PVDF PTFE Ceramic

TTT PTFE

with

carbon

PTFE

with

carbon

Ceramic PTFE Ceramic

SST Stainless

steel

1.4404

Stainless

steel

1.4404

Ceramic PTFE Ceramic

Self-bleeding design only in material versions PP and NP with a valve

spring made of Hastelloy C and a PVDF valve insert.

Diaphragm: with PTFE coating.

FKM = fluorine rubber

Housing parts: polyphenylene ether (PPE with fibreglass)

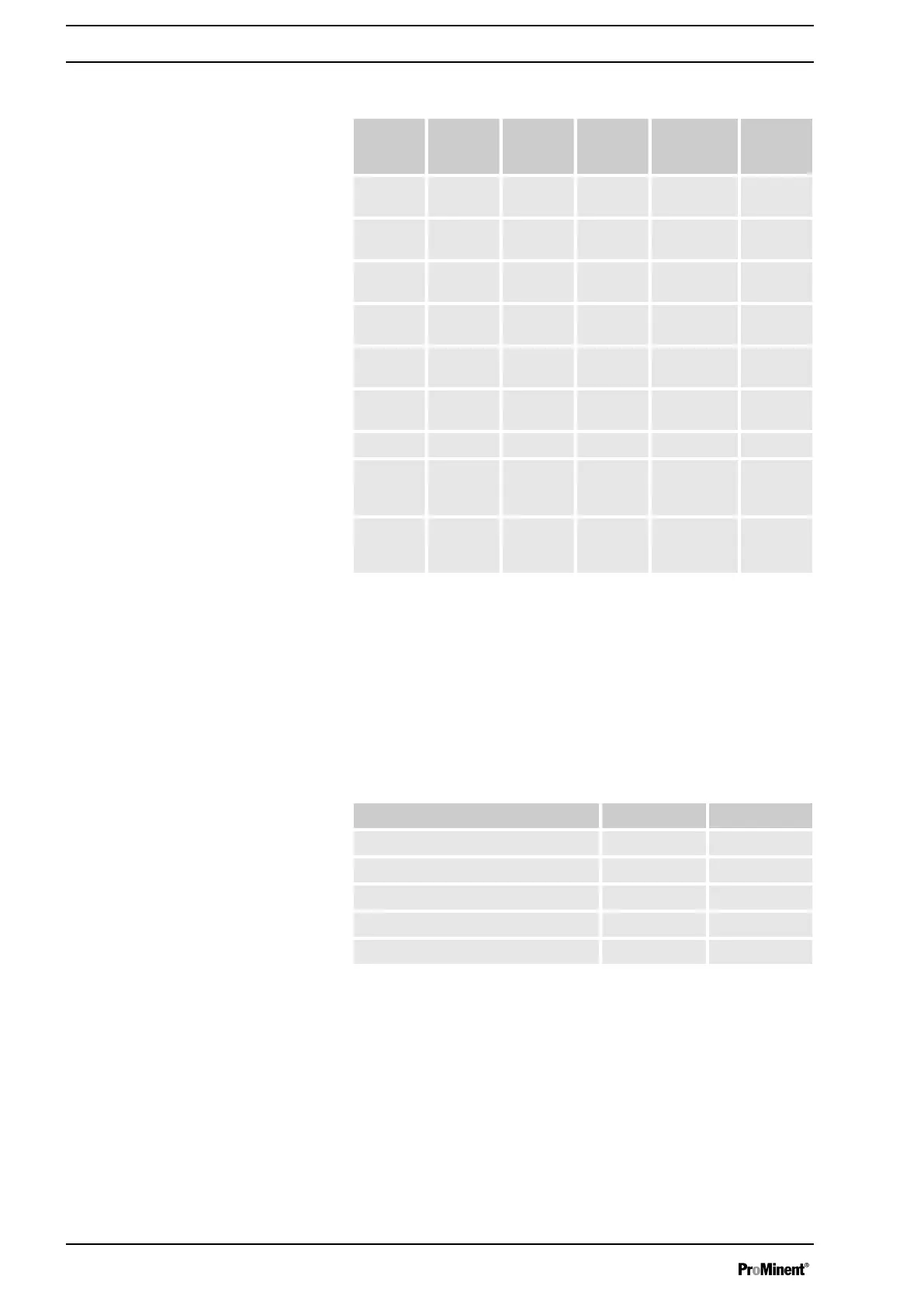

17.5

Electrical Data

Parameter M70 M85

Nominal power**, approx. 25 W 30 W

Current I eff 0.24 … 0.13 A 0.3 … 0.17 A

Peak current 3.5 … 1.3 A 3.7 … 1.5 A

Switch on peak current (for 3 ...5 ms) 20 A 20 A

Fuse* 2.5 AT 2.5 AT

** with relay closed: The nominal power rises by 1 W.

* Fuses must have VDE, UL and CSA certification. e.g. type 19195 manu‐

factured by Wickmann in compliance with IEC Publ. 127 - 2/3

Standard liquid ends

Pump

Design: 100 - 230 V ±10 %, 50/60 Hz,

gamma/ X GMXa

Technical Data

80

Loading...

Loading...