REYMSA COOLING TOWERS, INC.

www.reymsa.com

The

All-Fiberglass

Cooling Towers

21

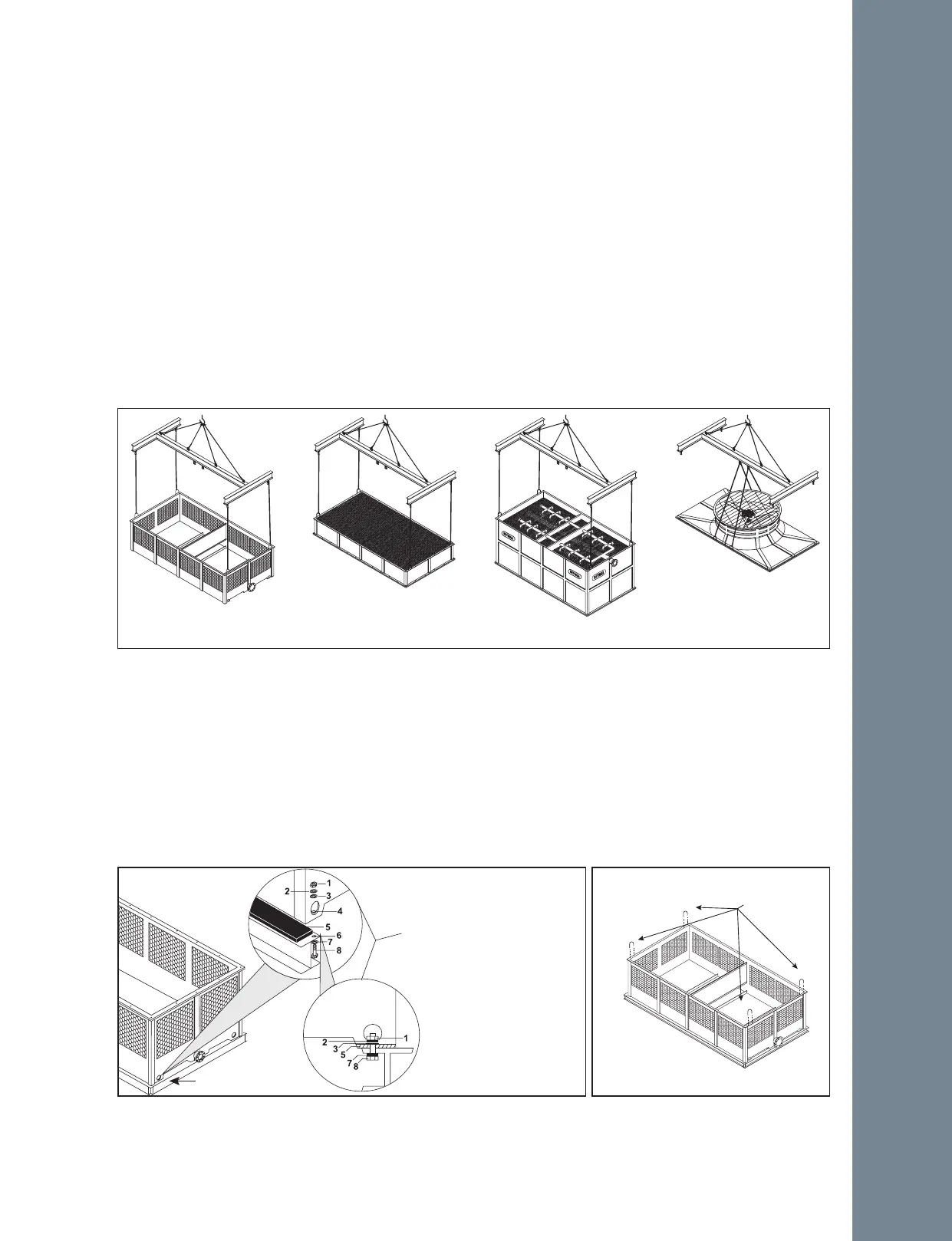

A.4 ASSEMBLY INSTRUCTIONS FOR RTG MODELS

Follow this procedure to assembly and install an RTG Cooling Tower. Use drift pins to align bolt holes and

use the galvanized bolts provided to torque the sections together. Replace galvanized bolt with stainless

bolts after sections are secured together.

A. Upon the arrival of the equipment to its final destination, check for any abnormality or apparent damage

on the packaging before unloading the Cooling Tower from the transportation vehicle.

B. After assuring the equipment is received in proper condition, proceed to unload it from the transportation

vehicle, piece by piece, with a crane (using a spreader bar) or forklift of the appropriate capacity, see

Figure A-46 for an example.

C. For crane lifting, it’s recommended to use a minimum lifting angle of 60º between the strap and the

horizontal. Each section of the Tower has U-bolts for lifting. Place the straps through the U-bolts (as shown

in Figure A-46) and use a spreader bar to avoid damage on the upper edge of the Tower. Don’t balance

until tensing the straps.

D. Remove the plastic wrap that surrounds the Tower and its components, and loosen the nuts and bolts that

keep the body & basin attached to the wooden pallet (those located at the bottom of basin).

E. Before Tower’s assembly, REYMSA recommends to install a steel base structure that supports the Tower’s

operational weight; also place an isolation pad (supplied by others) between the Tower and the base

structure for support purposes. Verify that the base structure has the proper dimensions (for construction,

refer to factory certified drawings). For more information, see section “A.11.1 LEVELING AND TOWER

SUPPORTS”.

Figure A-46: Crane lifting for an RTG model.

Basin Section

Lower Body Section

(only RTG-D & RTG-E)

Upper Body / Body Section

Fan Deck

Steel base structure

(Supplied by others)

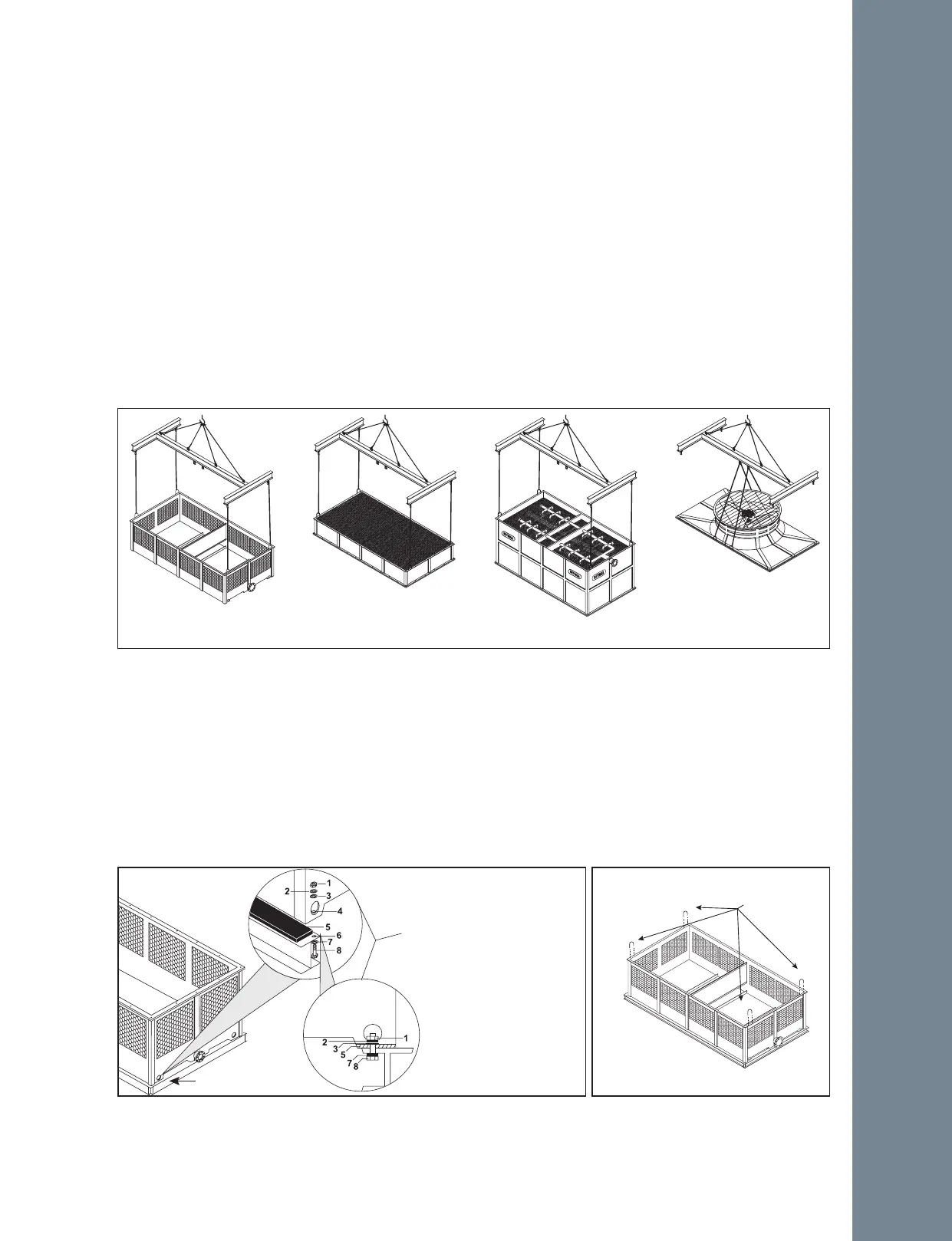

Figure A-47: Typical anchorage for an RTG model.

4 ANCHORAGE HOLES

(ONE ON EACH CORNER)

1. 3/4” Nut

2. 3/4” Lock Washer

3. 3/4” Flat Washer

4. 3/4” Anchorage Holes

5. Isolation Pad

6. ≈1” Hole

7. 3/4” Flat Washer

8. 3/4” X 3” Bolt

(Supplied by others)

Figure A-48: Removing U-bolts from

basin section of an RTG model.

Remove

Installation

Loading...

Loading...