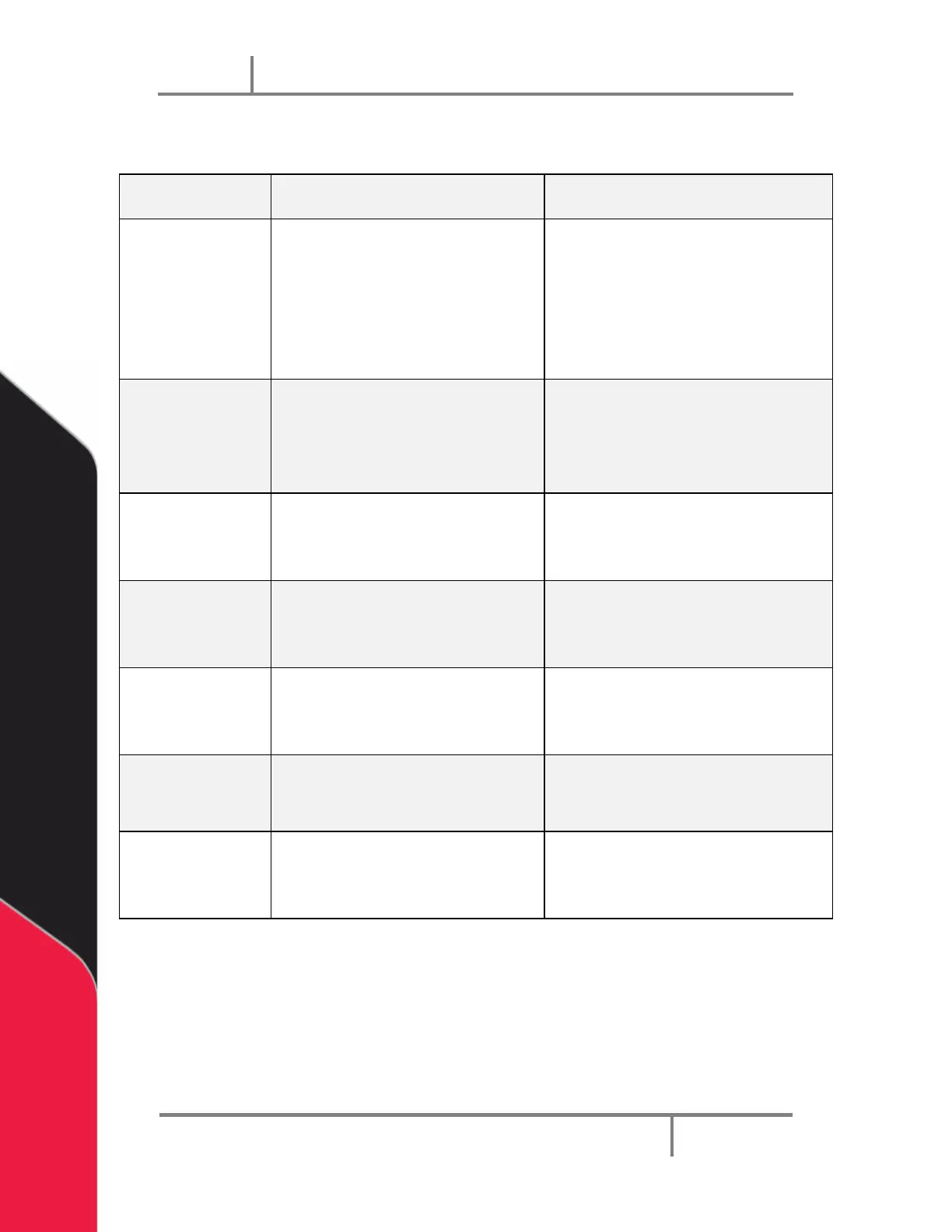

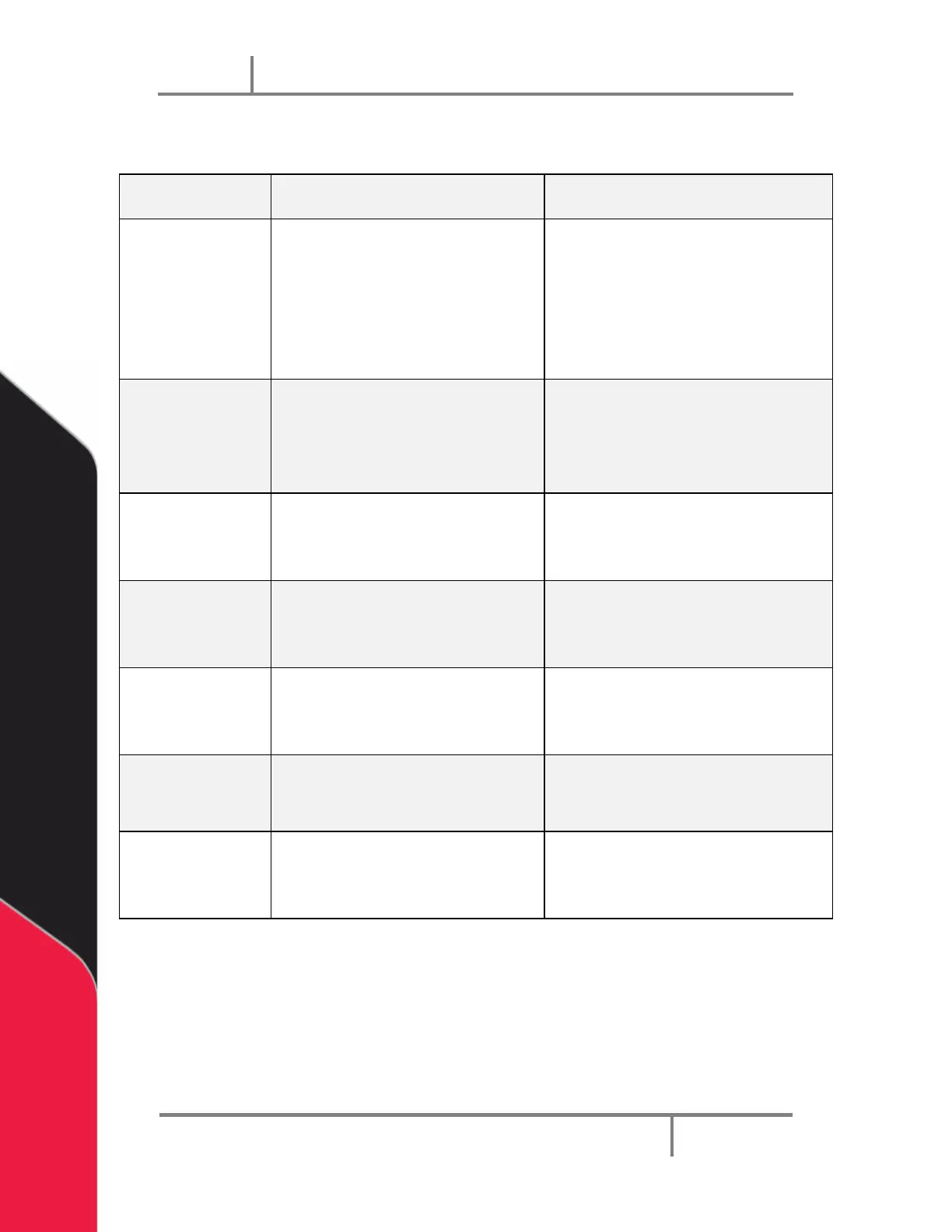

Troubleshooting 10.

Material does not

dispense

•

Material cured in nozzle plate

•

Nozzle plate is clogged

•

material accumulation around

nozzle

•

Heater may be too hot, decrease

temperature. Disassemble and

clean nozzle

•

Disassemble and clean nozzle

•

Clean outside of nozzle with wipe or

vacuum purge

Material leaks

from the nozzle

plate

•

Jet pressure is too low

•

Diaphragm is worn or dirty

•

Nozzle plate is worn or dirty

•

Increase Jet pressure. Max is 65 psi

•

Clean or replace diaphragm

•

Clean or replace nozzle plate

Material leaks

from between the

diaphragm and the

•

Diaphragm is worn or dirty

•

Nozzle plate is worn or dirty

•

Clean or replace diaphragm

•

Clean or replace nozzle plate

Material leaks

from material feed

tube

•

Material feed tube is not attached

correctly

•

The material feed tube is worn

•

Push the material feed tube on so

that it is tight

•

Replace the material feed tube

Material splatters

•

Jet pressure is too high

•

Decrease jet pressure

•

Increase distance to target

substrate

Diaphragm swells

•

Diaphragm material and dispensed

material are not compatible

•

Replace the diaphragm with a

diaphragm made of a compatible

material

Dispense size is

inconsistent

•

Nozzle is clogged

•

Material thickens when static

•

Disassemble and clean nozzle

•

Run pre-dispense routine or

increase first drop setting

Loading...

Loading...