In addition to the instrument settings, the filling level of the grinding jar is also of crucial

importance for a successful grinding process in the Planetary Ball Mill of Retsch GmbH. When

grinding bulk materials, the grinding jar filling should consist of approximately one third

of sample and one third of ball quantity. The remaining third is the free grinding jar volume,

which is required for the movement of the balls.

If an increase or decrease in sample volume is to be expected during the grinding process, the

amount of sample can be adjusted within the range listed in the table. Thus, e.g. for voluminous

materials such as wool, leaves, grasses and similar, a material filling level of 70 – 80 % is

necessary. For wet grinding with grinding balls < 3 mm, the ball charge should be 60 % of the

grinding jar volume.

5.16 Ultrafine grinding

High degrees of fineness can frequently only be achieved using wet grinding.

Improved final fineness can be achieved in dry grinding by adding a few drops of stearin or

acetic acid and by using grinding balls with a Ø<10mm and a fill level of 70-80% of the grinding

jar volume.

5.17 Stacking the grinding jars

5.17.1 Stacking the 50ml grinding jars

NOTICE

It is not possible to stack 50ml grinding jars in the PM200.

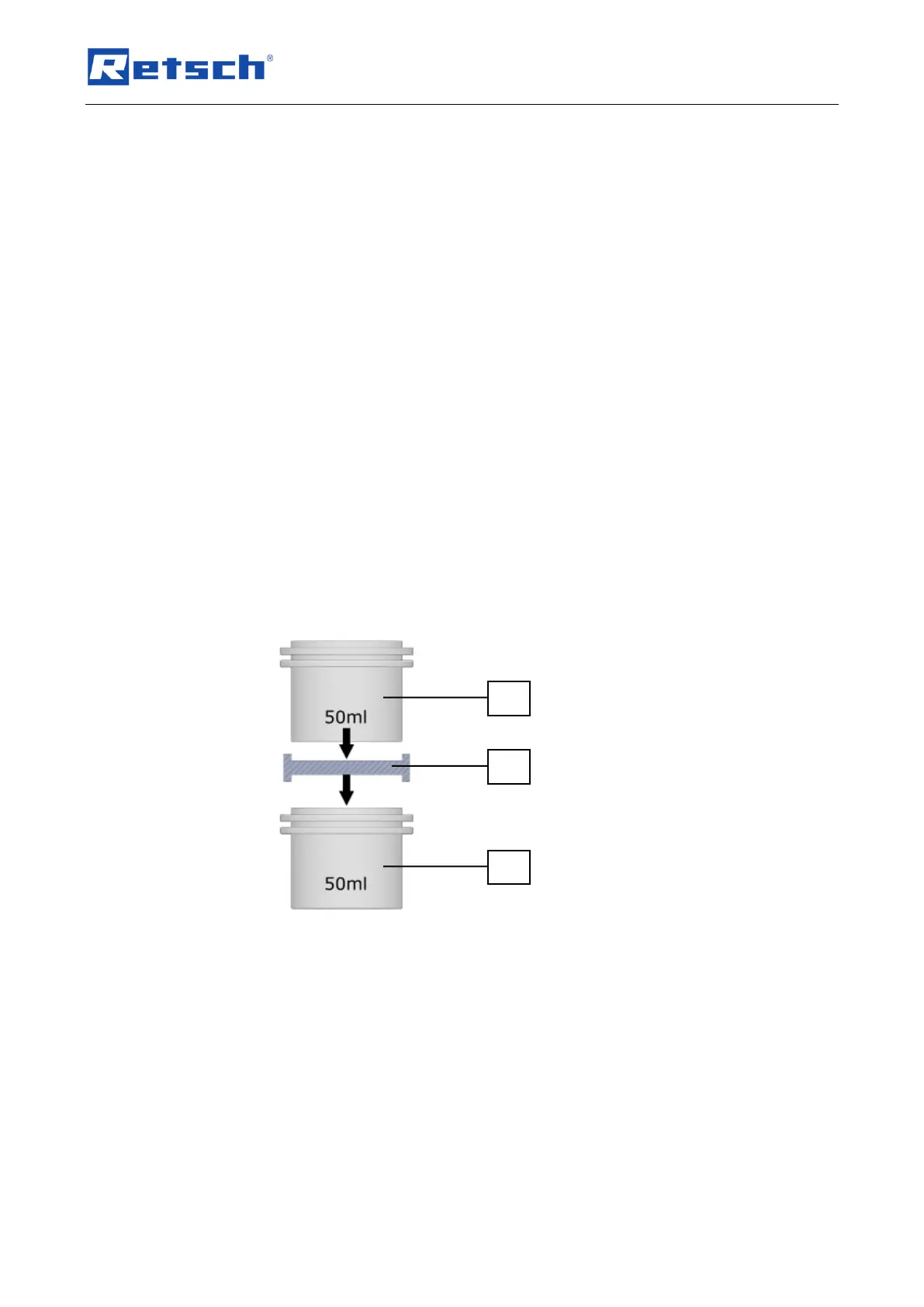

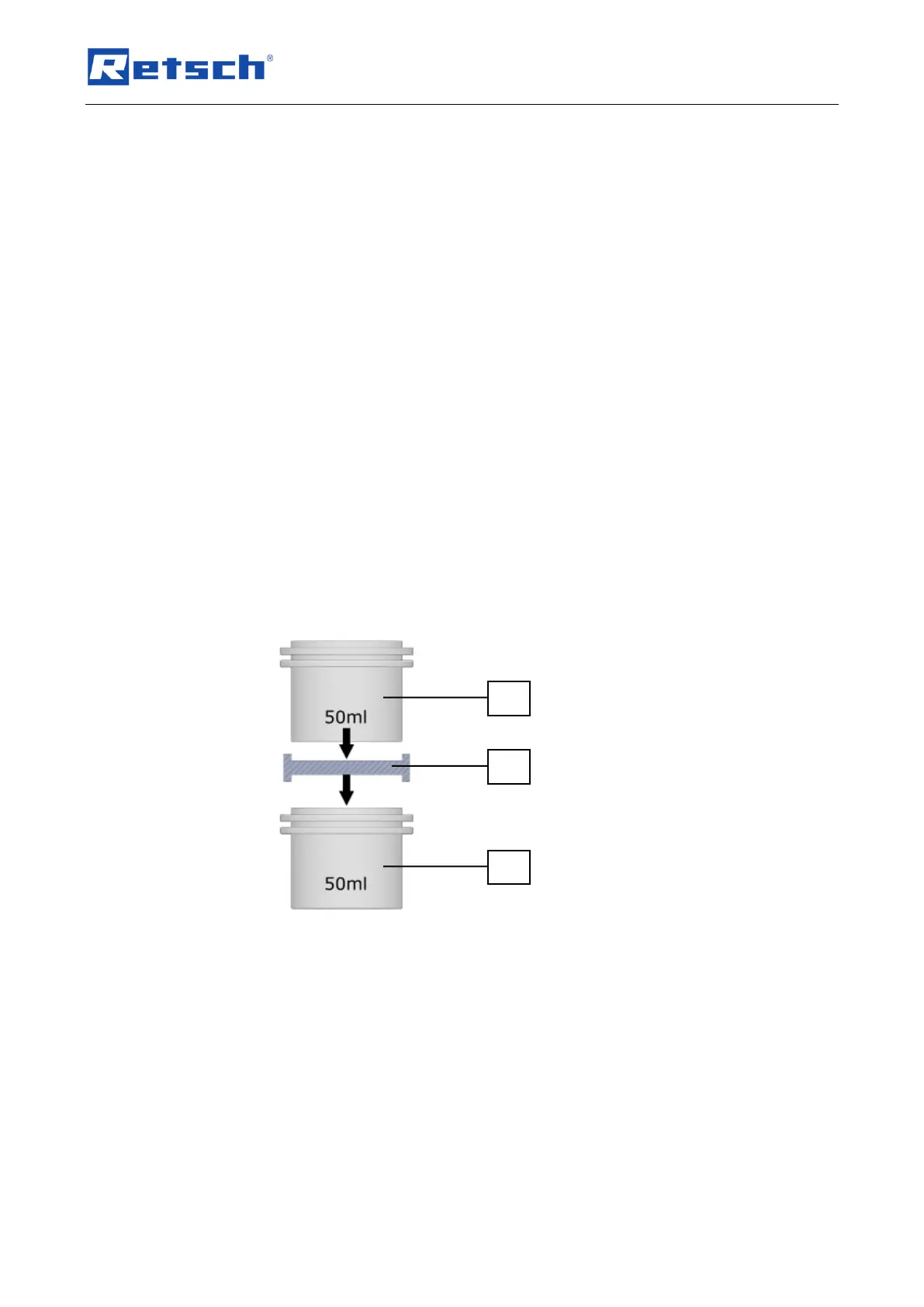

Fig. 24: Stacking 50ml grinding jars on the PM100 and PM100CM

You can also stack two 50ml grinding jars on top of one another.

You will need the optional adapter to stack the grinding jars.

Stacking process:

• Place the grinding jar (M1) in the grinding jar plate

• Place the adapter (A1) on the lid of M1

• Place grinding jar (M2) on the adapter

• Clamp the grinding jars as described in the chapter “Clamping the grinding

jars”.

Loading...

Loading...