Drum Charge

D017/D018/D019/D020 6-36 SM

Vsdp. This voltage is compared with Vsg (read from the bare drum at the same time).

If the humidity drops, the drum potential goes up (to a higher –ve voltage) even if the

charge roller voltage supply stays the same (efficiency of voltage transfer is higher with

lower humidity). As a result, less toner is transferred to ID sensor pattern [B]. If the sensor

output reaches a certain point, the drum charge voltage will be reduced.

To determine whether to change the drum charge roller voltage, the machine compares

Vsdp with Vsg.

Vsdp / Vsg > 0.95 = Reduce the magnitude of the drum charge voltage by 50 V

Vsdp / Vsg < 0.90 = Increase the magnitude of the drum charge voltage by 50 V

6.8.3 ID SENSOR PATTERN PRODUCTION TIMING

The ID sensor pattern is made in the following conditions:

When the machine is turned on or returns from the energy save mode and the hot

roller temperature is less than 30 °C. The temperature threshold can be adjusted with

SP2995 001

After the total number of prints exceeds 300 pages. If this total is exceeded during a

job, the pattern is created at the completion of the job. This total can be changed with

SP2995 002.

SP 2995 003 determines whether the job is interrupted to make the ID sensor pattern.

If it is set to 1, the job will be interrupted.

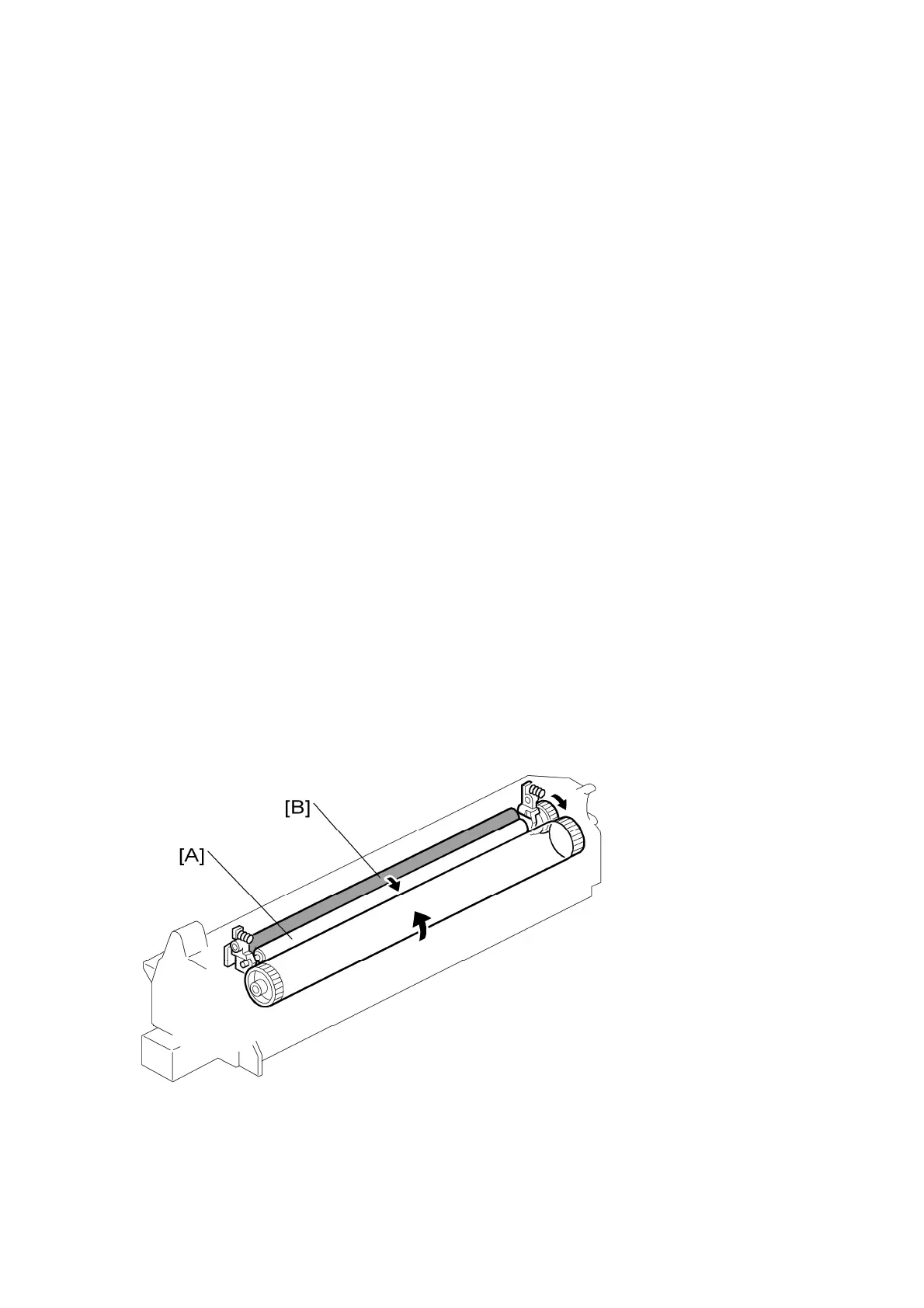

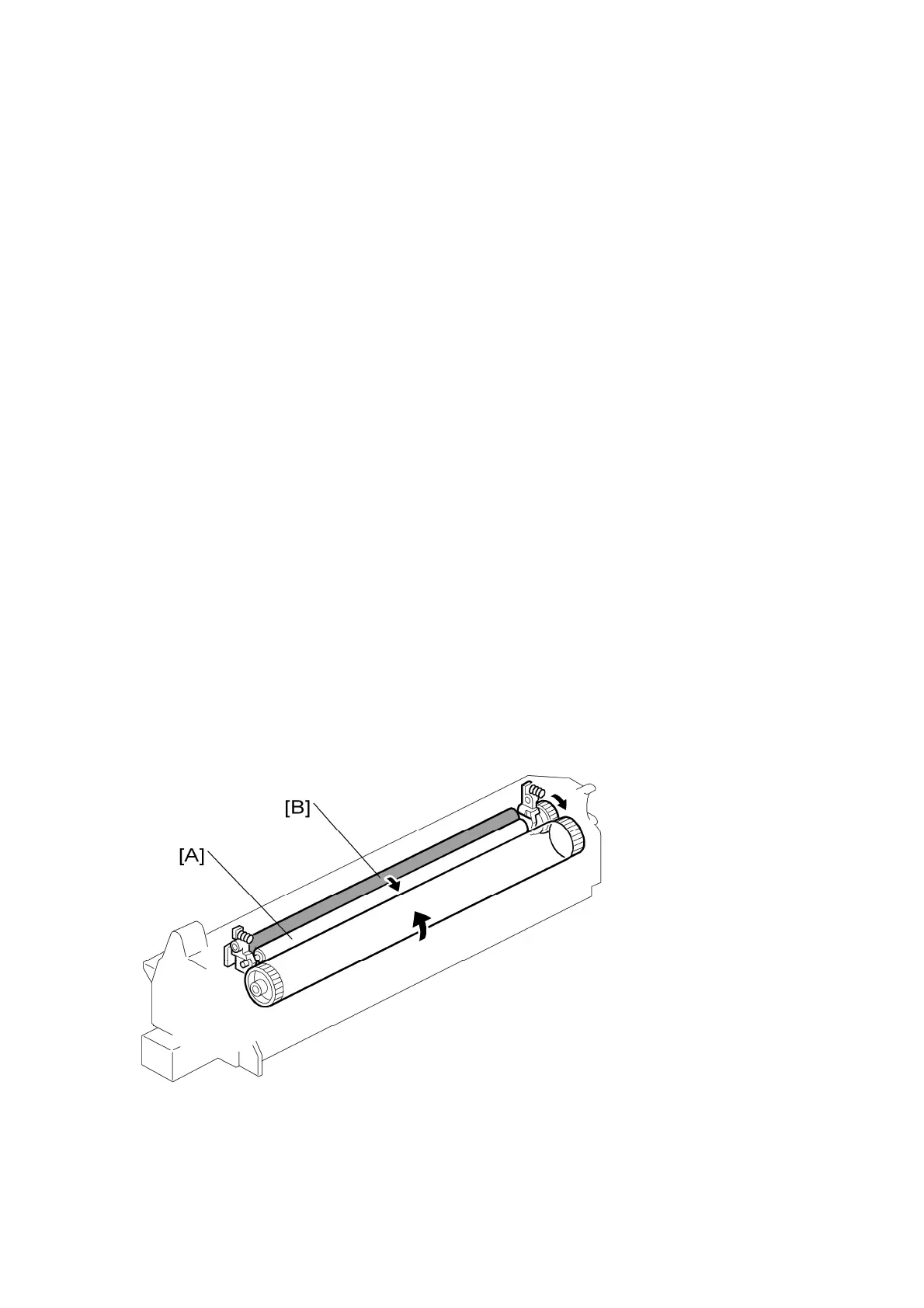

6.8.4 DRUM CHARGE ROLLER CLEANING

Because the drum charge roller [A] always contacts the drum, it gets dirty easily. So, the

charge roller cleaning roller [B] also contacts the drum charge roller all the time to clean the

surface of the drum charge roller.

Loading...

Loading...