PULSAR MEASUREMENT

25

SENSOR MOUNTING LOCATION

The position of the sensor is one of the most important considerations for accurate flow measurement. The same

location guidelines apply to Doppler as most other types of flow meters.

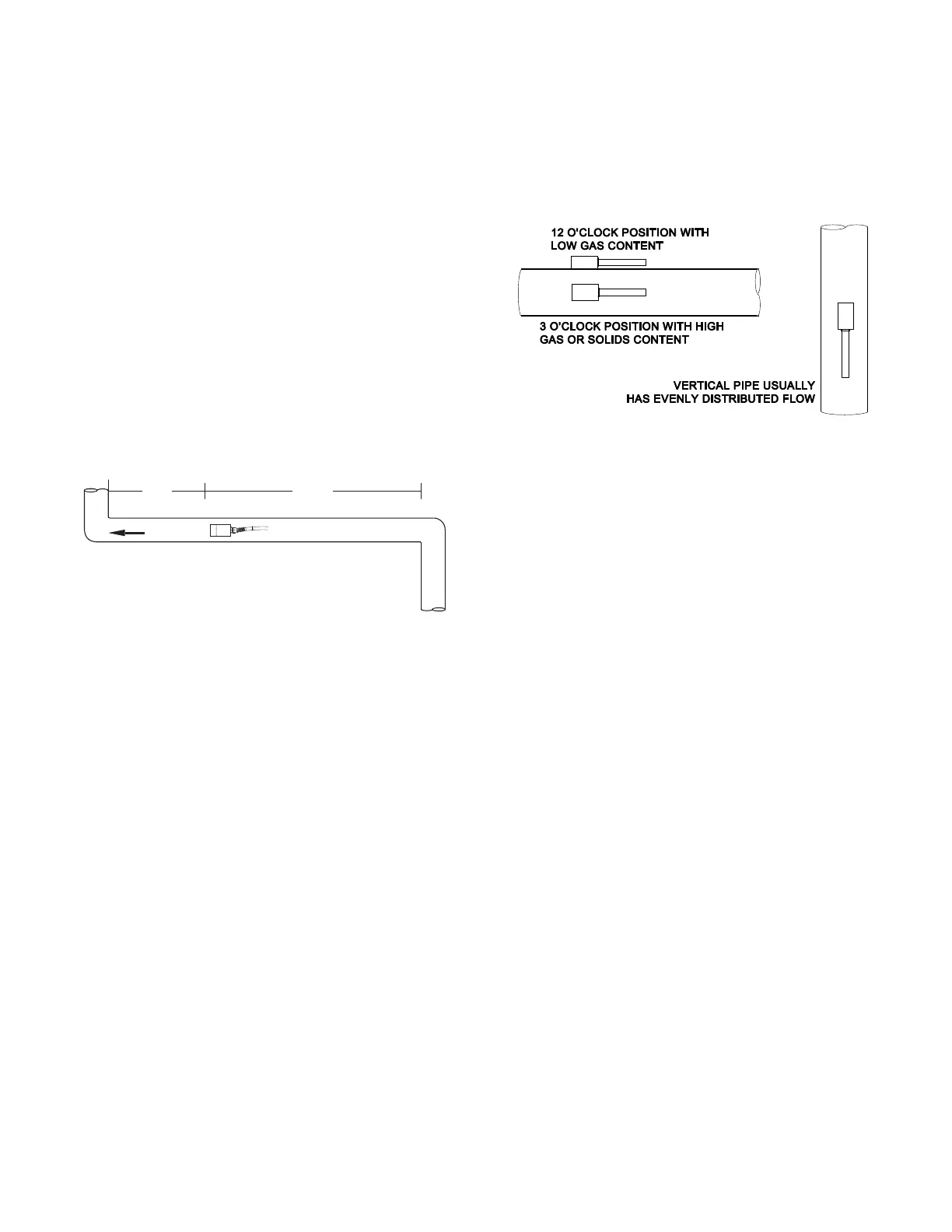

VERTICAL OR HORIZONTAL PIPE - Vertical pipe runs

generally provide evenly distributed flow. On Horizontal

pipes and liquids with high concentrations of gas or solids,

the sensor should be mounted on the side (3 or 9 o’clock

position) to avoid concentrations of gas at the top of the

pipe, or solids at the bottom. For liquids with minimal gas

bubbles (e.g. potable water) the sensor should be mounted

on the top of a horizontal pipe (12 o’clock position) to obtain

the best signal strength.

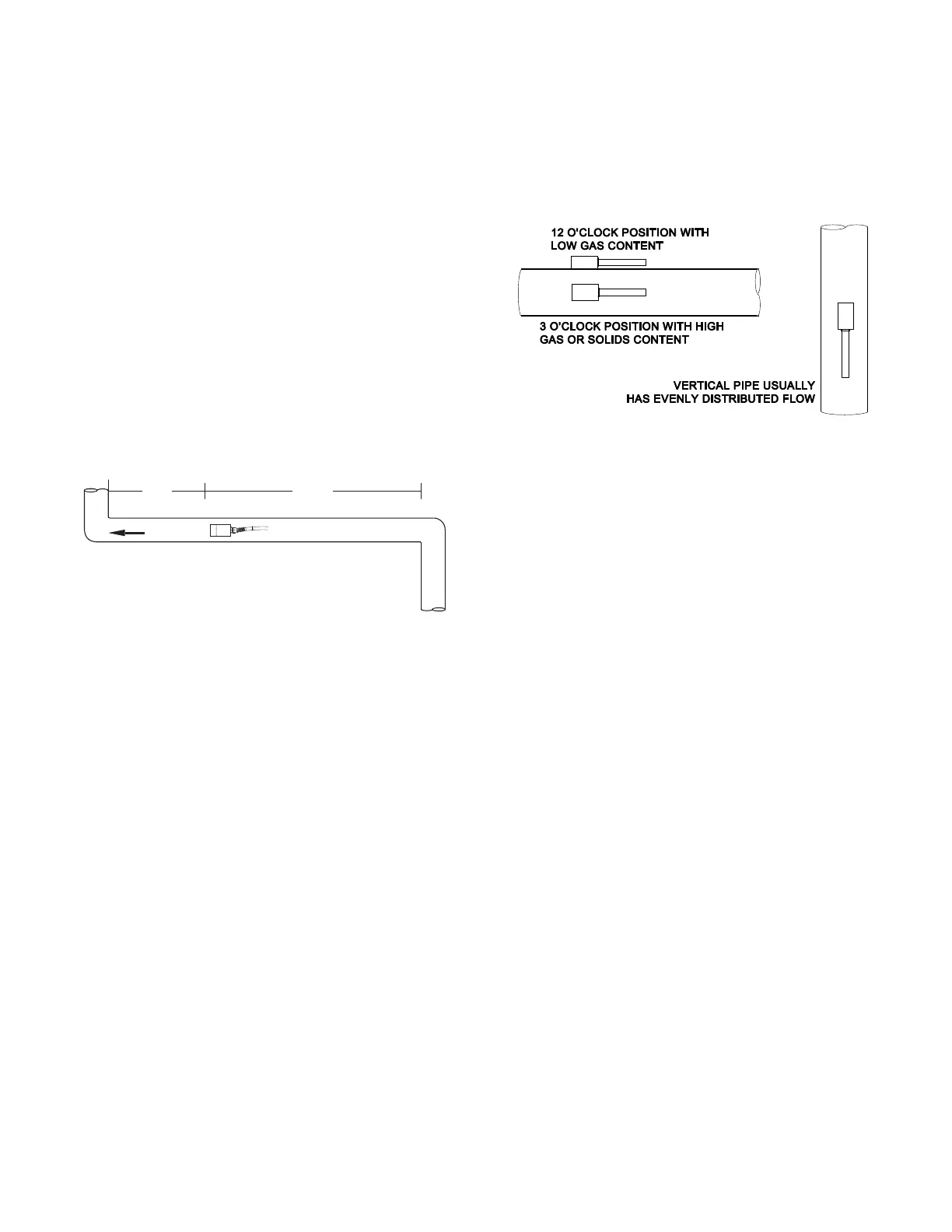

STRAIGHT RUN REQUIREMENTS – For best results, the

transducers must be installed on a straight run of pipe,

free of bends, tees, valves, transitions, insertion probes

and obstructions of any kind. For most installations, ten

straight unobstructed pipe diameters upstream and

five diameters downstream of the transducers is the

minimum recommended distance for proper

operation. Additional considerations are outlined below.

• Do not, if possible, install the transducers downstream from a throttling valve, a mixing tank, the discharge of a

positive displacement pump or any other equipment that could possibly aerate the liquid. The best location will

be as free as possible from flow disturbances, vibration, sources of heat, noise, or radiated energy.

• Avoid mounting the transducers on a section of pipe with any external scale. Remove all scale, rust, loose paint,

etc., from the location prior to mounting the transducers.

• Do not mount the transducers on a surface aberration (pipe seam, etc.).

• Do not mount transducers from different ultrasonic flow meters on the same pipe.

• Do not run the transducer cable in common bundles with cables from other instrumentation. You can run these

cables through a common conduit ONLY if they originate at the same flow meter.

• Never mount transducers under water.

IMPORTANT NOTE: In some cases, longer straight runs may be necessary where the transducers are placed

downstream from devices which cause unusual flow profile disruptions or swirl. For example: modulating valves, or

two elbows in close proximity and out of plane.

5 Dia

10 Dia

FLOW

Loading...

Loading...