nVent.com/RAYCHEM

|

35RAYCHEM-OM-EU2032-NGCUIT3EX-EN-2203

The Min Ambient Temp is the “lowest ambient temperature” that was used when the heat-tracing system was designed. The entered

value should agree with the value used by the design engineer to ensure that the heating-tracing system was sized correctly.

Range Elexant 5010i / NGC-20: –73°C (–99°F) to 51°C (124°F)

Range NGC-30: –73°C (–99°F) to 51°C (125°F)

Default: –40°C (–40°F)

Min. Pipe Size is the diameter of the smallest heat-traced pipe in the group controlled by this Circuit. Small diameter pipes heat up

and cool down more rapidly than larger diameter pipe. Therefore, the PASC duty cycle is calculated over a shorter time base. Larger

diameter pipes heat and cool less rapidly, so the on/off periods for the heater system can be stretched over a longer period. If

electromechanical contactors are being used to control the heater circuit, the longer time base reduces the number of contactor on/

off cycles and extends the contactor life.

List: 0.5, 1, >= 2 inches

Default: 0.5 inches

This allows the PASC control to be adjusted when the heating cable output is greater than the design assumption, or if the pipe

insulation proves to be more efficient than assumed. Pipe temperature may run higher or lower than desired if the heating cable has

a different output than required to offset the heat loss. The Power Adjust parameter enables a reduction or an increase in the heat-

tracing effective power by entering a value less or greater than 100%

IMPORTANT: If improperly used, the Power Adjust parameter can cause the piping to get too cold or too hot. If unsure, leave at 100%.

Do not change this value unless an engineer calculates the temperature impact on the system and determines that it is safe to do so.

Be particularly cautious if the circuit has more than one diameter of pipe or type of heat tracing. Contact a nVent representative for

assistance with this factor.

Range: 10–200%

Default: 100%

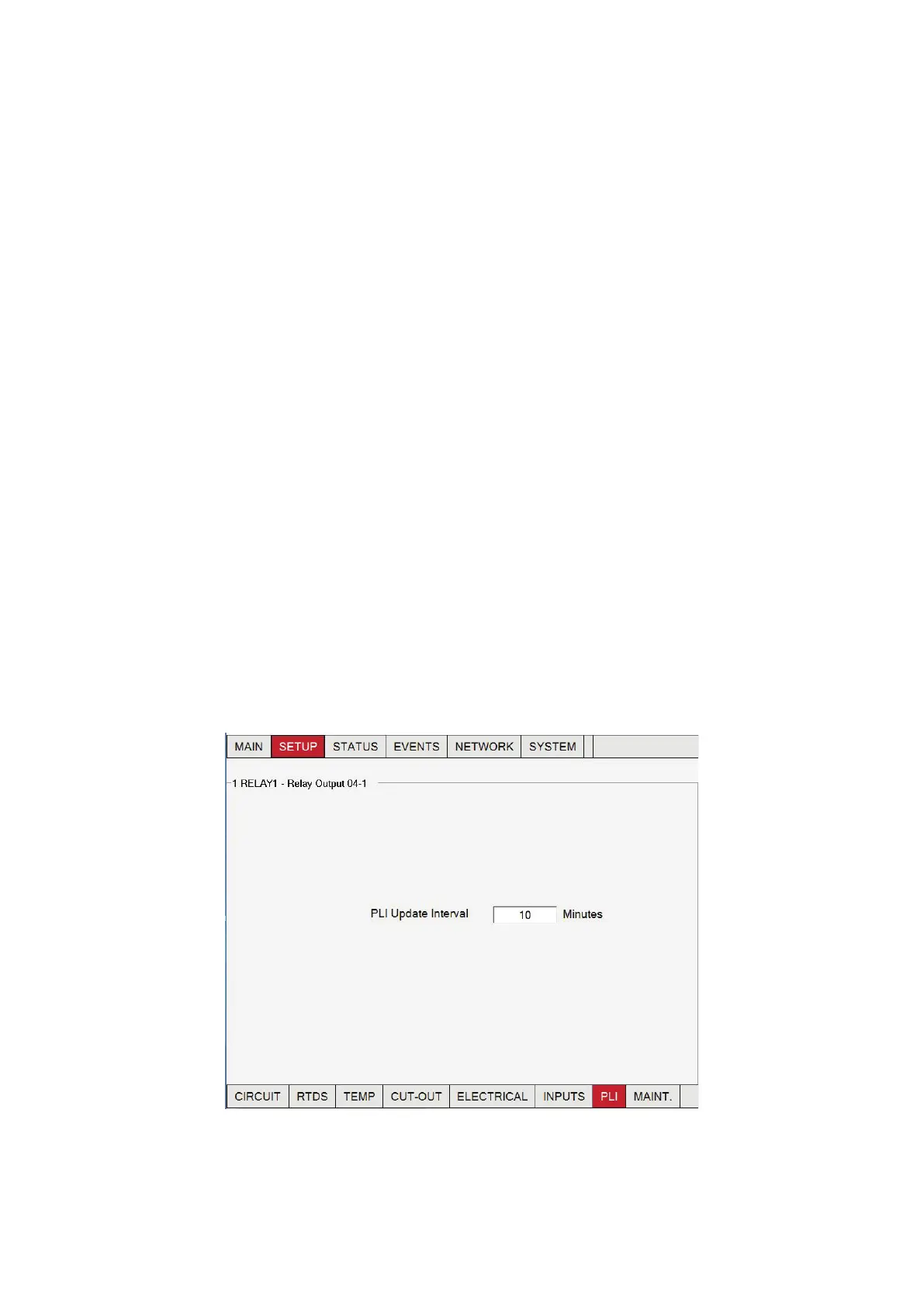

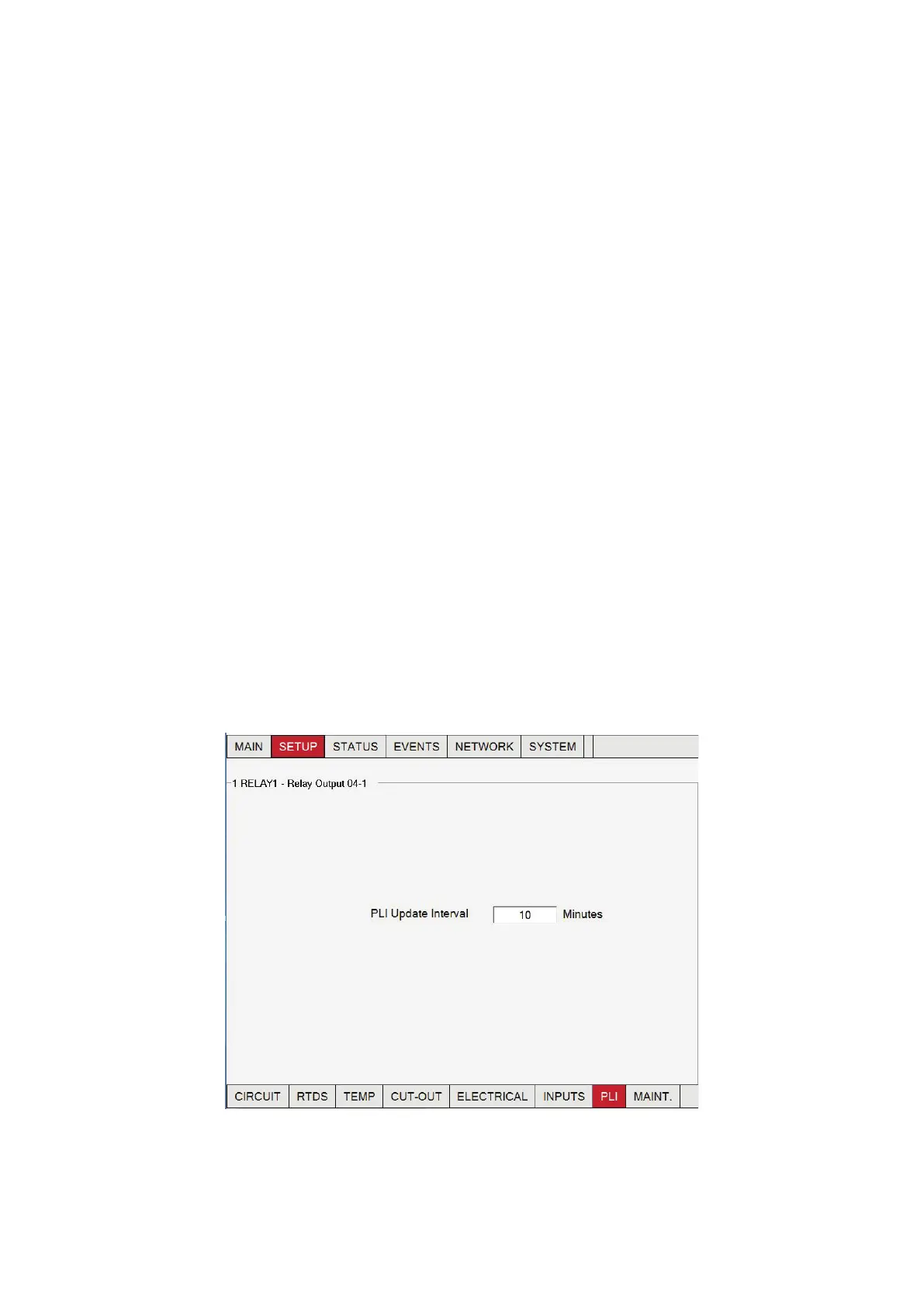

This window allows you to set the update time when using an PLI. The update time, in minutes, is used as the time that is waited

before polling the sensor(s) for a new temperature on a circuit after the circuit has turned off. The sensors are continuously polled

while the circuit is on.

Fig. 3.16 Setup | PLI window

- When the heating cable is ON, the temperature measurements will be transmitted from the SES and SPC transmitters

to the PLI module/NGC-30 controller approximately every 5 to 11 minutes depending on the SES address. When using 700-TT

transmitters, the temperature data will be polled periodically. The time interval is within minutes and depends on the number of 700-

TT transmitters and the number of connected circuits.

Loading...

Loading...