REYMSA COOLING TOWERS, INC.

www.reymsa.com

The

All-Fiberglass

Cooling Towers

75

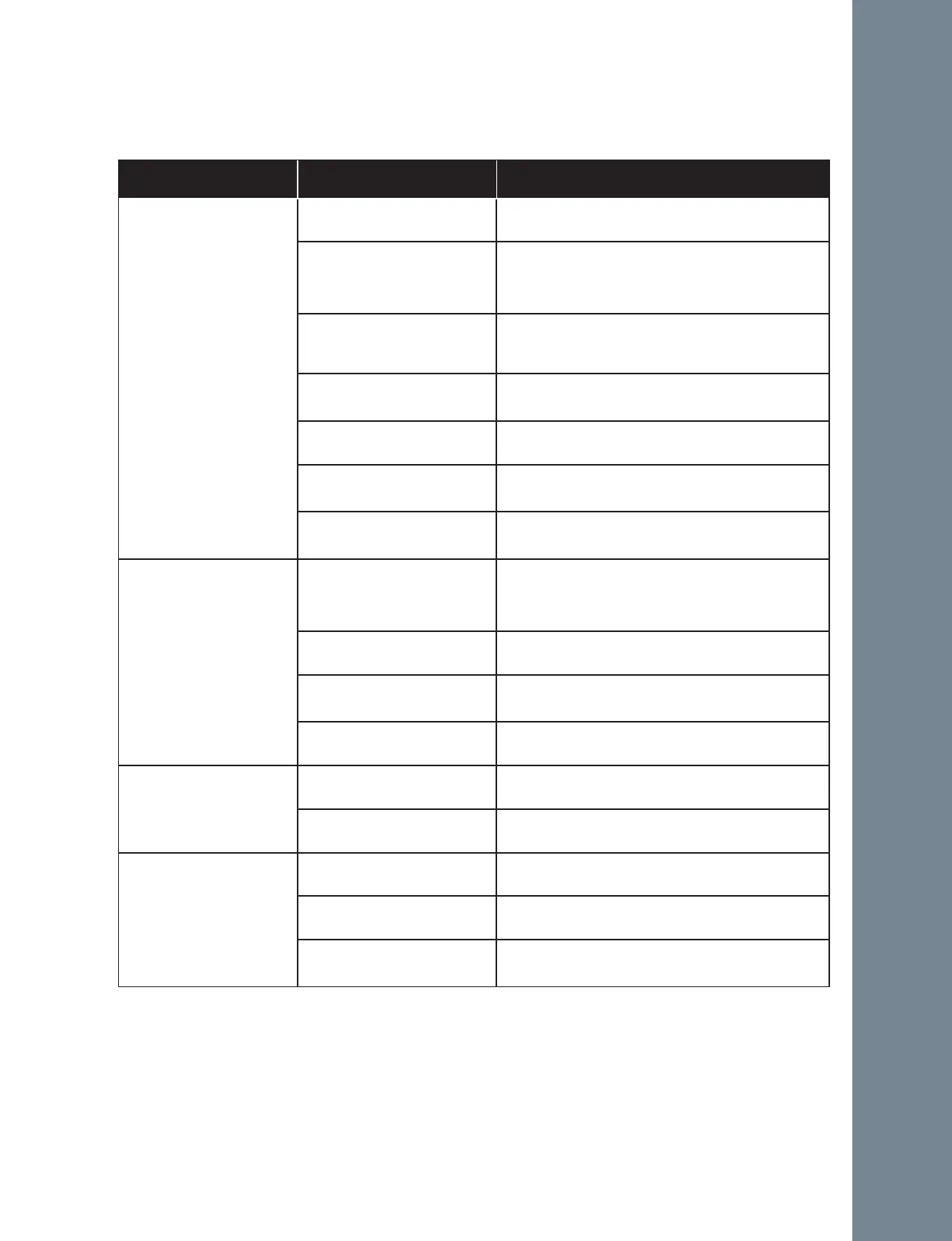

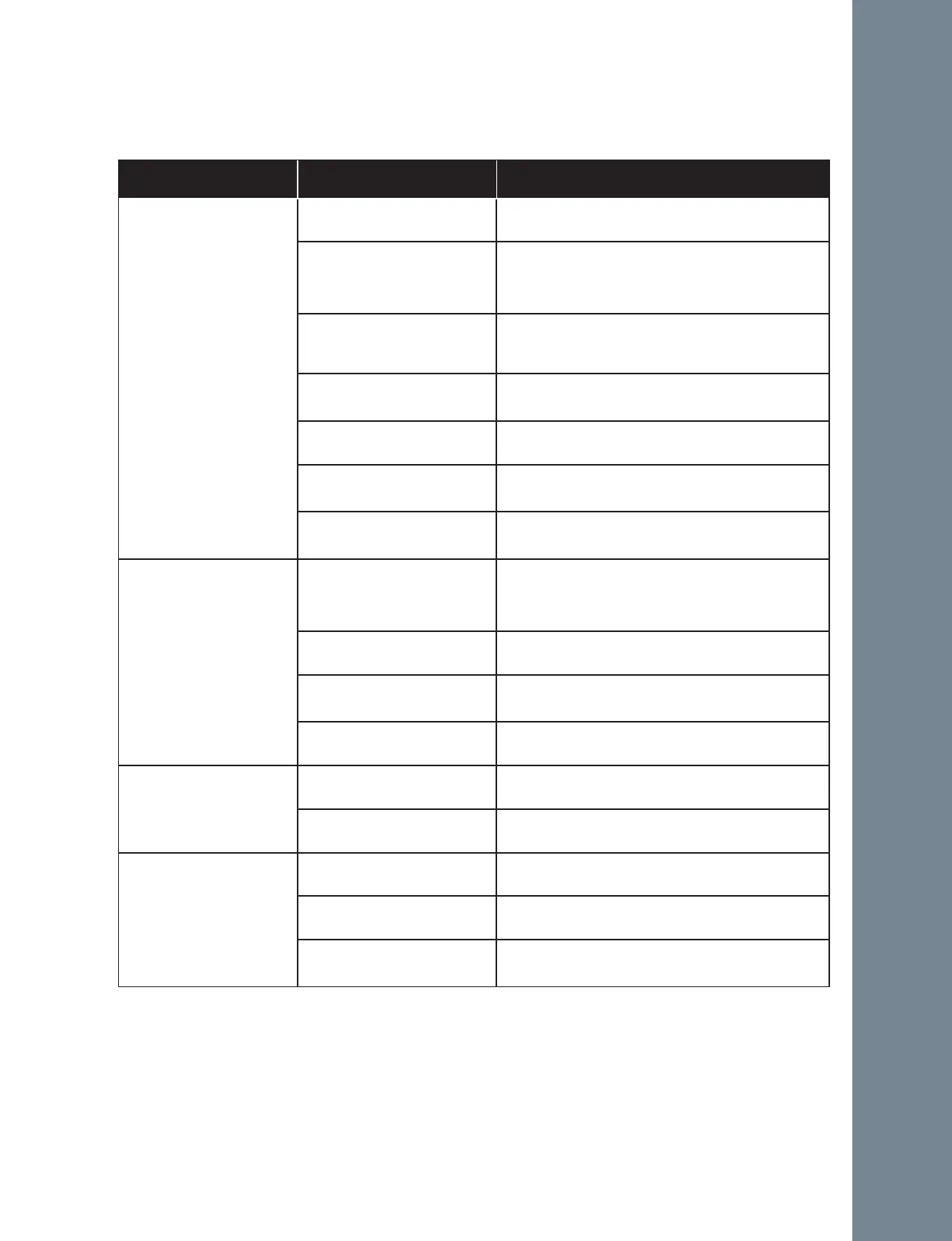

E. TROUBLE-SHOOTING

PROBLEM / SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Exiting water temperature

is too high

Excessive water flow Adjust the water flow rate to design value

Insufficient air flow Clean fill media and drift eliminators. Verify that

the amperage is not less than 10% than shown on

the data plate of the motor. If so, pitch of the fan

blades needs to be adjusted, call your REYMSA

Representative for assistance

Higher heat load through

Tower that designed for

Compare actual heat load versus design heat load.

Contact your REYMSA representative for advice on

possible upgrade or addition of another Cooling

Tower

Recirculation of hot discharge

air back into Cooling Tower

air inlet.

Eliminate obstructions that impede correct air

discharge or call your REYMSA representative for

advice

Higher Wet-bulb Temperature

than design.

Consult your REYMSA representative

Improper operation of the

water distribution system

Perform cleaning on the entire system (see

maintenance procedure, section “D.2 BASIN” of this

manual)

Heat transfer system

obstruction.

Inspect and make the proper cleaning and

maintenance, if required (see maintenance

procedure, section “D.2 BASIN” of this manual)

Unusual noises when the

Tower is operating

The propeller fan might be

scraping against the side of

the fan duct

Remove the fan guard to obtain access to the

propeller. By hand, check to see that the propeller

moves freely and that there are no indications of

mechanical problems with the motor. If so, call your

REYMSA representative for assistance

The motor is having

mechanical problems

Have the motor checked by qualified personnel

Misalignment, friction or

unstable mounting of Gear

Reducer or Drive Shaft.

Check alignment of all components. External

fasteners should be checked for tightness. Check oil

level.

Vibration of the fan wheel Perform a dynamic balance of the fan wheel by

qualified technical personnel

Pump cavitation

Low water operating level Adjust the water make-up valve to raise the

operating water level

Make-up valve malfunction Verify that water is available to the make-up valve.

Repair or replace the make-up valve

Low cold water flow rate

Clogged nozzle(s) Check spray nozzles and clean or replace as

required

Low water level on the basin Check water level control and adjust if necessary

The flow of water through

the water outlet strainers is

obstructed

Inspect and make the proper cleaning and

maintenance, if required (see maintenance

procedure, section “D.2 BASIN” of this manual)

Trouble-Shooting

Loading...

Loading...