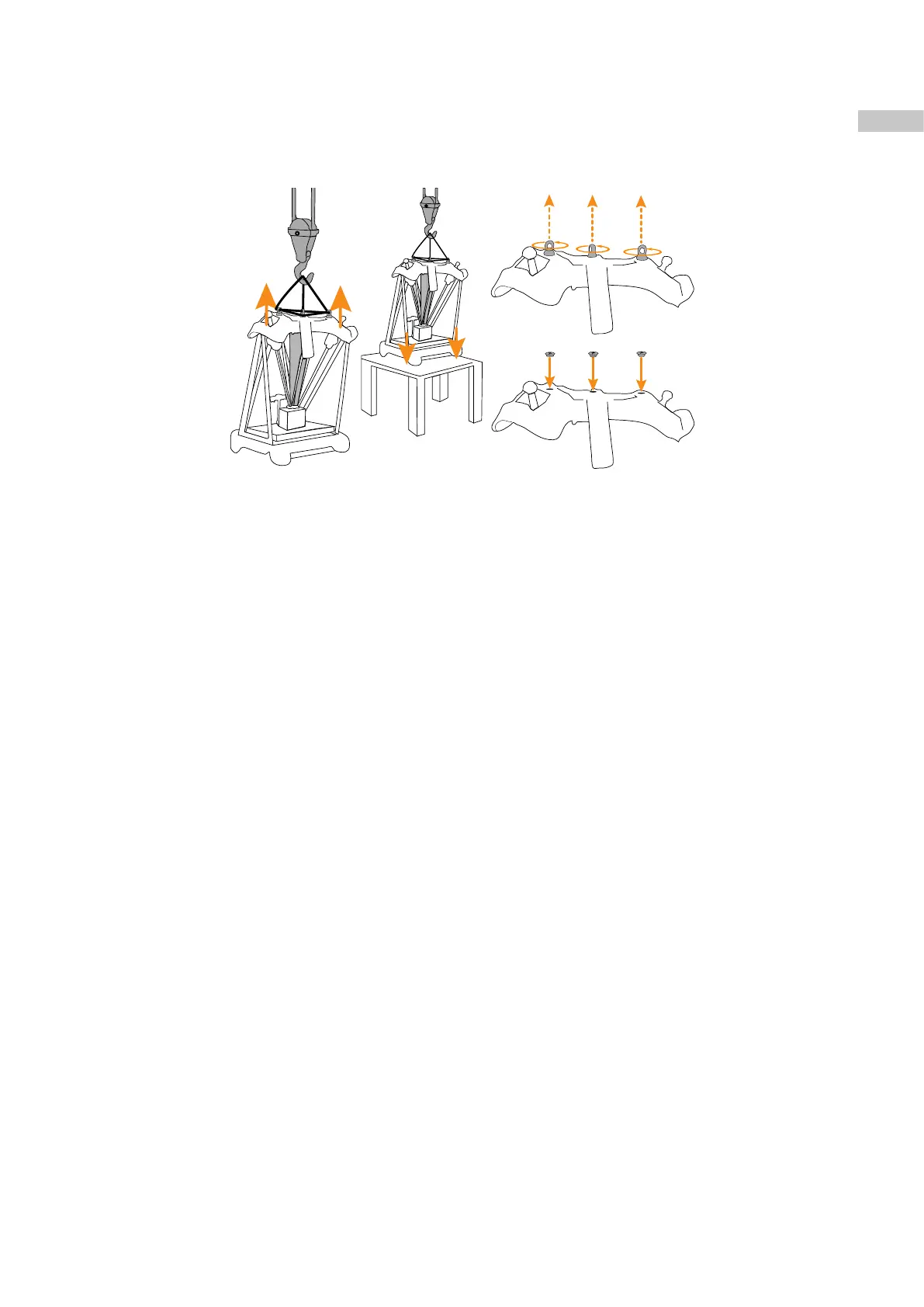

• The weight of the Equator 500 unpacked is 74 kg and therefore it is advised that the machine is only lifted

using mechanical means. A high lift pallet truck can be used under the machine base, or a lifting arm can

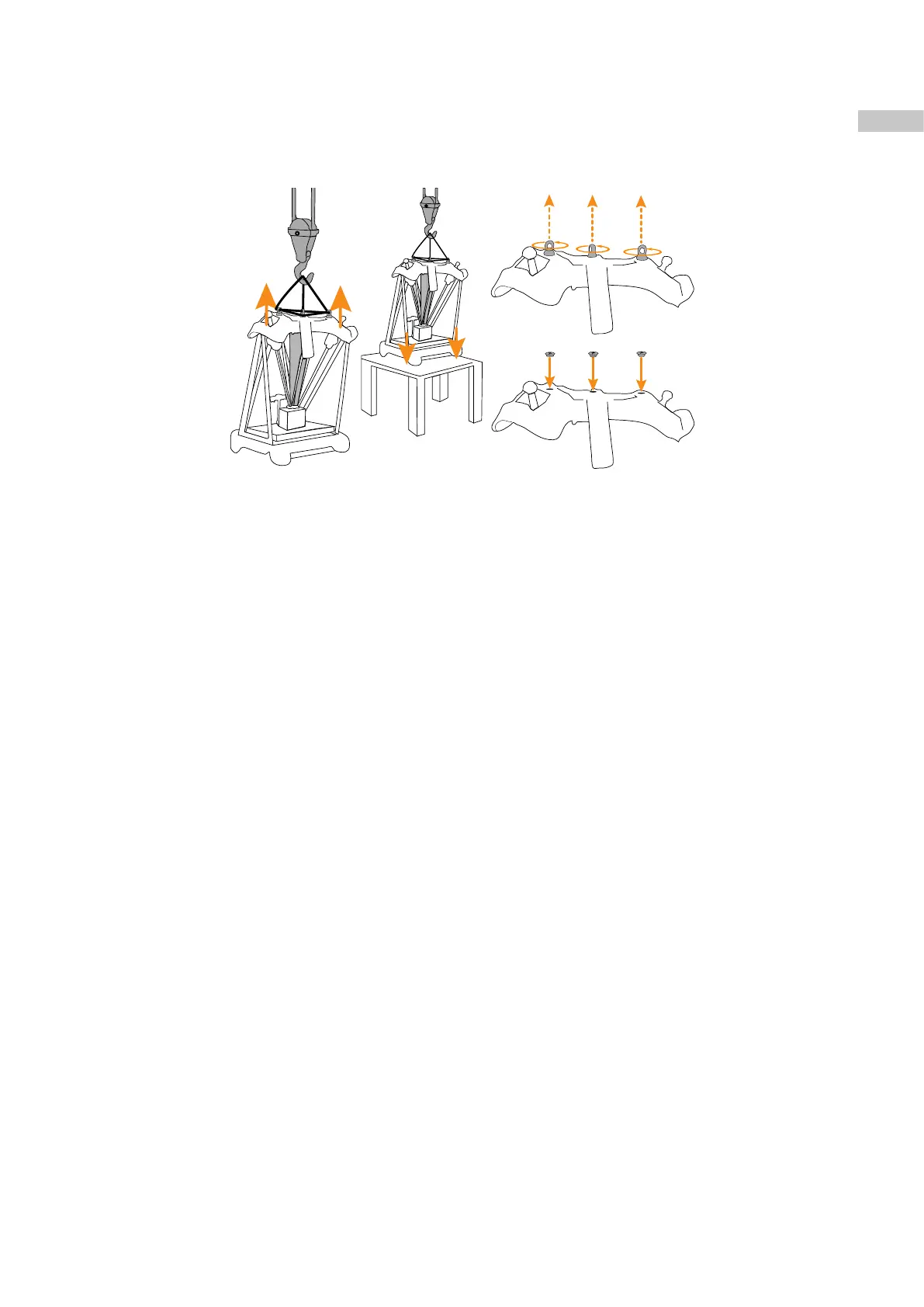

be used with the supplied eye bolts from the top casting. Once in position, the eye bolts can be removed

and the supplied blanking caps inserted.

• If inserting pallet truck forks under the base, be careful of drain pipe and cable clip locations, and ensure

that the forks are properly supporting the base, i.e. inserted fully past the casting.

• The Equator 500 should only be mechanically lifted using, for example, a gantry crane, forklift, etc. There

are eye bolts (16) on the top casting of the Equator 500 to allow for the use of lifting straps or a harness.

Each eye bolt supplied with the Equator 500 has been rated to a safe working load of 240 kg, and

manufactured to DIN 850. Renishaw only guarantees the integrity of the eye bolts supplied for the initial

installation of the unit. Should you wish to use this equipment for subsequent lifts, it is your responsibility to

ensure it is inspected in accordance with local legislative requirements before use.

• Do not move or lift the machine by the support arms for the constraint mechanism (9), the support struts

(4), or the three drive struts (6) (for example, by holding the orange protectors or any part of the drive strut

mechanism).

• Potential finger traps and pinch points exist between:

• support arm (9) and casting (5);

• support arm (9) and constraint mechanism (12);

• upper pivot (8) and drive strut (6);

• platform (3) and piece part (14);

• platform (3) and constraint mechanism (12);

• the struts of the constraint mechanisms (12) in the centre.

Users should not touch the Equator in these locations.

• To warn users of potential risks involved with moving parts, active parts are coloured bright orange (3), (6),

(7), (9).

• The EQ500 drive includes a physical brake that will engage if the power to the machine is lost, the stop

button is pressed or under certain other error conditions. Do not try to backdrive the platform, as either the

brake or the drives will be engaged and damage to the machine may occur. Only move the machine using

the joystick, button interface or programmatically.

• When in packaging the brake is not activated so it is possible to move the platform carefully by hand.

However upon first power-up, the brake will activate and from that point on, the brake will come on as

described above.

• When connecting a joystick, stop button or Button Interface (15) to the Equator, it must be disconnected

from the mains power supply. Not doing so can cause damage to the circuitry.

• Never keep an additional non-connected joystick, stop button or Button Interface (15) in the vicinity of the

system to avoid user confusion.

33

Loading...

Loading...